Preparation method of high performance oxide coated nano-SnO2 negative electrode material

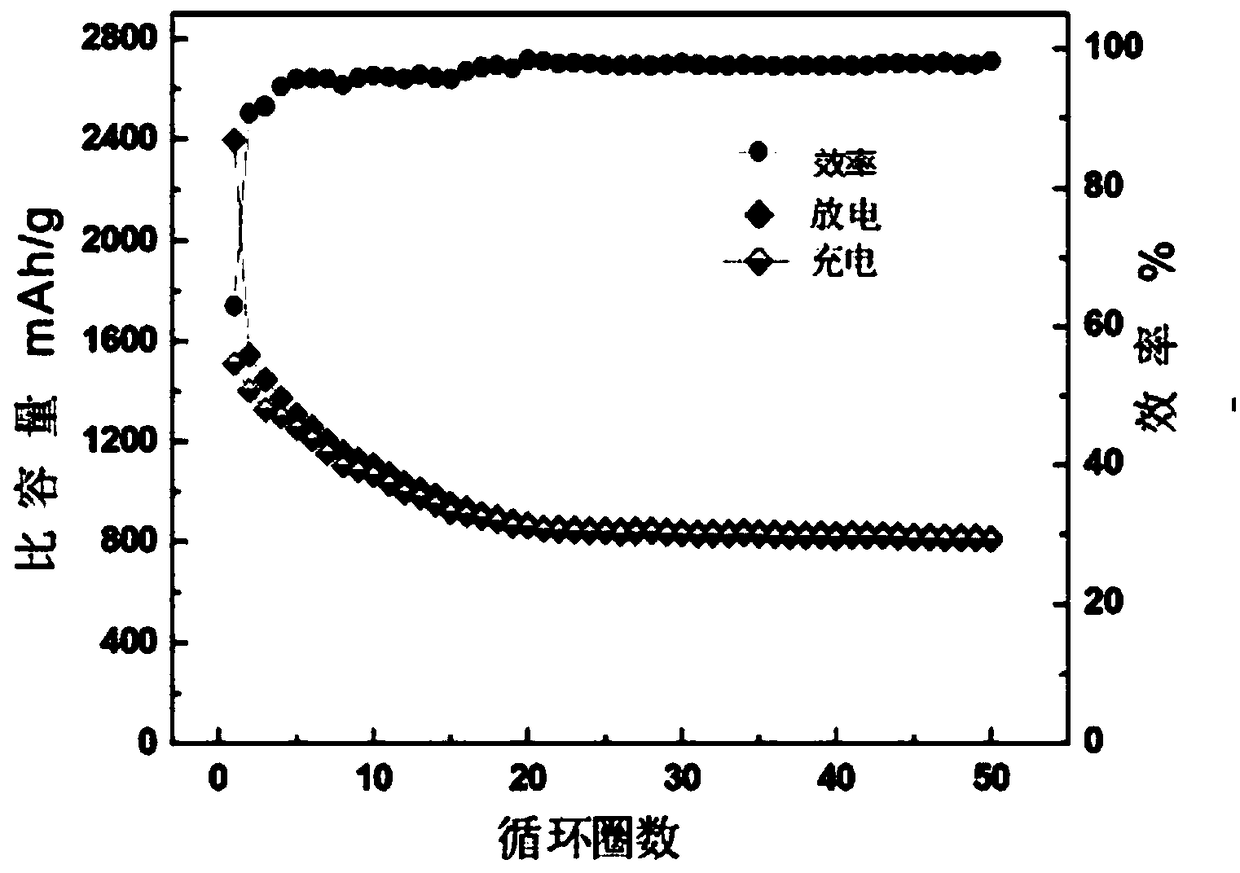

A negative electrode material, oxide technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of low expansion mechanical properties of tin-based materials, affecting the insertion and extraction of lithium ions, and affecting the tin-based materials. Material specific capacity and other issues, to achieve the effect of simple preparation method, inhibition of expansion, and good charge-discharge cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

