Optical wave plate with low wavelength sensitivity, large size and true zero order as well as preparation method and application of optical wave plate

A true zero-order, sensitive technology, applied in optics, optical components, lasers, etc., can solve the problems of few application occasions, small cutting angle range, and narrow wavelength bandwidth, and achieve wide application range, large cutting angle range, and wavelength The effect of bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

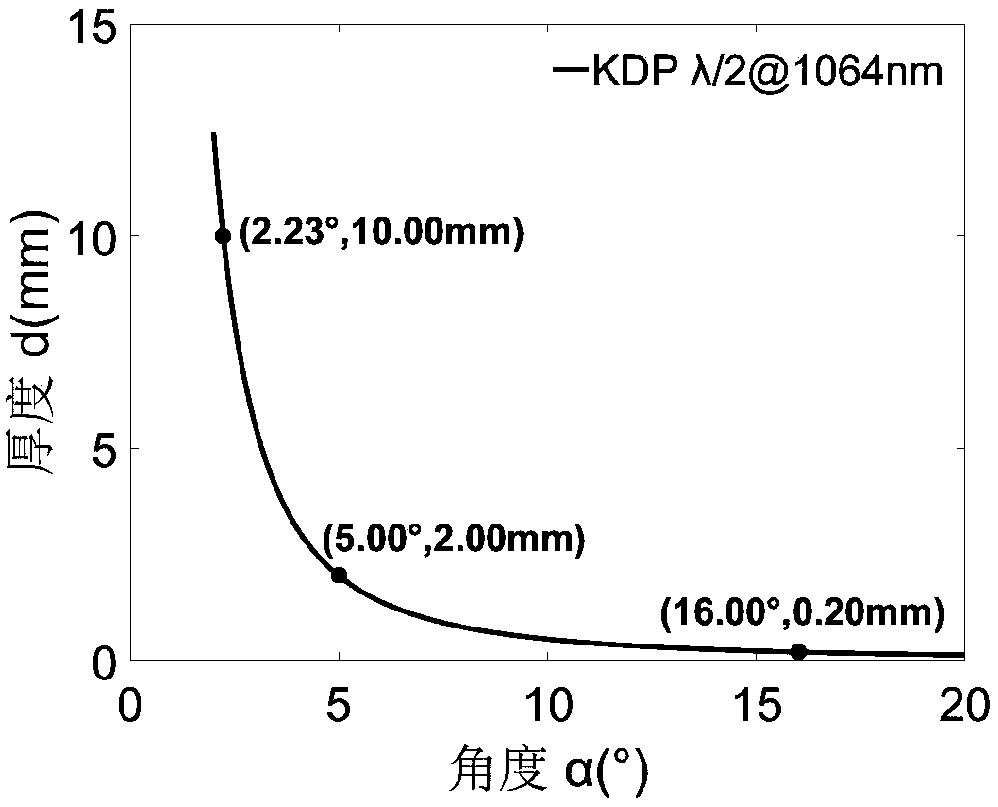

[0066] A large-size true zero-order optical wave plate with low wavelength sensitivity. The type of the wave plate is a half-wave plate; the material of the wave plate is KDP crystal; the aperture is 1cm, the thickness is 200μm, and the 1064nm true zero-order KDP half-wave Chip device, its cut angle α is 16.00°, such as figure 1 shown.

Embodiment 2

[0068] A large-size true zero-order optical wave plate with low wavelength sensitivity, the type of the wave plate is a half-wave plate; the material of the wave plate is KDP crystal; the diameter is 10cm, the thickness is 2mm, 1064nm true zero-order KDP half-wave Chip device, the cut angle α is 5.00°, such as figure 1 shown.

[0069] The experimental device for detecting the wavelength sensitivity of waveplates by polarization interferometry is as follows: Figure 9 shown. The polarizer and analyzer are parallel to each other, and the KDP or ADP half-wave plate is placed in the middle. The direction of the optical axis of the wave plate forms an included angle of 45° with the direction of transmission of the polarizer or analyzer. The light output intensity of the entire test system depends on the polarization state behind the wave plate. The change of wavelength affects the phase retardation of the wave plate, and then changes the polarization state of the output light a...

Embodiment 3

[0072] A large-size true zero-order optical wave plate with low wavelength sensitivity. The type of the wave plate is a half-wave plate; the material of the wave plate is KDP crystal; the aperture is 50cm, the thickness is 1cm, and the 1064nm true zero-order KDP half-wave Chip device, the cut angle α is 2.23°, such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com