Method for efficiently preparing pure CoSb3-based medium-temperature thermoelectric material

A technology of thermoelectric materials and electric materials, which is applied in the field of efficient preparation of pure CoSb3-based medium-temperature thermoelectric materials, can solve the problems of environmental pollution and unpredictable preparation results, and achieves the effects of simple process, low cost and good application prospect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for efficiently preparing a pure CoSb3-based medium-temperature thermoelectric material. The CoSb3-based medium-temperature thermoelectric material refers to a CoSb3-based material that can be filled or doped with other elements to form a dimensionless thermoelectric with a high figure of merit A medium-temperature thermoelectric material, the preparation method comprising the steps of:

[0036] Step 1: According to the phase diagram of the Co-Sb alloy, select the appropriate ingredients for batching.

[0037] It can be seen from the phase diagram of Co-Sb alloy that there are two peritectic reactions and one eutectic reaction in Co-Sb alloy. When the alloy composition is in the range of 86.1-92.7wt% Sb, 92.7-94.9wt% Sb and 94.9-99.6wt% Sb, two peritectic reactions CoSb+L→CoSb2(936 ℃), CoSb2+L→CoSb3 (874℃), a peritectic reaction CoSb2+L→CoSb3 (874℃), and a eutectic reaction L→CoSb3+Sb (630℃). Therefore, different results can be obtained by choosing different ...

Embodiment 1

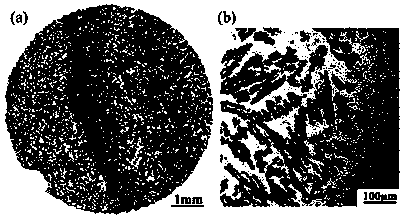

[0042] Embodiment 1: select the alloy composition Co-87.9wt%Sb with Sb content between 86.1-92.7wt%, by figure 1 It can be seen from the phase diagram of Co-Sb alloy that under this composition, the as-cast structure of the alloy will consist of CoSb, CoSb2, CoSb3 and Sb. Composition of as-cast microstructure under light microscope ( figure 2 ) are consistent with the results obtained by phase diagram analysis.

[0043] The specific preparation is as follows:

[0044] First, mix Co and Sb evenly according to the selected alloy composition. Considering that the melting points of Co and Sb are quite different, 2% more Sb is added during the configuration process to compensate for the volatilization of Sb. Then melt the uniformly mixed components in a high vacuum directional solidification furnace to reach the required temperature (determine the temperature according to the Co-Sb alloy phase diagram) and keep it warm for 30 minutes and then cool to obtain an ingot. In order to...

Embodiment 2

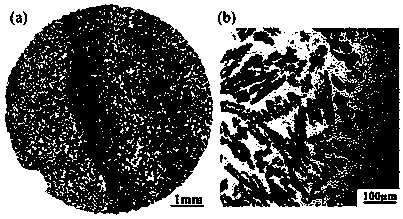

[0047] Embodiment 2: select the alloy composition Co-93wt%Sb with Sb content between 92.7-94.9wt%, by figure 1 It can be seen from the phase diagram of Co-Sb alloy that under this composition, the as-cast structure of the alloy will consist of CoSb2, CoSb3 and Sb. Composition of as-cast microstructure under light microscope ( Figure 4 ) are consistent with the results obtained by phase diagram analysis.

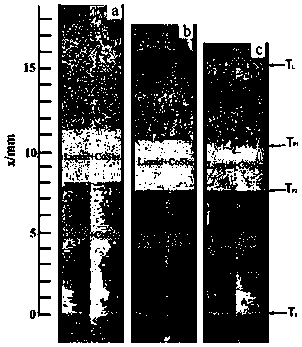

[0048] The specific preparation process is roughly the same as in Example 1, except that the holding temperature is 1050°C, and in the last step, according to Figure 5 According to the longitudinal section structure diagram, it can be found that according to the TGZM effect, the longitudinal section structure of the mushy zone is composed of L+CoSb2 phase and L+CoSb3 phase, and there is a clear boundary between the two phases. Finally, the corresponding CoSb3 tissue can be intercepted as needed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com