Method for preparing corn noodle and corn noodle

A technology of corn noodles and a production method, applied in the field of food processing, can solve the problems of narrow use surface, weak viscoelasticity, poor processing performance and the like of corn flour, and achieve the effects of good sensory quality, delicate taste and content increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: the influence of the amount of water added on the degree of gelatinization and the determination of the amount of water added when preparing corn gelatinized powder

[0079] Determination of the preparation conditions: crush the corn grits, pass through a 60-mesh sieve, and treat the samples overnight according to the added water of 0%, 5%, 10% and 12%, respectively. Table 1 shows the gelatinization degree of corn flour after extrusion and puffing after adjusting the moisture content of corn flour with different moisture contents. With the increase of water added, the extruded product has a more compact structure and a denser and harder texture, and it can be found that many obvious corn particles cannot be puffed, because the power of puffing depends not only on the form of water in the material It has a great relationship with the combination form and the moisture content, because the material is in the form of fine powder, adding too much moisture will ...

Embodiment 2

[0082] Embodiment 2: The impact of crushing time on the degree of gelatinization of corn gelatinized flour

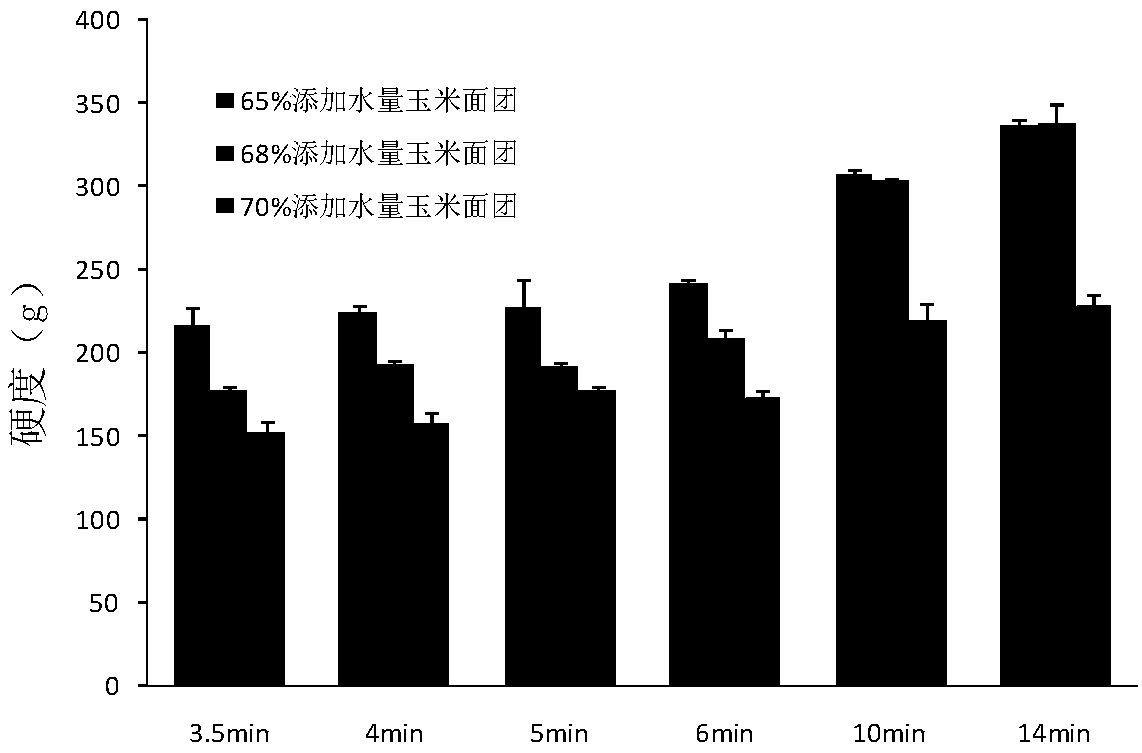

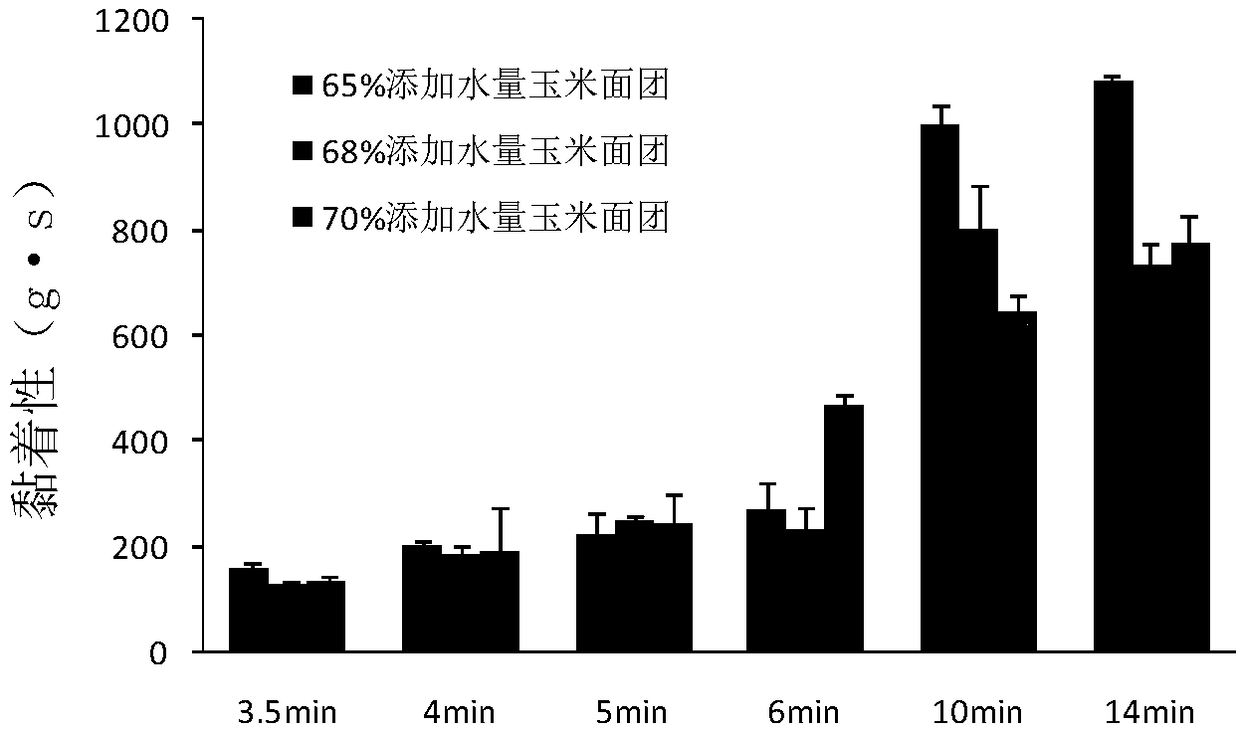

