Environment-friendly electrostatic spraying wax oil as well as preparation method and application thereof

A technology of electrostatic spraying and wood wax oil, applied in the direction of conductive coatings, coatings, wax coatings, etc., can solve the problems of not really achieving raw material safety, environmental protection, reducing costs and drying time, poor wear resistance and film-forming properties , to achieve maximum promotion and application value, save labor and cost, and improve quick-drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

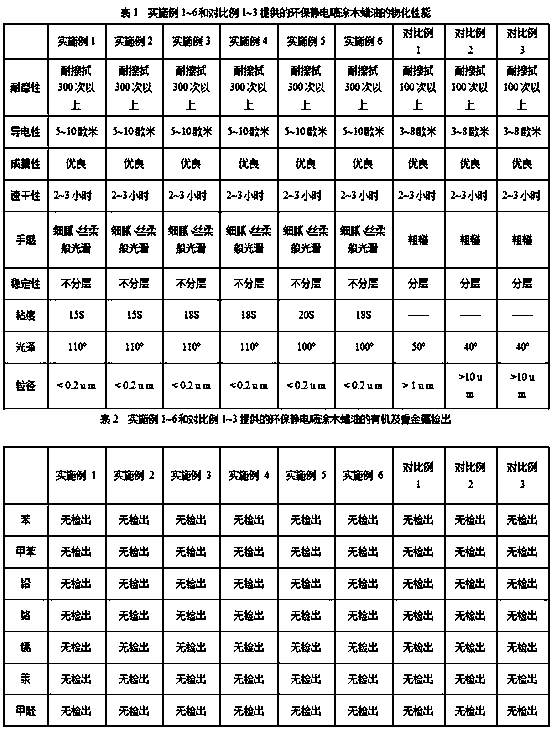

Examples

Embodiment 1

[0037] A kind of environmental protection electrostatic spraying type wood wax oil, described environmental protection electrostatic spraying type wood wax oil is made up of the component of following mass parts:

[0038] 5kg absolute alcohol, 6kg dimethyl carbonate, 10kg PMA, 7kg PCC polyol ester, 15kg celluloid, 10kg maleic acid resin, 20kg blown castor oil, 20kg linseed oil, carnauba 3 kg of wax, 3 kg of beeswax, and 1 kg of electrostatic additive; wherein, the celluloid is composed of the following components by mass percentage: 1 / 2 nitrocellulose 30%, 1 / 4 nitrocellulose 30%, 1 / 8 nitrocellulose Cotton 20%, 1 / 16 nitrocellulose 20%.

[0039] The preparation method of described environmental protection electrostatic spray type wood wax oil is as follows:

[0040] S1: Add celluloid to the environmentally friendly solvent, stir and disperse at 600-800rpm for 15-20 minutes to fully dissolve the celluloid, then add maleic acid resin, and disperse at high speed for 20-25 minutes;...

Embodiment 2

[0044] A kind of environmental protection electrostatic spraying type wood wax oil, described environmental protection electrostatic spraying type wood wax oil is made up of the component of following mass parts:

[0045] 19 kg of environmentally friendly solvent, 20 kg of celluloid, 15 kg of maleic acid resin, 30 kg of blown castor oil, 30 kg of linseed oil, 5 kg of carnauba wax, 5 kg of beeswax, and 2 kg of electrostatic additives.

[0046] The preparation method of the wood wax oil provided in this embodiment is the same as in Example 1.

Embodiment 3

[0048] A kind of environmental protection electrostatic spraying type wood wax oil, described environmental protection electrostatic spraying type wood wax oil is made up of the component of following mass parts:

[0049] Environmentally friendly solvent 37 kg, celluloid 15 kg, maleic acid resin 15 kg, blown castor oil 20 kg, linseed oil 20 kg, carnauba wax 5 kg, beeswax 3 kg, static additive 1 kg.

[0050] The preparation method of the wood wax oil provided in this embodiment is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com