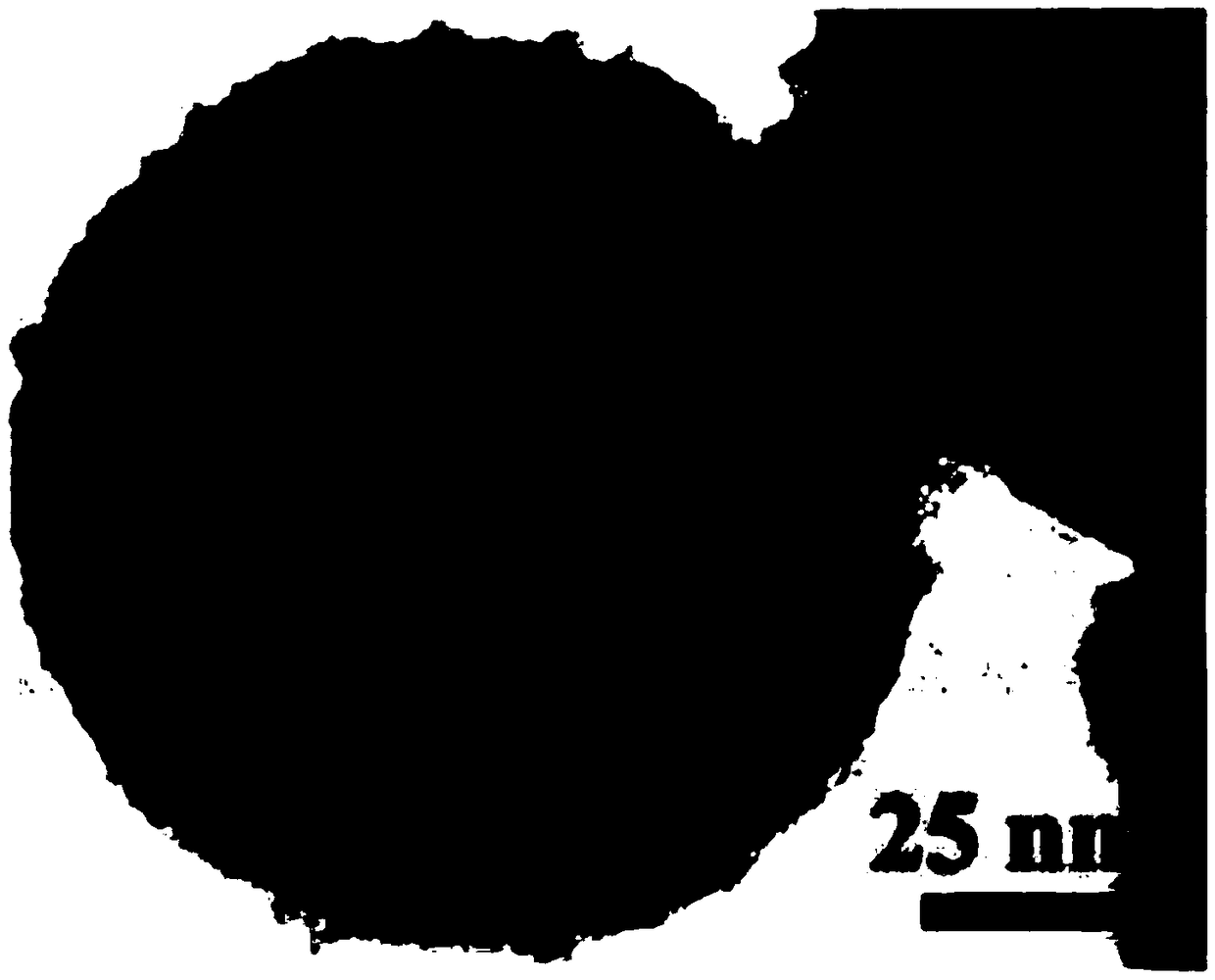

[0034] A high-performance oxide-coated nano-SnO 2 The preparation method of negative electrode material, comprises the following steps:

[0035] S1 spherical nano SnO 2 Put the particles in a vacuum oven and bake at 80°C for 12 hours, take them out and put them in a brown reagent bottle to seal for later use;

[0036] S2, using the atomic layer deposition method, the dry spherical nano-SnO 2 The particles are put into the atomic layer deposition chamber, the chamber temperature is heated to 120°C, and ethylene glycol is used as the pulse precursor for passivation. The passivation time is 65s, and then purged with carrier gas;

[0037] S3. Using the atomic layer deposition method, the spherical nano-SnO loaded with passivation 2 The atomic layer deposition chamber of the particles was heated to 250 °C, using titanium pentaethoxide as the precursor A, and deionized water as the precursor B, the passivated spherical nano-SnO 2 The particles are subjected to cyclic deposition ...

Embodiment 2

[0040] A high-performance oxide-coated nano-SnO 2 The preparation method of negative electrode material, comprises the steps:

[0041] S1. Spherical nano SnO 2 Put the particles into a vacuum oven and bake at 100°C for 10 hours, take them out and put them into a brown reagent bottle to seal for later use;

[0042] S2, using the atomic layer deposition method, the dry spherical nano-SnO 2 The particles are put into the atomic layer deposition chamber, the temperature of the chamber is heated to 150°C, and ethylene glycol is used as the pulse precursor for passivation. The passivation time is 35s, and then purged with carrier gas;

[0043] S3. Using the atomic layer deposition method, the spherical nano-SnO loaded with passivation 2The atomic layer deposition chamber of the particles was heated to 350 °C, using titanium pentaethoxide as the precursor A and deionized water as the precursor B, the passivated spherical nano-SnO 2 The particles are subjected to cyclic deposition...

Embodiment 3

[0045] A high-performance oxide-coated nano-SnO 2 The preparation method of negative electrode material, comprises the steps:

[0046] S1. Spherical nano SnO 2 Put the particles into a vacuum oven and dry at 90°C for 11 hours, take them out and put them into a brown reagent bottle to seal for later use;

[0047] S2, dry spherical nano-SnO 2 The particles are put into the atomic layer deposition chamber, the temperature of the chamber is heated to 140°C, and ethylene glycol is used as the pulse precursor for passivation. The passivation time is 40s, and then purged with carrier gas;

[0048] S3. Using the atomic layer deposition method, the spherical nano-SnO loaded with passivation 2 The atomic layer deposition chamber of the particles was heated to 270 °C, using titanium pentaethoxide as the precursor A and deionized water as the precursor B, the passivated spherical nano-SnO 2 The particles are subjected to cyclic deposition and plating, and the cycle is stopped for 55 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com