Water-based matte pigment transfer printing film and preparation method thereof

A transfer film, water-based technology, applied in the field of printing and hot stamping, can solve the problems of insufficient flexibility of the transfer film, insufficient matte effect on the pattern surface, and many coating materials, and achieve good environmental resources and health advantages, Easy tinting coverage and a matte finish with a fine and plump finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment relates to a water-based matte pigment transfer film and its preparation method, and its preparation process steps are as follows:

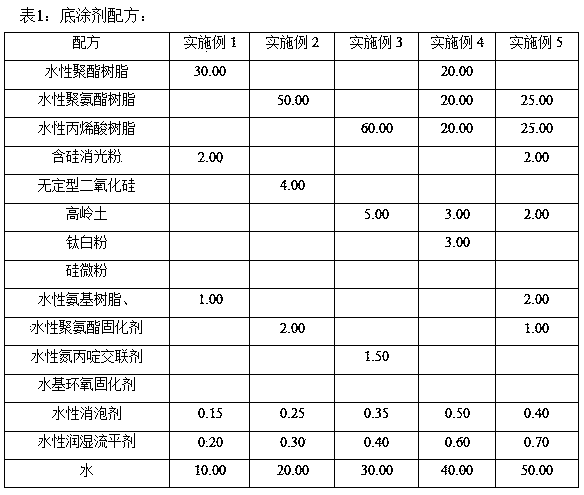

[0044] 1. Preparation of water-based matte primer: the formula is shown in Table 1. After mixing the components in the table, stir with a high-speed mixer at a stirring speed of 800-1200 rpm for 30-60 minutes, filter reserve;

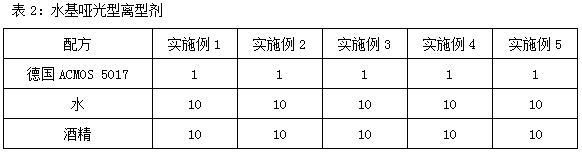

[0045] 2. Preparation of water-based matte release agent: See Table 2 for the dilution ratio. After mixing the materials in the table, stir at a low speed for 10-20 minutes for later use;

[0046] 3. Preparation of water-based colored adhesive layer: See Table 3 for the formula. After mixing the components in the table, stir with a high-speed mixer at a stirring speed of 400-800 rpm for 30-60 minutes, filter and set aside ;

[0047] 4. Coating sequence: First, use an anilox roller coater with 150-200 lines to coat the primer on the PET base film, and dry it with hot air in a drying tunnel at a temp...

Embodiment 2

[0052] The material formula is shown in Tables 1, 2, and 3, and the preparation method is the same as in Example 1.

Embodiment 3

[0054] The material formula is shown in Tables 1, 2, and 3, and the preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com