Torsion shaft surface rolling and strengthening machine tool hydraulic oil supply system

A technology of oil supply system and torque shaft, which is applied in the hydraulic field, can solve the problems of reducing heat generation and cumbersome maintenance of the hydraulic system, and achieve the effect of realizing energy and protecting from damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

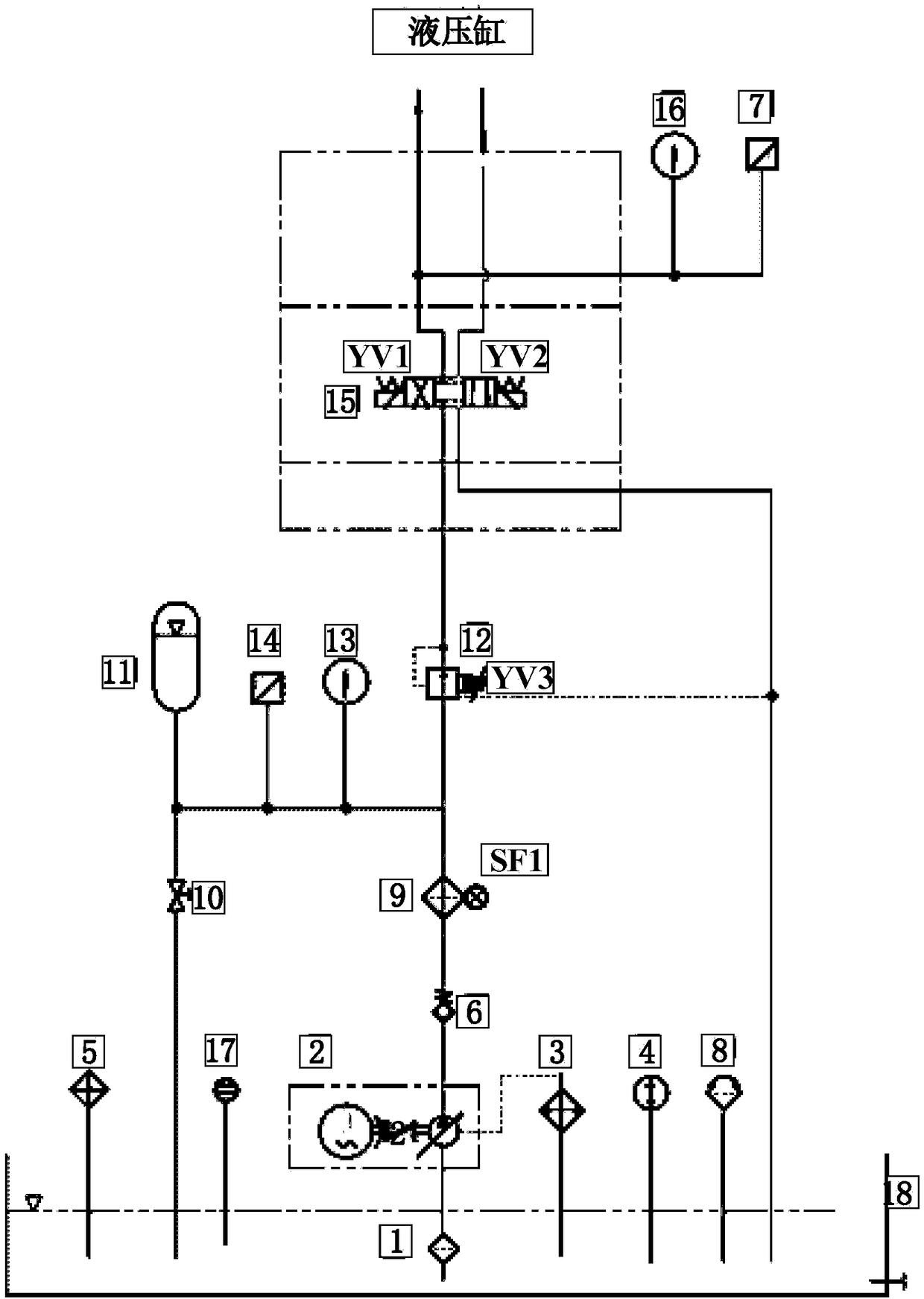

[0024] Such as figure 1 As shown, the hydraulic oil supply system of the torsion shaft surface rolling enhanced machine tool includes a control unit (not shown in the figure), a coarse filter (1), a motor pump assembly (2), an air cooler (3), a temperature variable transmitter (4), heater (5), one-way valve (6), pressure sensor (7), air filter (8), fine filter (9), stop valve (10), accumulator ( 11), electro-hydraulic proportional pressure relief valve (12), pressure gauge (13), pressure relay (14), three-position four-way electromagnetic reversing valve (15), pressure digital display gauge (16), liquid level relay (17) and oil tank (18), the connection relation between above-mentioned each element is:

[0025] Motor pump assembly (2) The inlet of the pump is connected to the coarse filter (1), and the outlet of the pump is connected to the check valve (6), the fine filter (9), the electro-hydraulic proportional decompression and overflow valve (12), and the three-position F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com