Sound insulation and noise reduction wall body of sound elimination and noise reduction movable operation room for machining

A mobile operation and machining technology, applied in the direction of sound insulation, insulation layer, floor, etc., can solve the problems such as the inability to increase the absorption time of the sound-absorbing device, the single method of sound insulation and noise reduction, and slowing down the speed of noise transmission. The effect of improving the absorption effect, improving the noise absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

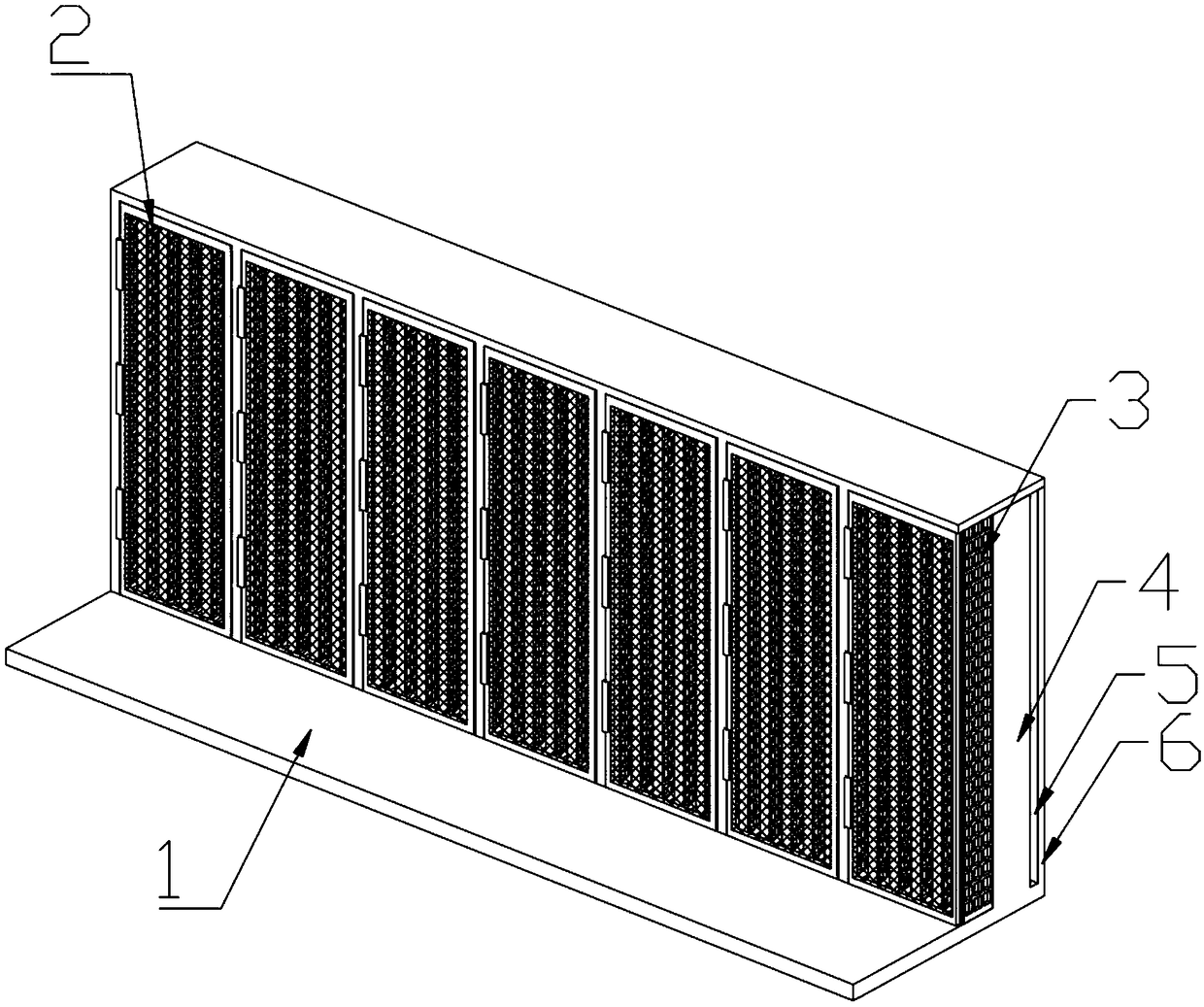

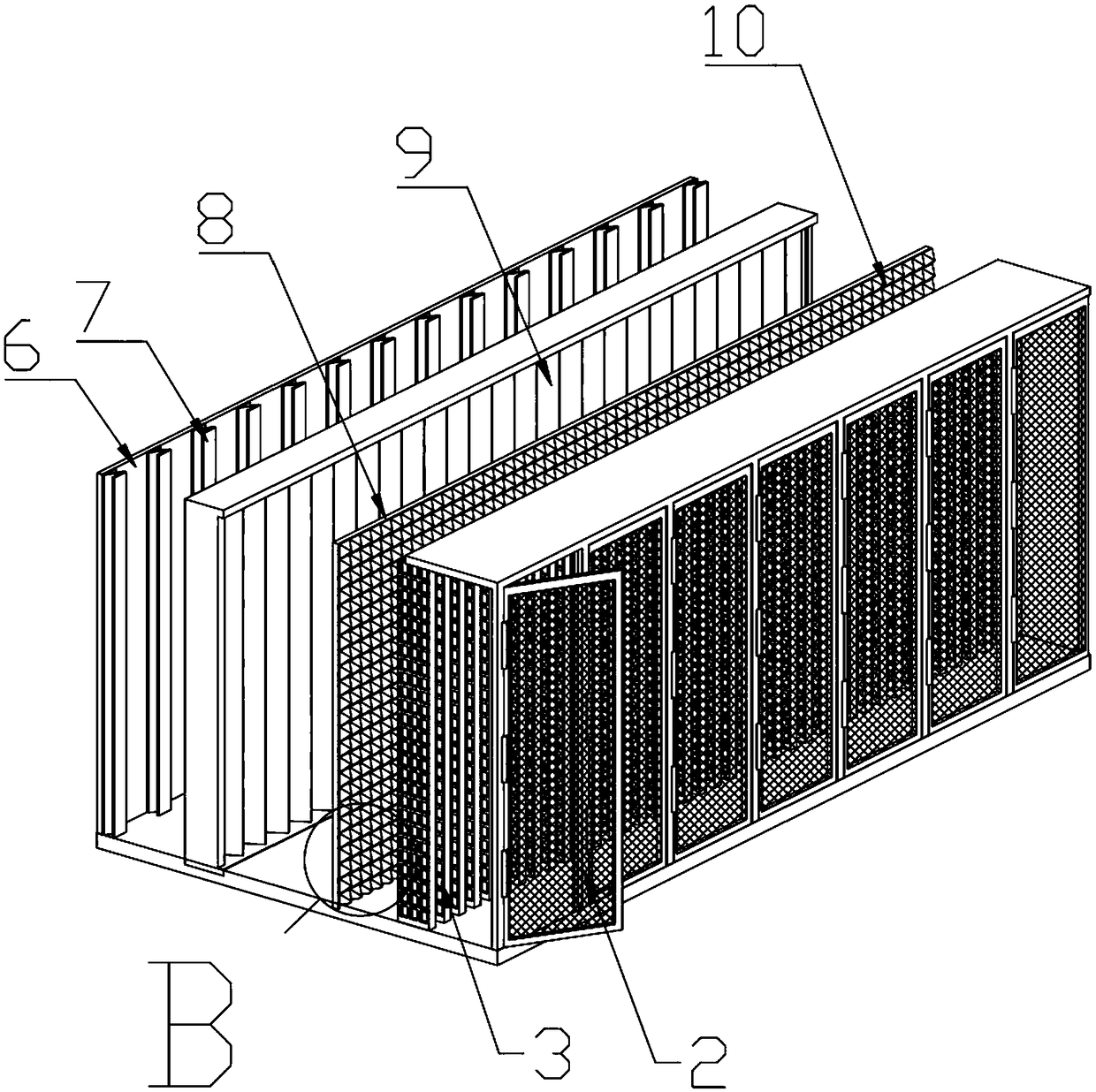

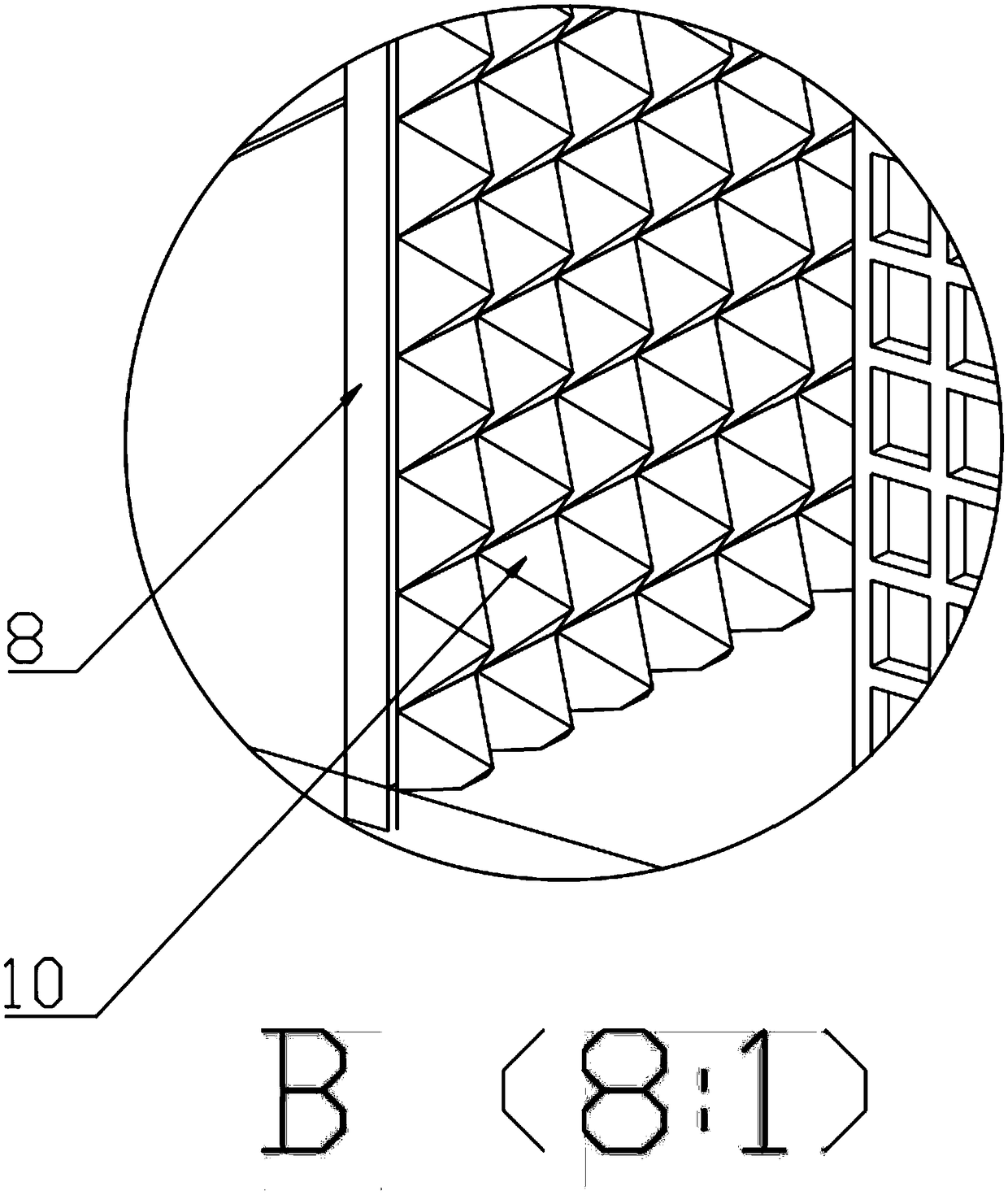

[0040] as attached figure 1 to attach Figure 8 Shown:

[0041] The present invention provides a sound-insulating and noise-reducing wall of a noise-absorbing and noise-reducing mobile operation room for mechanical processing, which includes: a bottom surface structure 1, a dust-proof net door 2, a suction groove plate 3, a sound-absorbing groove 301, a sound-absorbing water tank 4, and a buffer and sound-proof cavity 5. External wall 6, shock-absorbing keel 7, sound-absorbing cotton wall 8, sound-absorbing panel 9, sound-absorbing cotton 10 and dust-proof net door fixing frame 11; the dust-proof net door fixing frame 11 is fixed on the upper side of the bottom structure 1 The dust-proof net door 2 is fixedly installed on the dust-proof net door fixing frame 11 by rotating the hinge; the sound-absorbing cotton 10 is pasted and fixed on one side of the sound-absorbing cotton wall 8; the suction groove plate 3 It is fixedly installed on the sound-absorbing cotton wall 8 pasted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com