Method for preparing black garlic through enzymatic browning and application

A black garlic and browning technology, which is applied in the field of enzymatic browning to prepare black garlic, can solve the problems of high cost, long production cycle, and low efficiency, and achieve the effects of improving efficiency, good sensory quality, and promoting browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] According to the following steps, prepare the black garlic of embodiment 1:

[0064] Use whole, unpeeled, plump, insect-free, and mildew-free garlic as raw materials; remove the obviously damaged skin of the garlic, rinse it and drain it;

[0065] Put the processed garlic into a sterilized airtight jar with a cardboard on the bottom of the airtight jar and a dry paper towel on top of the airtight jar;

[0066] Put the sealed jar with garlic in a constant temperature water bath at 70°C, and pre-heat for 5 hours;

[0067] Take the garlic out of the airtight jar, then peel it until only the innermost skin remains, and then evenly spray the prepared polyphenol oxidase solution on the surface of the garlic;

[0068] Then, put the garlic into a sealed jar, put the sealed jar with garlic into a constant temperature water bath at 60° C., and heat it for 40 days to obtain the black garlic of Example 1.

Embodiment 2

[0070] According to the following steps, prepare the black garlic of embodiment 2:

[0071] Use whole, unpeeled, plump, insect-free, and mildew-free garlic as raw materials; remove the obviously damaged skin of the garlic, rinse it and drain it;

[0072] Put the processed garlic into a sterilized airtight jar with a cardboard on the bottom of the airtight jar and a dry paper towel on top of the airtight jar;

[0073] Put the sealed jar with garlic in a constant temperature water bath at 70°C, and heat it for pretreatment for 10 hours;

[0074] Take the garlic out of the airtight jar, then peel it until only the innermost skin remains, and then evenly spray the prepared polyphenol oxidase solution on the surface of the garlic;

[0075] Then, put the garlic into a sealed jar, put the sealed jar with the garlic into a constant temperature water bath at 60° C., heat it for 40 days, and obtain the black garlic of Example 2.

