Rear-end-ignition pulse detonation combustion engine

A technology of pulse detonation and engine system, applied in the direction of machine/engine, gas turbine device, mechanical equipment, etc., can solve the problems of low ignition energy, long DDT pipe section, system complexity, etc., to reduce fluctuation and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

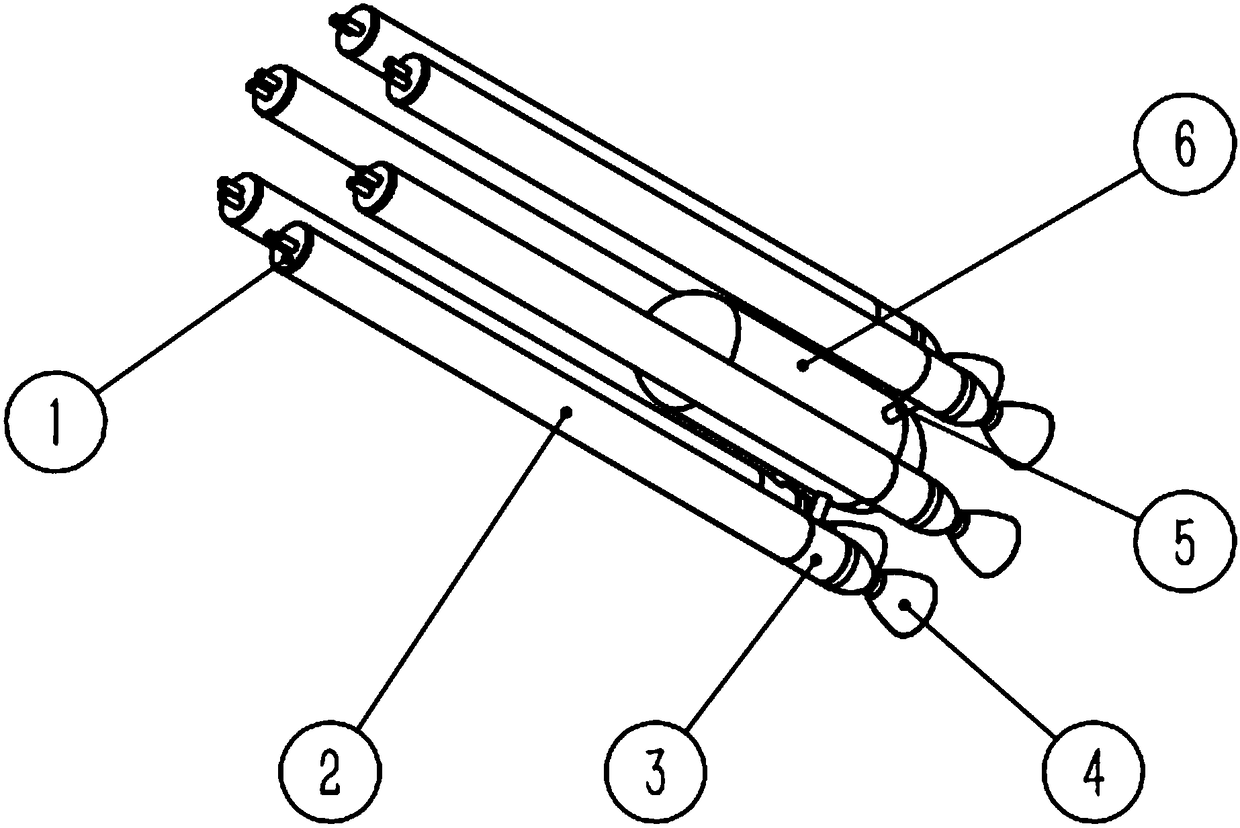

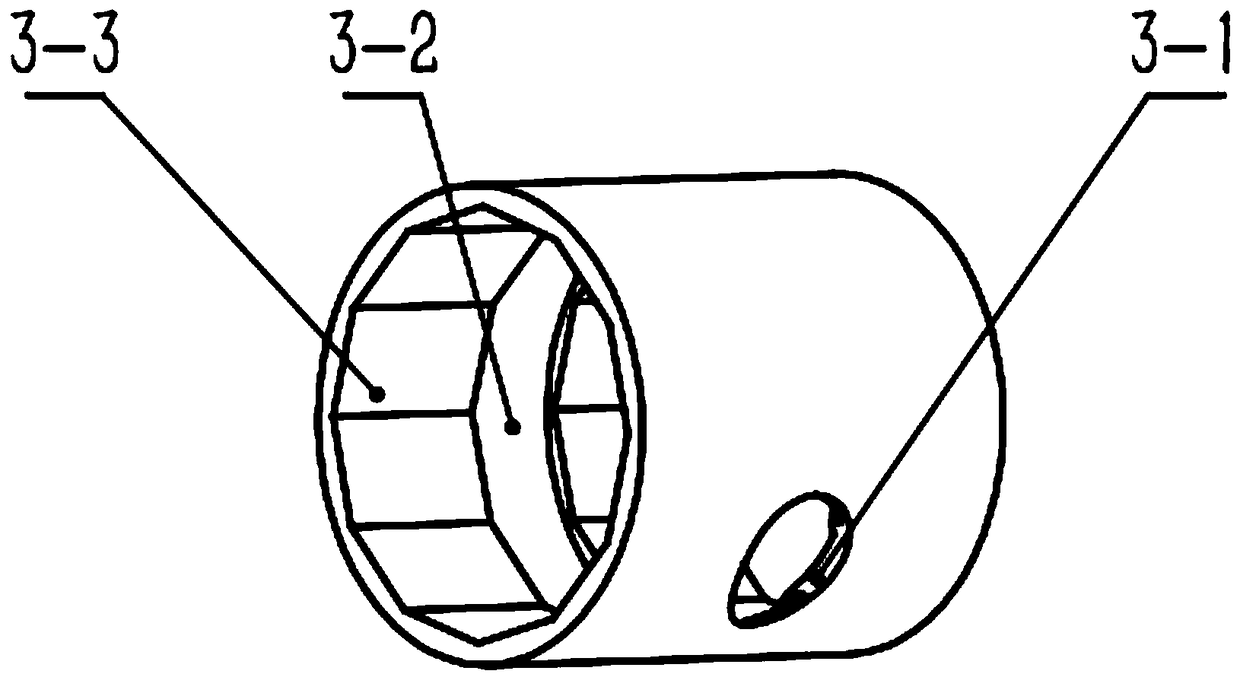

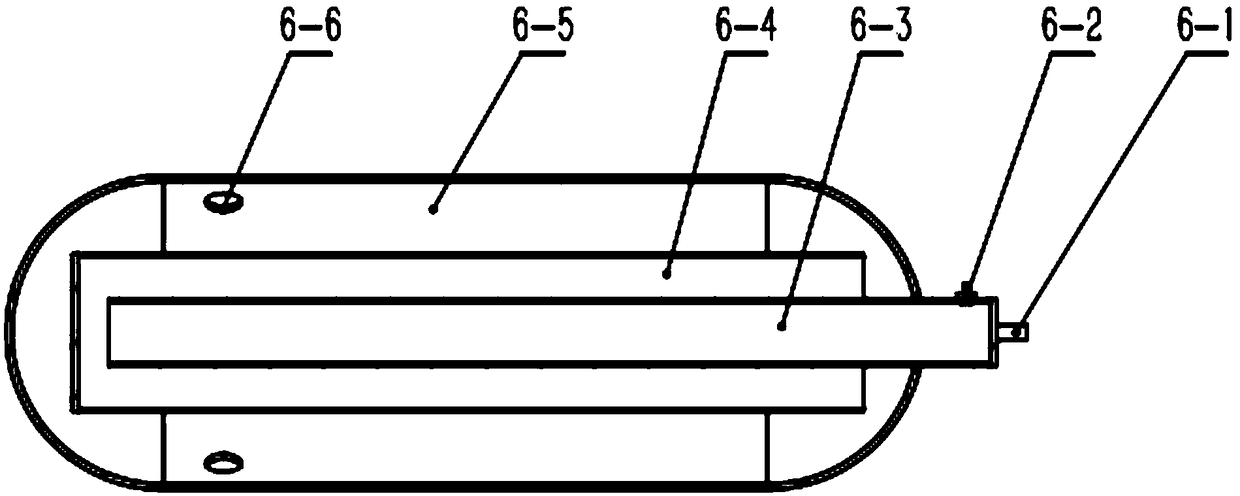

[0019] see Figure 1-Figure 5 , a multi-tube parallel pulse detonation engine system with large heat flow ignition at the rear end, each component is in accordance with figure 1 with Figure 4 Assembled as shown, the whole system includes explosive gas mixture and isolation gas supply device, ignition and detonation device, and multiple parallel detonation chamber systems. The fuel supply system is composed of oxidant storage tank, isolation gas storage tank, fuel storage tank, explosive mixture splitter, isolation gas splitter, high-frequency solenoid valve at the entrance of detonation chamber, and the connecting pipelines and valve systems of these components. In addition, it also includes a corresponding valve switch phase control system. Each detonation chamber system includes a detonation chamber inlet 1, a detonation chamber 2, an igniter 3, a nozzle 4 and a jet propagation pipe 5; The most downstream of the airflow of the shock chamber 2; the igniter 3 is located be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com