[0083] When the crushing time of corn grits is 3.5min, 4min, 5min, 6min, 10min and 14min, add 65, 68, and 70% distilled water respectively to make corn dough, seal the prepared dough and let it stand for 10 minutes. The structure instrument conducts the TPA secondary pressure texture test, the test parameters are as follows: probe type P / 6, the speed before the test is 1.00mm / s, the speed during the test is 1.00mm / s, the speed after the test is 1.00mm / s, and the interval between two 5s, trigger force 5.0g, repeat 5-8 times for each sample. Test results such as Figure 1 to Figure 3 , under the condition of the same amount of water added, the hardness, stickiness and cohesiveness of corn dough gradually increased with the decrease of particle size. Under the same particle size, the hardness of corn dough decreased and the cohesiveness increased with the increase of wat...

Embodiment 3

[0084] Example 3: Determination of the optimal degree of gelatinization of mixed flour, determining the optimal ratio of corn gelatinized flour and raw corn flour in mixed flour by gelatinization degree

[0085] The degree of gelatinization is 30, 40, 50, 60, 70 and 80% corn dough after adjusting the degree of gelatinization of 20.28% corn raw flour and 94.51% corn gelatinized flour according to the ratio, and measuring TPA ( Texture profile analysis) indicators of hardness, adhesiveness and cohesiveness in the test. Measurement results such as Figure 4 to Figure 6 , marked with different lowercase letters after each value indicates a significant difference (p<0.05). With the increase of gelatinization degree, the hardness (d) of corn dough increases gradually, which is significantly different from that of wheat dough, and both of them are greater than that of wheat dough Hardness; the adhesiveness (e) of the surface decreases gradually, and when the gelatinization degree is 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com