Filling material feeding device and system

A technology of feeding device and filling material, applied in the direction of filling material, safety device, packaging, etc., can solve the problems of low measurement accuracy, poor feeding, sound wave interference, etc., and achieve the effect of high measurement accuracy and smooth feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

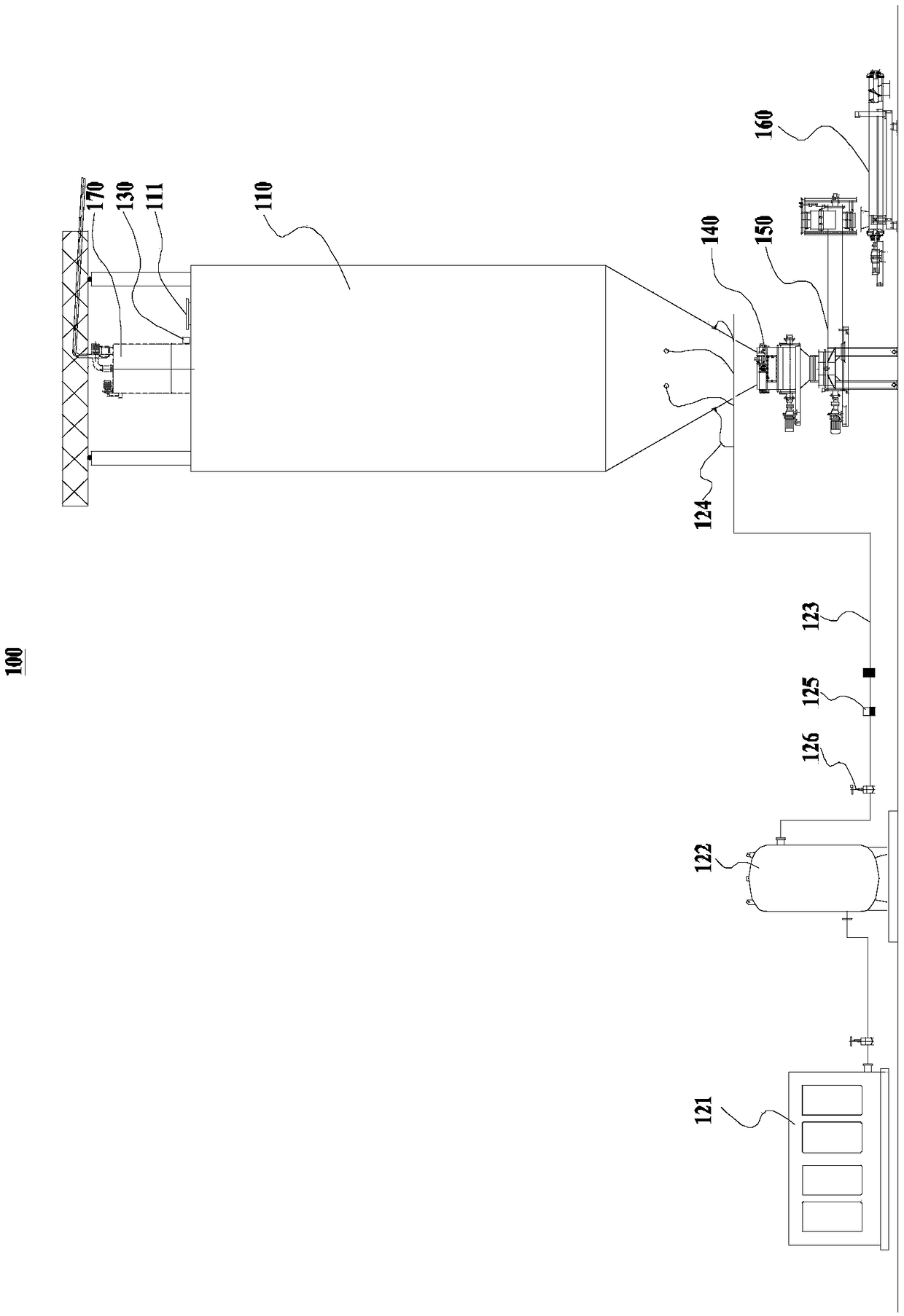

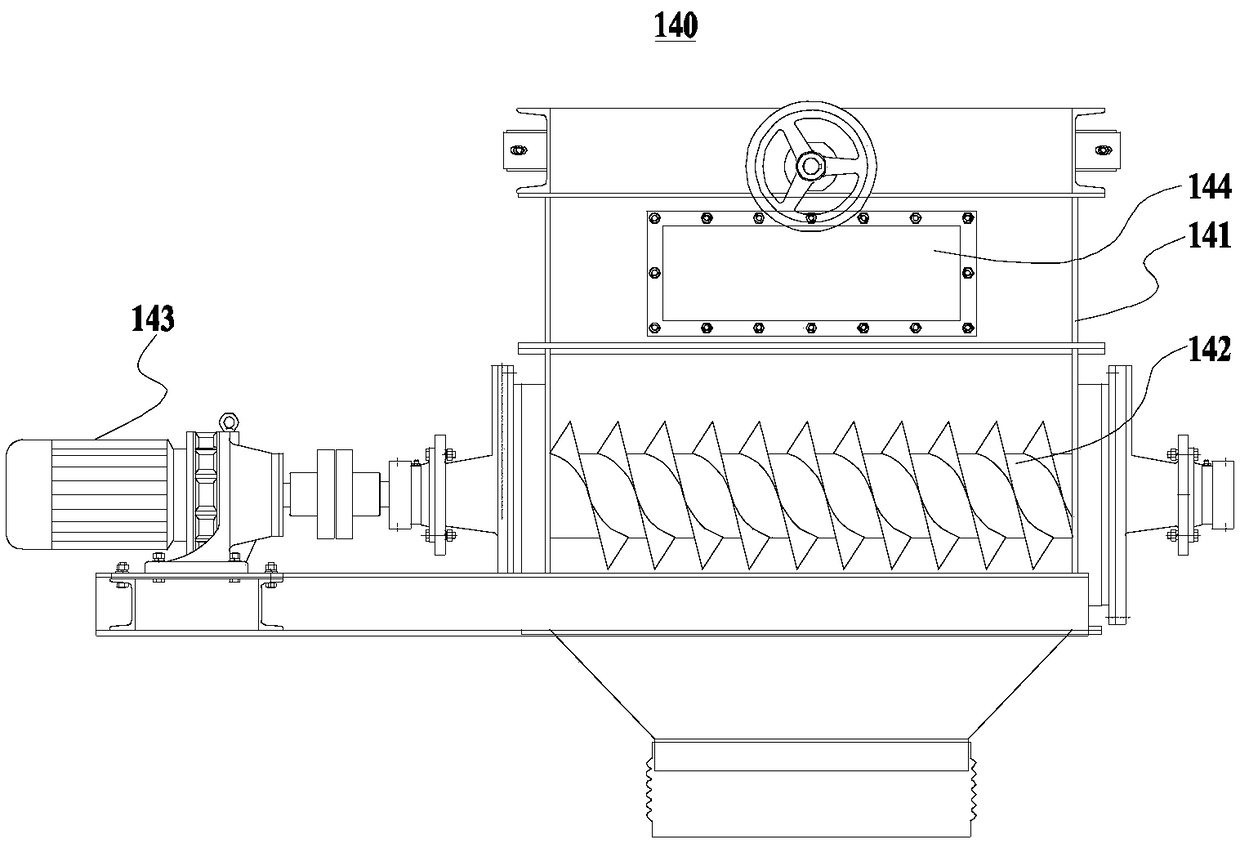

[0032] Please refer to figure 1 As shown, the present embodiment provides a filler feeding device 100, which includes a silo 110, and an arch breaking device for breaking the arch inside the silo 110. A radar level gauge 130 is installed on the top of the silo 110. The outlet of the bin 110 is equipped with a flow stabilization device 140, the outlet of the flow stabilization device 140 is connected with a micropowder scale 150, and a screw feeder 160 is arranged below the outlet of the micropowder scale 150. When cement is used as filling material, what is stacked in the silo 110 is cement, and the silo 110 at this time is the cement silo; Storehouse 110 is exactly glue solid powder storehouse. Usually, the main body of the silo 110 (cement silo or cement powder silo) is cylindrical, and the bottom is a cone, which is in an inverted cone shape; the feed port of the silo 110 is located at the top, and the discharge port is located at the end of the cone. cutting edge.

