High-chromium high-titanium solvent pellet as well as preparation method and application thereof

A high-chromium and high-titanium technology, applied in the field of ironmaking, can solve the problems of low ironmaking output, achieve the effects of increasing blast furnace output, high compressive strength, and improving the gas permeability of furnace charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

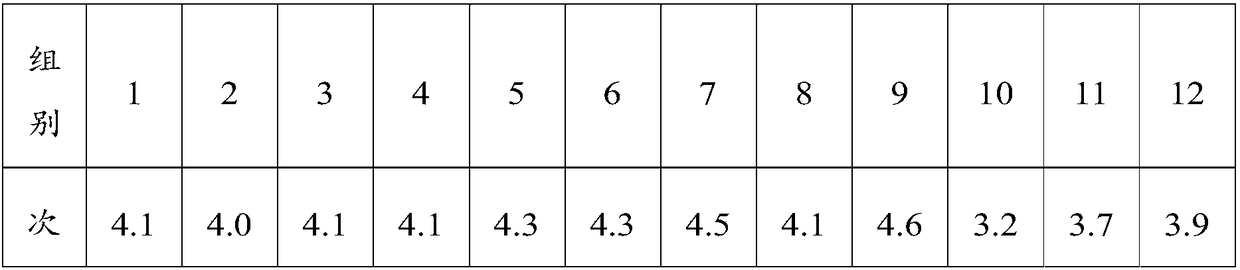

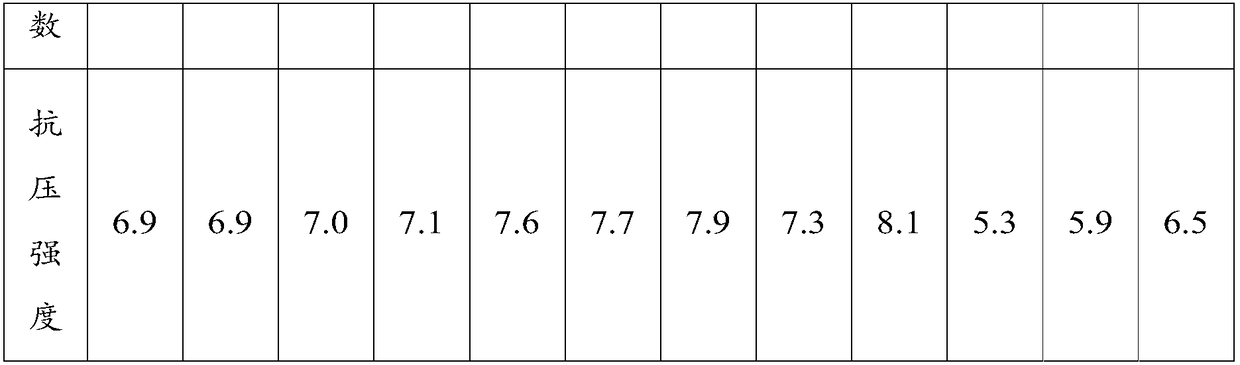

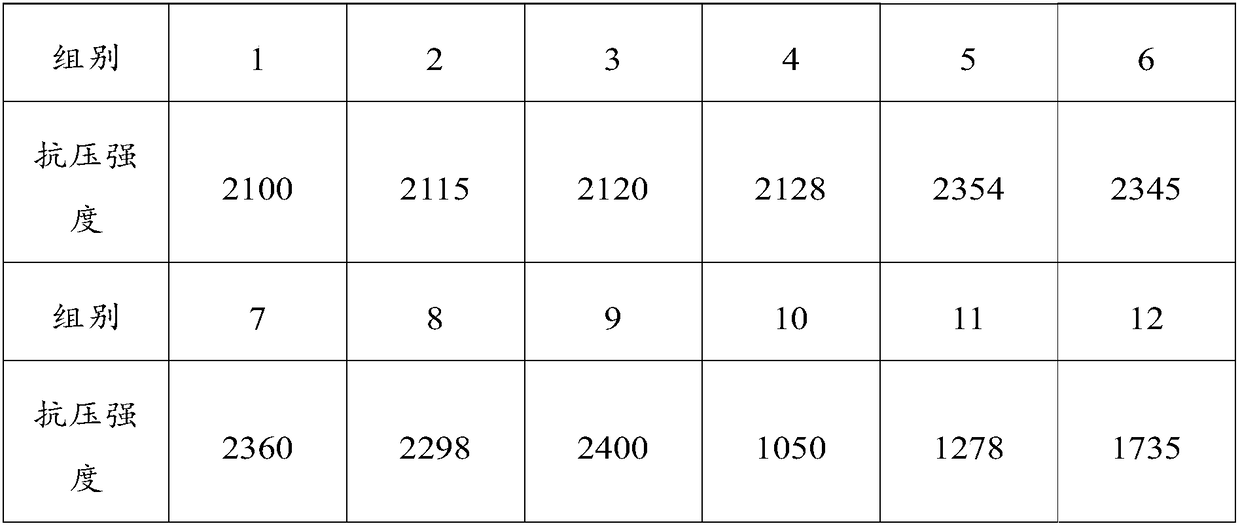

Examples

preparation example Construction

[0018] A preparation method of high chromium and high titanium solvent-based pellets, comprising the steps of:

[0019] S1. Mix the manufacturing raw materials evenly to obtain a mixed pelletizing material. The manufacturing raw materials include 95-98.4.4 parts of high-chromium and high-titanium concentrate, 1.6-3 parts of active lime and 1.5-2.3 parts of bentonite in parts by weight.

[0020] Specifically, high chromium and high titanium concentrate and active lime are used as raw materials for production. First, put the high-chromium and high-titanium concentrate transported back from the mining area to dry in an oven at a drying temperature of 200-300°C for 1.5-2.3 hours, so that the moisture content of the high-chromium and high-titanium concentrate is below 2%. The main purpose of drying the high-chromium and high-titanium concentrate is to avoid the uneven composition and caking phenomenon caused by the direct digestion of the subsequently dried active lime when it is m...

Embodiment 1

[0034] This embodiment provides a method for preparing high-chromium-high-titanium solvent-based pellets and the high-chromium-high-titanium solvent-based pellets prepared by the method.

