Method for preparing ethyl lipoate by virtue of tubular reactor

A technology of tubular reactor and ethyl lipoic acid, which is applied in chemical instruments and methods, chemical/physical/physical chemical fixed reactors, chemical/physical/physical chemical processes, etc., can solve the problem of shortening reaction time and heat preservation reaction Long time, uncontrollable temperature and other problems, to achieve the effect of shortening the reaction time, improving the yield and quality, and controlling the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

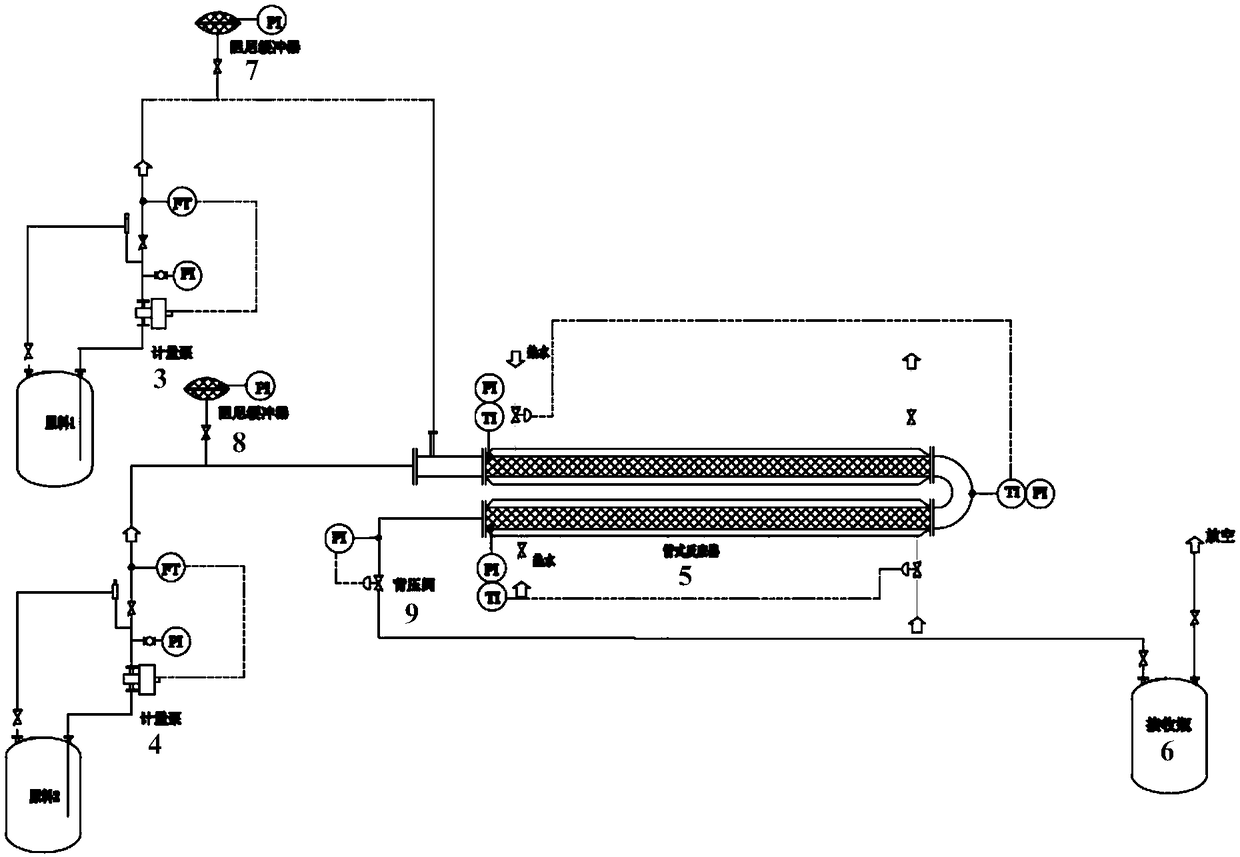

Method used

Image

Examples

Embodiment 1

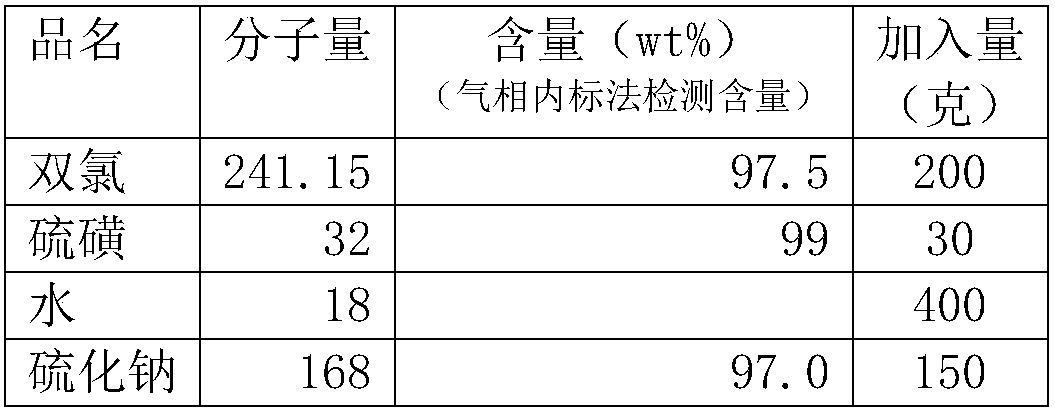

[0037] Preparation of raw material 1 (sodium disulfide): In a 500ml three-necked reaction flask, put sulfur: 30 grams, 400 grams of water, and sodium sulfide pentahydrate: 150 grams, control the internal temperature at 40-50 degrees, and stir to obtain a clear liquid. It weighs 580 grams and is ready to use. (The pump used is metering pump 1)

[0038] Preparation of raw material 2 (ethyl 6,8-dichlorooctanoate): 97.5% of ethyl 6,8-dichlorooctanoate: 200 grams. stand-by. (The pump used is metering pump 2)

[0039] Using liquid-liquid two-phase reaction:

[0040] Set the flow rate of metering pumps 3 and 4 and pump them into the tubular reactor to complete the reaction of raw material 1 and raw material 2 at the same time. That is, the flow rate of raw material 1 is 5.80 g / sec, that is, the flow rate of raw material 2 is 2.0 g / sec. The reaction temperature is controlled to 40°C, the reaction residence time is 30 seconds, and the reaction product is collected. After all the product...

Embodiment 2

[0044] The raw material 1 and raw material 2 in Example 1 were used.