[00...

no. 2 example

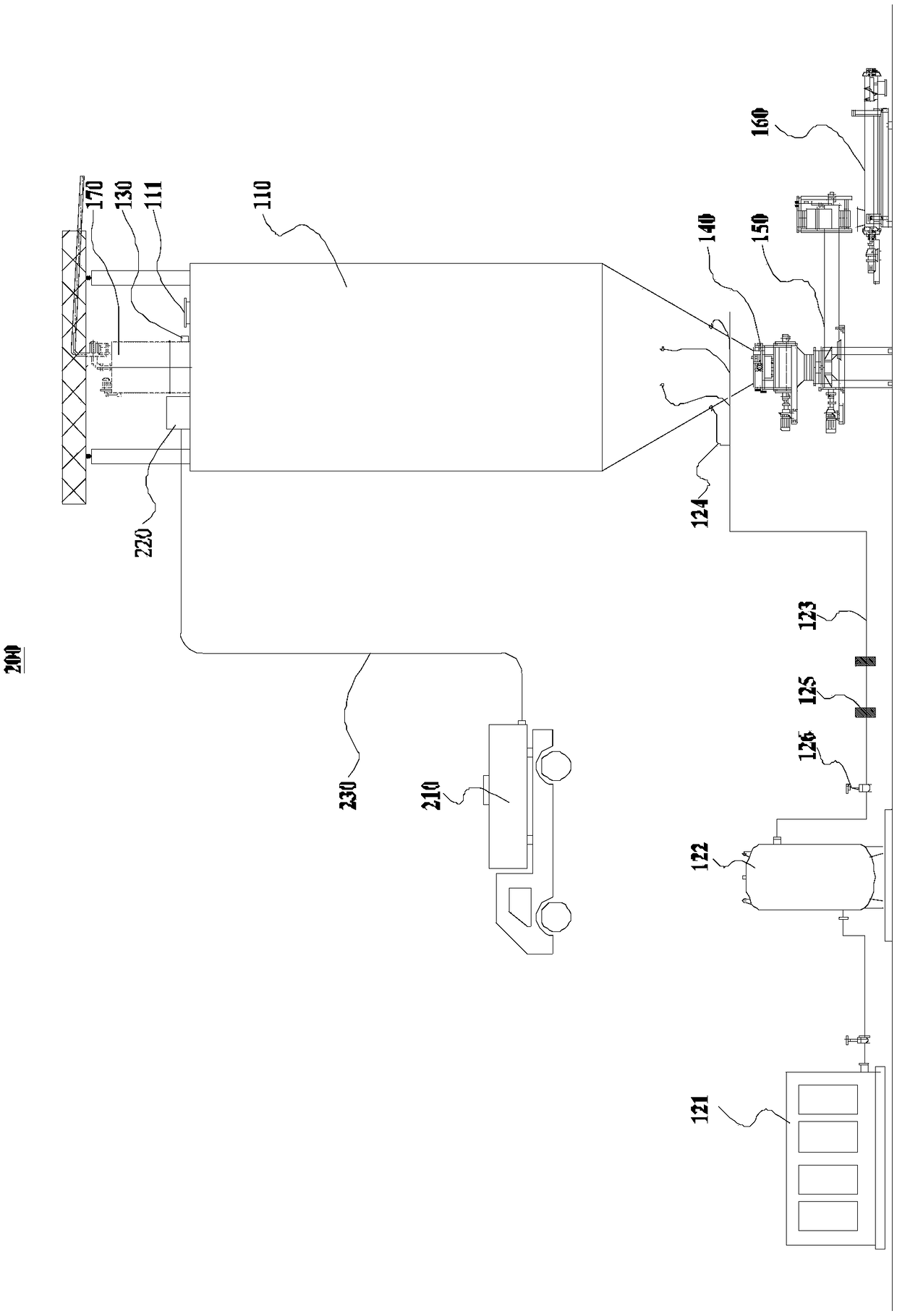

[0044] Please refer to image 3 As shown, the present embodiment provides a filling material feeding system 200, which includes a cement tank 210, a filter box 220 and the filling material feeding device 100 of the first embodiment, and the cement tank 210 is generally transported by a cement tank 210 truck to On site, the cement tank 210 communicates with the feed port of the filter box 220 through the soot blowing pipe 230 , and the discharge port of the filter box 220 communicates with the feed port of the silo 110 . The cement tank 210 is used to replenish the filling material to the silo 110, and then realize high-precision uniform feeding through the filling material feeding device 100. The filling material in the cement tank 210 first enters the filter box 220 for filtering treatment, and then enters the feed bin 110 from the filter box 220, which can ensure that the bulk materials or impurities in the filling material cannot enter the feed bin 110 (cement bin or glue s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com