High-surface-quality aluminum coating steel plate and production method thereof

A production method, aluminum coating technology, applied in the direction of coating, hot-dip coating process, metal material coating process, etc., can solve the problems of reduced corrosion resistance, no feasibility, increased cost, etc., and achieve the effect of high surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

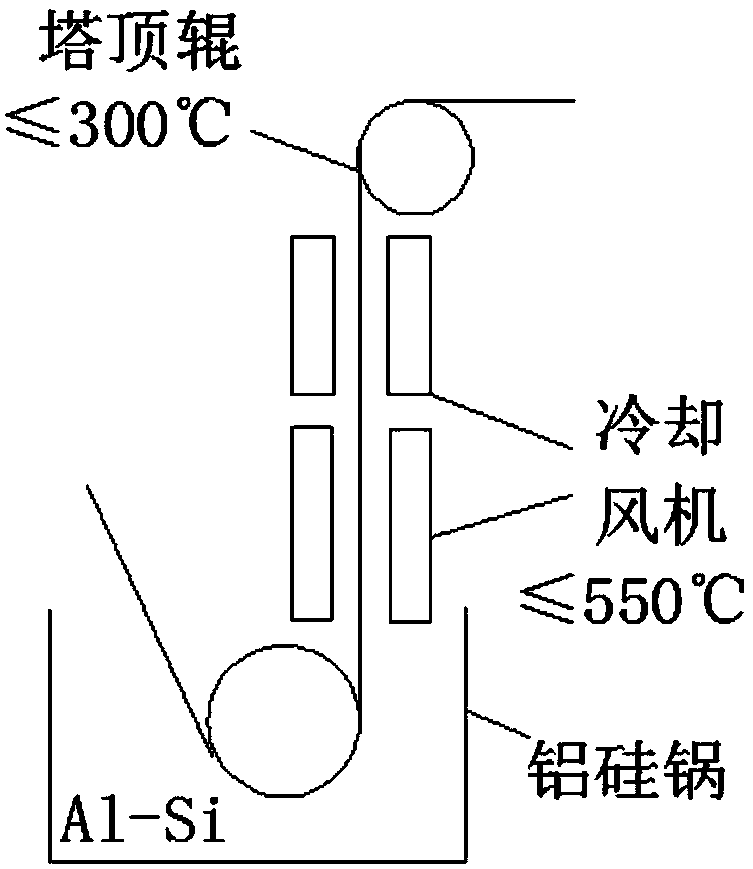

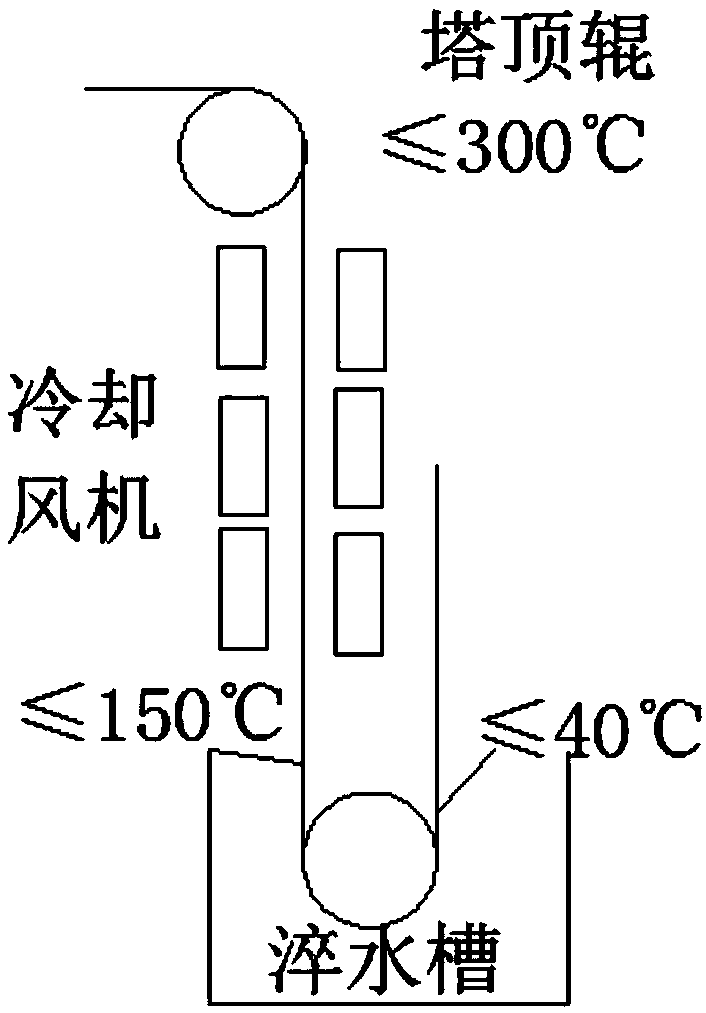

Method used

Image

Examples

Embodiment 1

[0067] An aluminum-coated steel plate with high surface quality, including a substrate and a coating. Example 1 takes ordinary low-carbon steel as an example. The substrate contains the following chemical components in mass percentages: C: 0.090%, Si: 0.020%, Mn: 0.30%, P: 0.013%, S: 0.008%, Als: 0.048%, N: 0.0034%, Nb: 0.008%, Ti: 0.008%, and the rest are Fe and unavoidable impurity elements.

[0068] The coating contains the following chemical components in mass percentage: 7.4% Si, 1.1% Fe, 0.05% La, 0.15% Ti, the balance being Al and a small amount of unavoidable impurities.

[0069] The production method of the above-mentioned high surface quality aluminum-coated steel plate comprises the following steps:

[0070] 1) Pretreatment of molten iron: it is required to remove slag before and after.

[0071] 2) Converter smelting: no pig iron and slag steel are added; self-circulating scrap steel is used to tap steel to strengthen converter dephosphorization and slag retaining ...

Embodiment 2

[0088] An aluminum-coated steel plate with high surface quality, including a substrate and a coating. Example 1 takes ordinary low-carbon steel as an example. The substrate contains the following chemical components in mass percentages: C: 0.21%, Si: 0.26%, Mn: 1.24%, P: 0.013%, S: 0.002%, Als: 0.035%, Cr: 0.10%, Nb: 0.001%, N: 0.0010%, Ti: 0.01%, B: 0.002%, the rest is Fe and unavoidable impurities element.

[0089] The coating contains the following chemical components in mass percentage: 7.4% Si, 1.1% Fe, 0.05% La, 0.15% Ti, the balance being Al and a small amount of unavoidable impurities.

[0090] The production method of the above-mentioned high surface quality aluminum-coated steel plate comprises the following steps:

[0091] 1) Pretreatment of molten iron: it is required to remove slag before and after.

[0092] 2) Converter smelting: no pig iron and slag steel are added; self-circulating scrap steel is used to tap steel to strengthen converter dephosphorization and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com