[0035] A method for preparing high-chromium and high-titanium solvent-based pellets, the preparation steps comprising:

[0036] Put the high-chromium and high-titanium concentrate transported back from the mining area in an oven, and bake it for 1.5 hours at a temperature of 200° C., so that the moisture content of the high-chromium and high-titanium concentrate is below 2%. Then take 160kg of active lime, 9840kg of high-chromium and high-titanium concentrate after drying, and 150kg of bentonite for subsequent use.

[0037] Grind the high-chromium and high-titanium concentrate until the particle size is below 0.109mm and the particles with a particle size below 0.075mm account for 75% of the total weight of the powdery high-chromium and high-titanium concentrate; grind the active lime to the...

Embodiment 2

[0041] This embodiment provides a method for preparing high-chromium-high-titanium solvent-based pellets and the high-chromium-high-titanium solvent-based pellets prepared by the method.

[0042] A method for preparing high-chromium and high-titanium solvent-based pellets, the preparation steps comprising:

[0043] The high-chromium and high-titanium concentrate transported back from the mining area is placed in an oven, and baked at a temperature of 300°C for 2.5 hours, so that the moisture content of the high-chromium and high-titanium concentrate is below 2%. Then take 180kg of active lime, 9770kg of dried high-chromium and high-titanium concentrate and 150kg of bentonite for subsequent use.

[0044]Grind the high-chromium and high-titanium concentrate until the particle size is below 0.109mm and the particles with a particle size below 0.075mm account for 85% of the total weight of the powdery high-chromium and high-titanium concentrate; grind the active lime to the partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com