Roadbed construction technology suitable for saline soil areas

A construction process and saline soil technology, applied in roads, roads, buildings, etc., can solve the problems of normal operation impact, shortened service life, waste of resources, etc., to reduce construction costs, salt swelling, and maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A roadbed construction process suitable for saline soil areas. It includes the following steps. The first step is to detect the salt content of the original ground. If the salt content exceeds the standard, excavate the soil within a range of not less than 1.0m below the ground surface. When the design height of the embankment is less than 1.0m, the soil within the range of not less than 1.0m below the ground surface must be excavated and replaced with water-permeable soil to the original ground height. If the salt content is qualified, no treatment will be performed;

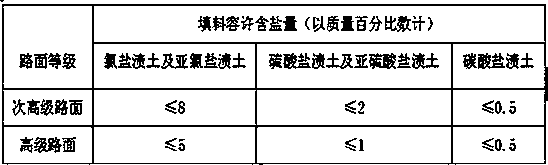

[0036] In the first step, the salt content standard is shown in Table 1.

[0037] Allowable salt content on the ground in saline soil area Table 1

[0038]

[0039] If the original ground soil is chlorinated saline soil and chlorite saline soil, the salt content shall not exceed 5%; if the original ground soil is sulfate saline soil and sulfite saline soil, the salt content shall not exceed 1%; if the original ...

Embodiment 2

[0050] The selection and treatment of fillers in the second step includes the following steps:

[0051] Step 1. Select the type of filler, and select the type of filler according to the filling layer of the filler, that is, the distance between the position of the filler and the top layer of the subgrade;

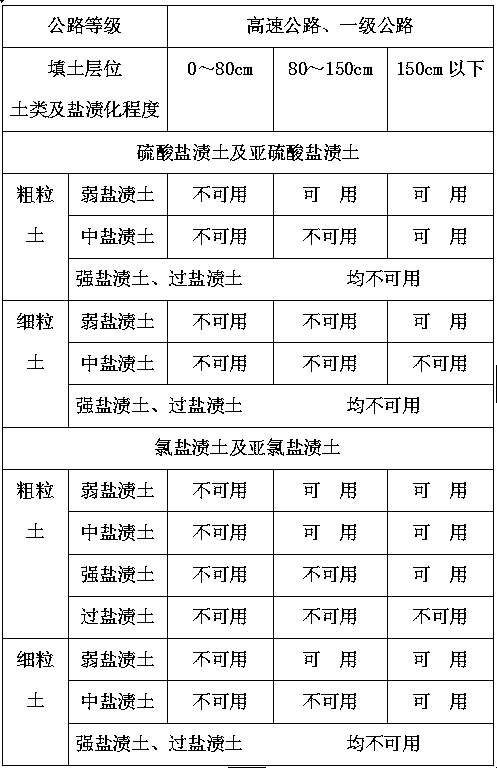

[0052] In the first step, the specific method for selecting the filler type according to the fill layer is shown in Table 2.

[0053] Availability of saline soil as roadbed filler Table 2

[0054]

[0055] If the fill layer is within 0-80cm, use gravel or aeolian sand as the filler; if the fill layer is within 80-150cm, use coarse-grained weakly saline soil among sulfated saline soil and sulfite saline soil And coarse-grained weakly saline soil in chlorinated saline soil and chlorinated saline soil, coarse-grained medium-grained saline soil and fine-grained weakly saline soil as fillers; if the fill layer is below 150cm, use saline soil And the coarse-grained weak saline soil in t...

Embodiment 3

[0061] In the fourth or eighth step, the water content of the filler is tested before paving the filler. If the filler is gravel or sandy soil, the water content of the soil is -2% to +3% of the optimal water content If the filling field is any soil material except gravel soil or sandy soil, the water content of the soil material is ±1% of the optimal water content. If the water content exceeds the standard, the filling is aired. If it is too low, water the filler. When sprinkling, choose a sprinkler above 10L for sprinkling. It is best to sprinkle in the afternoon or evening to reduce the influence of water evaporation. At the same time, rain will affect the water content of the filler, so no construction is done on rainy days.

[0062] In the fourth and eighth steps, the thickness of the paving layer of filler does not exceed 30 cm.

[0063] In the sixth and tenth steps, the surface of the compacted packing has a slope of not less than 1.5%.

[0064] In the seventh step, the barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com