Ceramic antenna manufacturing method, ceramic antenna and ceramic back cover

A technology of ceramic antenna and manufacturing method, which is applied in the direction of antenna support/installation device, antenna grounding switch structure connection, radiation element structure form, etc., can solve the problem of insufficient antenna radiation clearance space, etc., to improve antenna performance and improve wireless experience effect, guaranteed headroom and height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

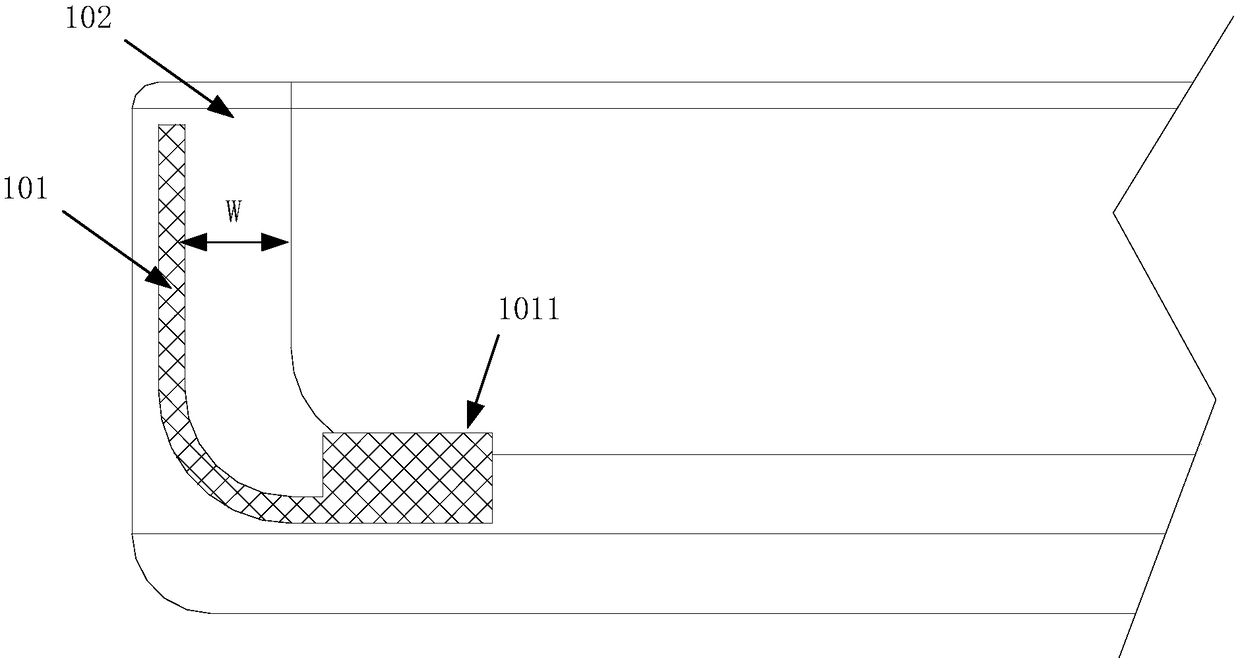

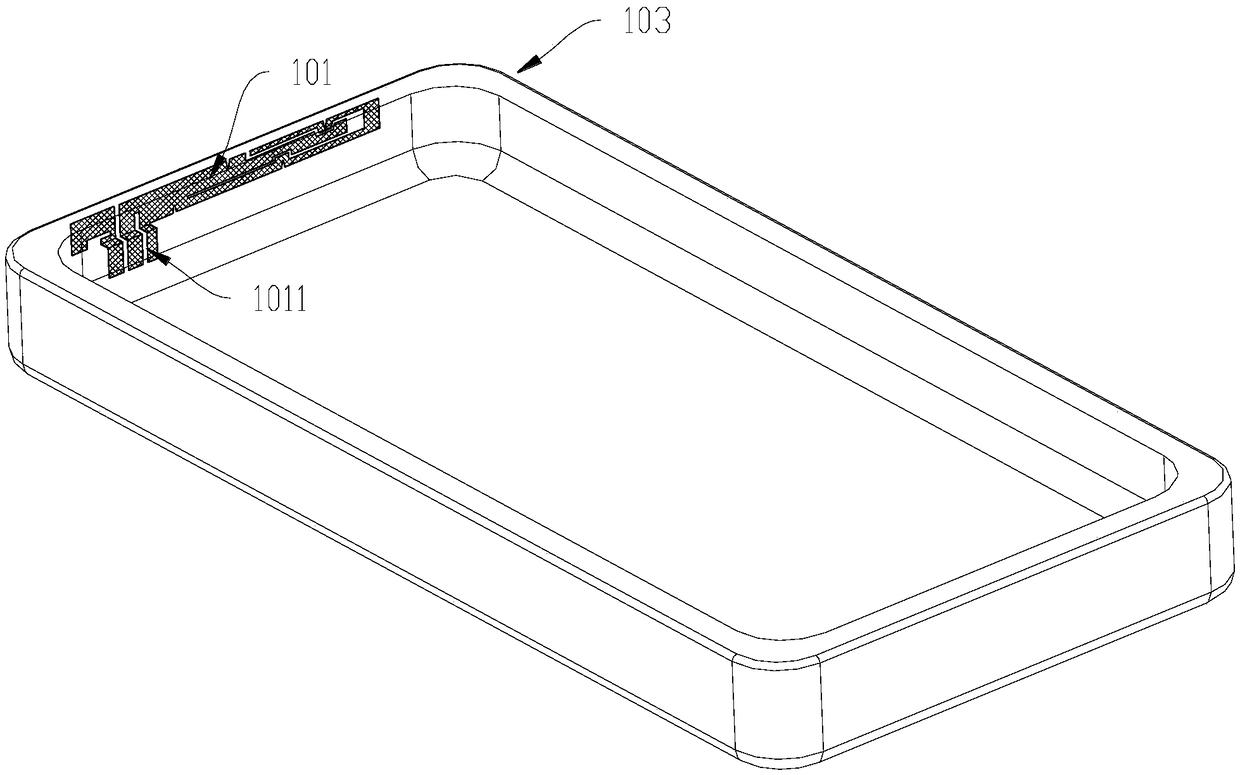

[0025] Such as figure 1 As shown, in an embodiment of a ceramic antenna manufacturing method of the present invention, the following steps are included:

[0026] S1. Mix the ceramic powder and the polymer adhesive to form a slurry; specifically, mix the ceramic powder and the polymer adhesive in proportion to form a fluid mixed slurry. The ceramics here include ceramic materials such as zirconia, and ceramic powders generally use ceramic materials with low dielectric constants. This has minimal impact on the antenna. For example, CaMgSi2O6 ceramics are selected, which is a low dielectric constant ceramic material with excellent performance, which is convenient for antenna radiation.

[0027] S2. The slurry is injecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com