Puncture-resistant anti-aging PVC (polyvinyl chloride) inflatable boat material

An anti-aging, inflatable boat technology, used in textiles and papermaking, can solve problems such as poor puncture resistance, inability to protect people, drowning, etc., to enhance migration resistance, increase flame retardant and degradable ability, and mechanical properties. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

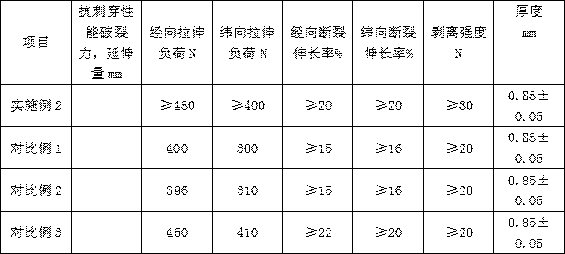

Examples

Embodiment 1

[0024] A clean and ecologically degradable PVC decorative artificial leather is made of the following raw materials in parts by weight: 100 parts of PVC resin powder, 30 parts of vinyl acetate resin, 38 parts of DOTP, 20 parts of modified PBO chopped fibers, 1 part of foaming agent, 20 parts of epoxy soybean oil, 20 parts of organically modified clay, 1 part of lubricant, 1 part of silicone masterbatch, 1 part of stabilizer, and 1 part of pigment.

[0025] A puncture-resistant anti-aging PVC inflatable boat material, which comprises the following steps:

[0026] (1) Put the weighed PVC resin powder, vinyl chloride resin, modified PBO chopped fiber, lubricant, silicone masterbatch, and stabilizer into a high-speed kneader, then add epoxy soybean oil, and stir for 10 minutes , then add DOTP, stir for another 10 minutes, add pigment, stir for another 3 minutes, add organically modified clay and foaming agent, and stir for 5 minutes. When the mixing temperature reaches 100°C, whe...

Embodiment 2

[0037] A clean and ecologically degradable PVC decorative artificial leather is made of the following raw materials in parts by weight: 100 parts of PVC resin powder, 30 parts of vinyl acetate resin, 36 parts of DOTP, 15 parts of modified PBO chopped fibers, 1 part of foaming agent, 24 parts of epoxy soybean oil, 22 parts of organically modified clay, 1 part of lubricant, 1 part of silicone masterbatch, 1 part of stabilizer, and 1 part of pigment.

[0038] A puncture-resistant anti-aging PVC inflatable boat material, which comprises the following steps:

[0039] (1) Put the weighed PVC resin powder, vinyl chloride resin, modified PBO chopped fiber, lubricant, silicone masterbatch, and stabilizer into a high-speed kneader, then add epoxy soybean oil, and stir for 5 ~10min, then add DOTP, stir for another 10min, add lubricant, pigment, stir for another 3min, add organically modified clay and foaming agent, and stir for 5min. When the mixing temperature reaches 90~100℃, when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com