[0045] Set the flow rate of metering pumps 3 and 4 and pump them into the tubular reactor to complete the reaction of raw material 1 and raw material 2 at the same time. That is, the flow rate of raw material 1 is 5.80 g / sec, that is, the flow rate of raw material 2 is 2.0 g / sec. The reaction temperature is controlled at 60°C, the reaction residence time is 36 seconds, and the reaction product is collected. After all the products are collected, they are extracted with toluene. After the toluene is evaporated on a rotary evaporator, 197.80 grams are weighed. The content of ethyl lipoic acid in the product was 95.65%, and the yield was 96.41%.

Embodiment 3

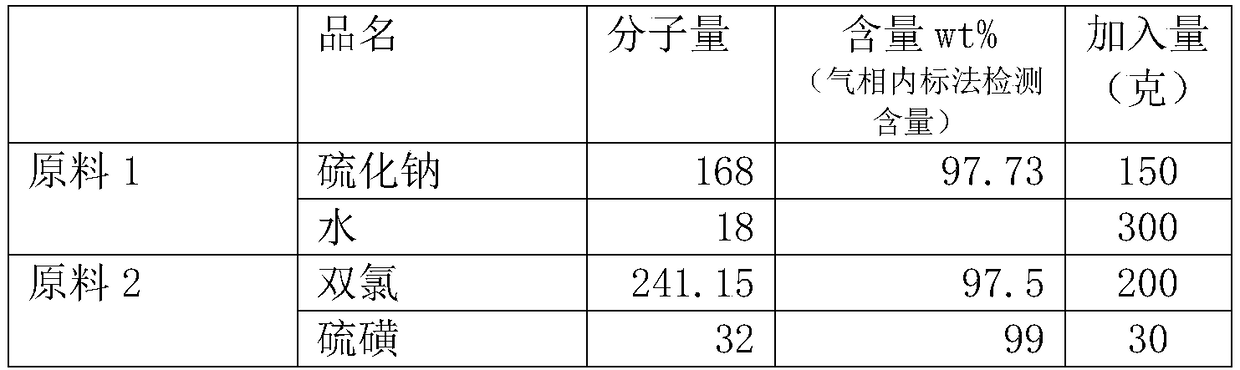

[0047] Raw material 1: Preparation of (sodium sulfide): 300 grams of water and 150 grams of sodium sulfide pentahydrate in a 500m beaker, the internal temperature is controlled at 50 degrees, and the mixture is stirred to obtain a clear liquid, with a total weight of 450 grams, ready for use. (The pump used is metering pump 1)

[0048] Preparation of raw material 2 (sulfur powder and solid suspension of ethyl 6,8-dichlorooctanoate): 30 grams of sulfur powder and 97.5% of ethyl 6,8-dichlorooctanoate: 200 grams, total weight 230 grams. In the stirring beaker, keep stirring to evenly distribute the sulfur in the liquid, and set aside. (The pump used is metering pump 2)

[0049] Solid-liquid two-phase reaction:

[0050] Set the flow rate of metering pumps 3 and 4 and pump them into the tubular reactor to complete the reaction of raw material 1 and raw material 2 at the same time. That is, the flow rate of raw material 1 is 4.50 g / sec, that is, the flow rate of raw material 2 is 2.30 g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com