A gas sensitive material used for monitoring ammonia gas emission for environment and a preparation method thereof

A gas-sensitive material and environmental monitoring technology, which is applied in the direction of analyzing materials, material resistance, and material analysis through electromagnetic means, can solve problems such as poor long-term stability, poor selectivity, and the influence of ammonia environment temperature and humidity, and achieve accurate measurement and Effects of control, improvement of detection ability, and ease of industrialization development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

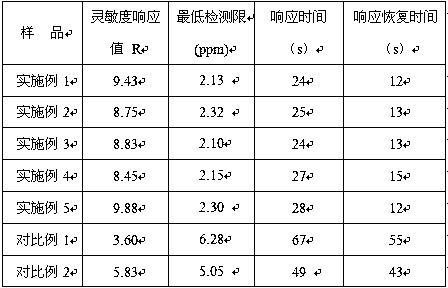

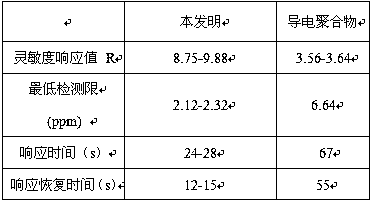

Examples

Embodiment 1

[0032] (1) Weigh polyvinylpyrrolidone and absolute ethanol at a mass ratio of 3:7, add the polyvinylpyrrolidone to the absolute ethanol, set the stirring speed to 200rpm, and stir at a constant speed to obtain Solution A;

[0033] (2) Weigh the soluble vanadium salt and N,N-dimethylformamide according to the mass ratio of 1:9, add the soluble vanadium salt to the N,N-dimethylformamide, set the stirring The speed is 200rpm, stirring at a constant speed to obtain solution B;

[0034] (3) Mix solution A and solution B with a volume ratio of 1:2, pour the solution A into the solution B, then add a nitric acid solution with a concentration of 0.5mol / L and stir to obtain vanadium pentoxide Precursor solution; the amount added is 2% of the total mass of solution A and solution B.

[0035] (4) Add the precursor solution of vanadium pentoxide obtained in step (3) into the electrospinning equipment, and through the electrospinning process, use an air pump to advance at a speed of 0.3mL / ...

Embodiment 2

[0039] (1) Weigh polyvinylpyrrolidone and absolute ethanol at a mass ratio of 4:6, add the polyvinylpyrrolidone into the absolute ethanol, set the stirring speed to 100rpm, and stir at a constant speed to obtain Solution A;

[0040] (2) Weigh the soluble vanadium salt and N,N-dimethylformamide according to the mass ratio of 2:8, add the soluble vanadium salt to the N,N-dimethylformamide, set stirring The speed is 100rpm, stirring at a constant speed to obtain solution B;

[0041] (3) Mix solution A and solution B with a volume ratio of 1:3, pour the solution A into the solution B, then add a nitric acid solution with a concentration of 1.0 mol / L and stir to obtain vanadium pentoxide Precursor solution; the amount added is 2% of the total mass of solution A and solution B.

[0042] (4) Add the precursor solution of vanadium pentoxide obtained in step (3) to the electrospinning equipment, and through the electrospinning process, use an air pump to advance at a speed of 0.45mL / ...

Embodiment 3

[0046] (1) Weigh polyvinylpyrrolidone and absolute ethanol according to a mass ratio of 3:6.5, add the polyvinylpyrrolidone into the absolute ethanol, set the stirring speed to 80rpm, and stir at a constant speed to obtain Solution A;

[0047] (2) Weigh the soluble vanadium salt and N,N-dimethylformamide according to the mass ratio of 2:9, add the soluble vanadium salt to the N,N-dimethylformamide, set the stirring The speed is 80rpm, stirring at a constant speed to obtain solution B;

[0048] (3) Mix solution A and solution B with a volume ratio of 1-3:2-4, pour the solution A into the solution B, then add a nitric acid solution with a concentration of 0.9mol / L and stir to obtain five Precursor solution of vanadium oxide; the amount added is 2% of the total mass of solution A and solution B.

[0049] (4) Add the vanadium pentoxide precursor solution obtained in step (3) into the electrospinning equipment, and through the electrospinning process, use an air pump to advance a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com