Plastic dipping liquid for anti-aging clothes hangers

An aging-resistant and plastic-dipping technology, used in coatings, fire-retardant coatings, polyester coatings, etc., can solve problems such as cracking, falling off, and the inability to continue to protect hangers, and achieve strong adhesion, high insulation, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

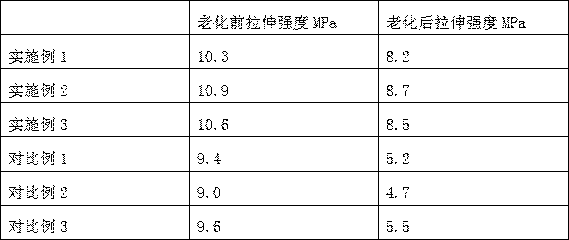

Examples

Embodiment 1

[0020] A dipping solution for aging-resistant clothes hangers, which is made of the following components in parts by weight: PVC resin 80, plasticizer 5, melamine 1, sulfonic acid modified alkyd resin 10, inorganic nano filler 6, defoamer 0.1 , Color masterbatch 0.1; The weight ratio of the PVC resin and the sulfonic acid modified alkyd resin is 8:1.

[0021] Further, the preparation method of the sulfonic acid modified alkyd resin is:

[0022] (1) Under the reaction conditions of 0.3MPa pressure and 60°C temperature, maleic anhydride and saturated high-carbon primary amines were mixed, and reacted under stirring conditions for 2 hours to obtain a reaction intermediate;

[0023] (2) Under the reaction conditions of 0.12MPa pressure and 80°C temperature, the intermediate prepared above was mixed with sulfite, and reacted under stirring conditions for 2 hours to obtain a sulfonic acid modifier;

[0024] (3) Preheat the alkyd resin to 85°C, stir at 1200r / min for 30min, then add ...

Embodiment 2

[0034] A dipping solution for aging-resistant clothes hangers, which is made of the following components in parts by weight: PVC resin 96, plasticizer 8, melamine 3, sulfonic acid modified alkyd resin 12, inorganic nano filler 10, defoamer 0.4 , Color masterbatch 0.3; The weight ratio of the PVC resin and the sulfonic acid modified alkyd resin is 8:1.

[0035] Further, the preparation method of the sulfonic acid modified alkyd resin is:

[0036] (1) Under the reaction conditions of 0.5MPa pressure and 65°C temperature, maleic anhydride and saturated high-carbon primary amines were mixed, and reacted for 3 hours under stirring conditions to obtain a reaction intermediate;

[0037] (2) Under the reaction conditions of 0.15MPa pressure and 90°C temperature, mix the intermediate prepared above with sulfite, and react under stirring conditions for 3 hours to obtain a sulfonic acid modifier;

[0038] (3) Preheat the alkyd resin to 85°C, stir at 1200r / min for 30min, then add 10% of ...

Embodiment 3

[0048] A dipping solution for aging-resistant clothes hangers, which is made of the following components in parts by weight: PVC resin 88, plasticizer 6, melamine 2, sulfonic acid modified alkyd resin 11, inorganic nano fillers 6-10, defoaming Agent 0.3, color masterbatch 0.2; The weight ratio of the PVC resin and the sulfonic acid modified alkyd resin is 8:1.

[0049] Further, the preparation method of the sulfonic acid modified alkyd resin is:

[0050] (1) Under the reaction conditions of 0.4MPa pressure and 62°C temperature, maleic anhydride and saturated high carboprimary amines were mixed, and reacted under stirring conditions for 2.5 hours to obtain a reaction intermediate;

[0051] (2) Under the reaction conditions of 0.13MPa pressure and 85°C temperature, mix the intermediate prepared above with sulfite, and react under stirring conditions for 2.5 hours to obtain a sulfonic acid modifier;

[0052] (3) Preheat the alkyd resin to 85°C, stir at 1200r / min for 30min, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com