High-efficiency cooking and decyanation process of flaxseeds

A flaxseed cooking technology, which is applied in the field of high-efficiency cooking and decyanation of flaxseed, can solve the problems of high baking temperature, long cooking time, and high puffing temperature, and achieve the effect of simple and fast operation and long-term preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

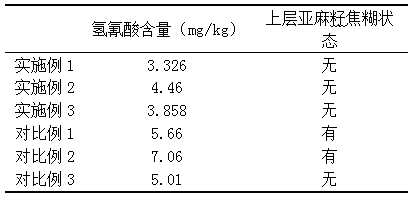

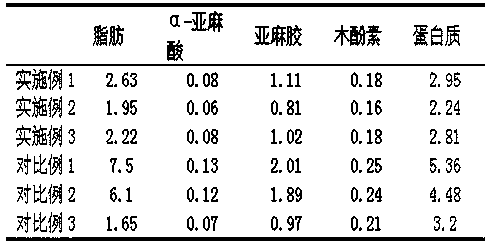

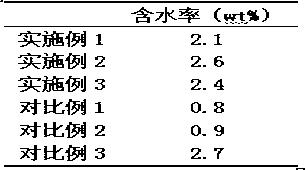

Examples

Embodiment 1

[0020] (1) Pass the linseed through an 8-mesh sieve to remove larger impurities, then pass through a 20-mesh sieve to remove immature seeds and smaller impurities, and then go through winnowing to remove shriveled and inferior seeds, select mature flaxseeds with full grains, and evenly Lay on the conveyor belt with a laying thickness of 5cm;

[0021] (2) Heat for 15 seconds under a microwave with a power of 280W;

[0022] (3) Spray evenly on the surface of flaxseed with 90°C hot water, and then keep penetrating for 50 seconds;

[0023] (4) Dry with 680W microwave for 60 seconds.

Embodiment 2

[0025] (1) Pass the linseed through a 10-mesh sieve to remove larger impurities, then pass through a 24-mesh sieve to remove immature seeds and smaller impurities, and then go through winnowing to remove shriveled and inferior seeds, select mature flaxseeds with full grains, and evenly Lay on the conveyor belt with a laying thickness of 8cm;

[0026] (2) Heat for 20 seconds under a microwave with a power of 350W;

[0027] (3) Spray evenly on the surface of linseed with 90°C hot water, and keep penetrating for 60 seconds;

[0028] (4) Dry with 680W microwave for 50 seconds.

Embodiment 3

[0030] (1) Pass the linseed through an 8-mesh sieve to remove larger impurities, then pass through a 20-mesh sieve to remove immature seeds and smaller impurities, and then go through winnowing to remove shriveled and inferior seeds, select mature flaxseeds with full grains, and evenly Lay on the conveyor belt with a laying thickness of 5cm;

[0031] (2) Heat for 20 seconds under a microwave with a power of 300W;

[0032] (3) Spray evenly on the surface of linseed with hot water at 60°C, and keep penetrating for 60 seconds;

[0033] (4) Dry with 680W microwave for 60 seconds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com