experiment example 1

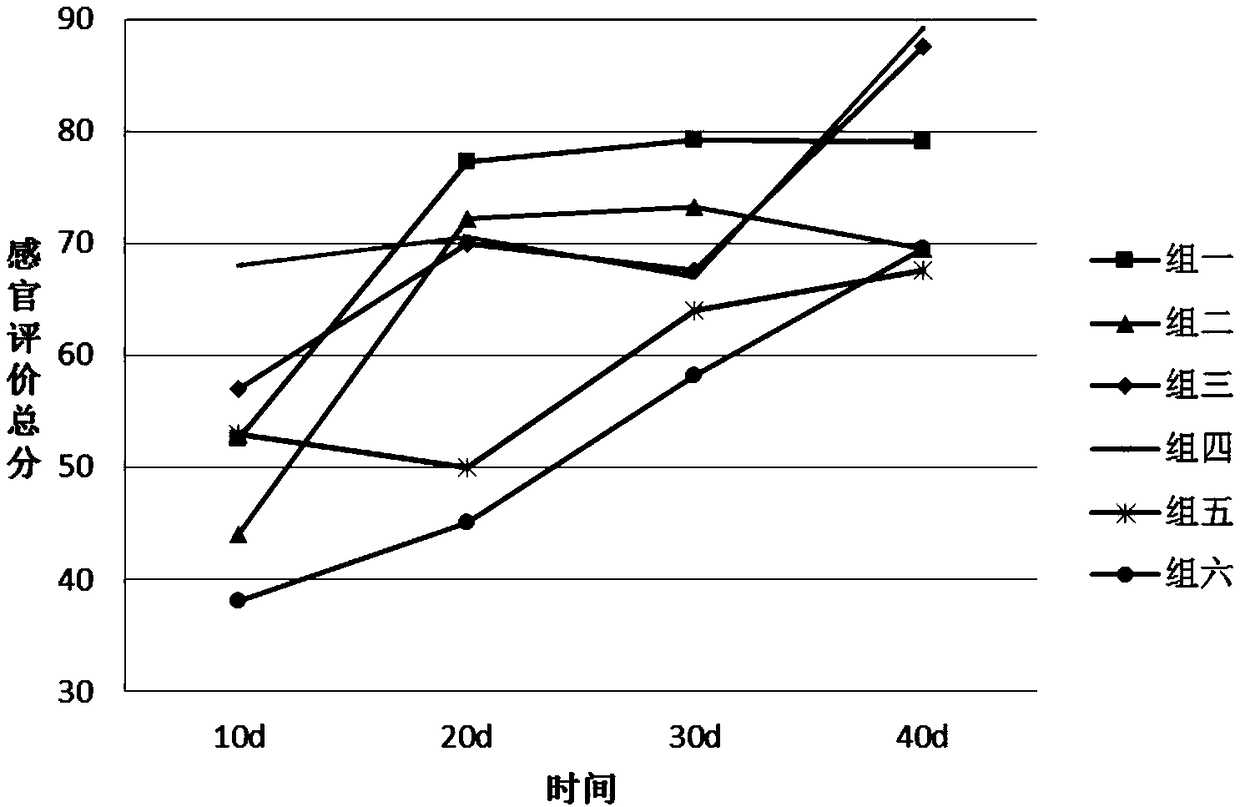

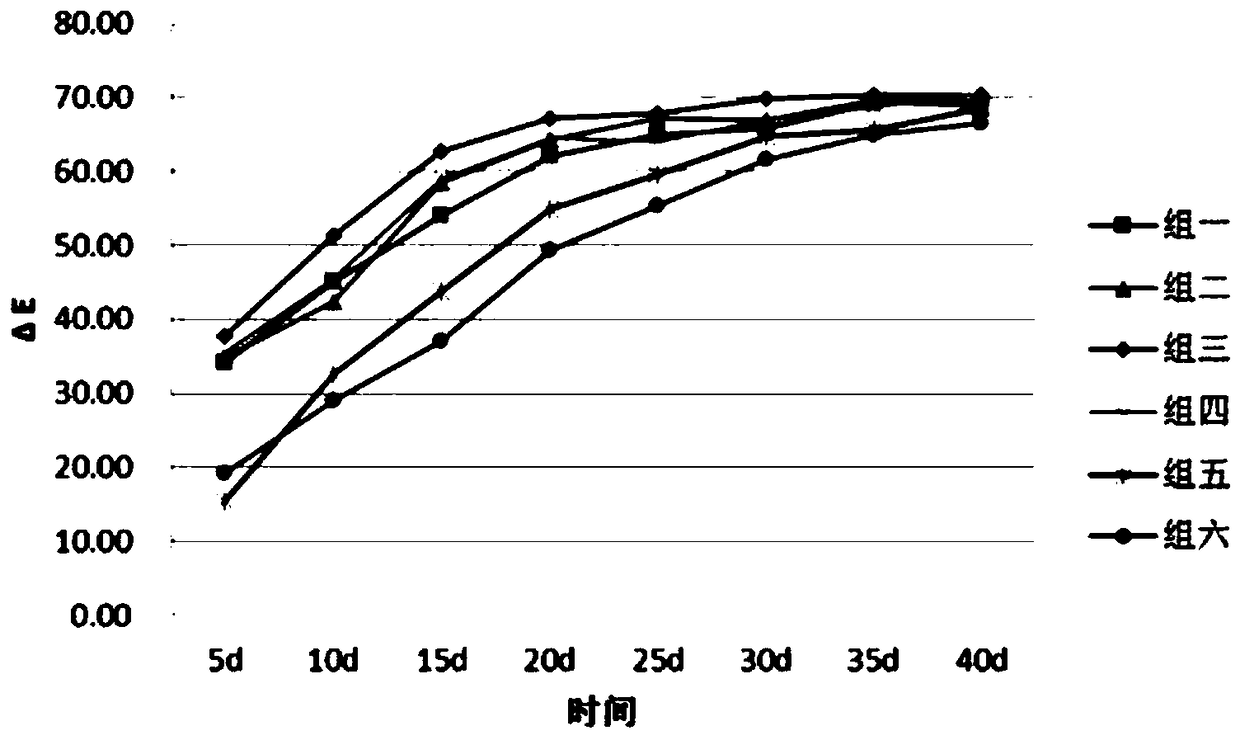

[0095] During the preparation process and after the preparation, flavor evaluation was carried out for the black garlic of each embodiment and comparative example products, and the browning situation of different groups of black garlic at each stage was detected;

[0096] Simultaneously, in order to facilitate a more intuitive comparison of the effects of different processing methods on the sensory and browning degrees of black garlic, in the following experiments, Example 1 is recorded as Group One, and Comparative Example 1 is recorded as Group Two; is group three, comparative example 2 is recorded as group four; comparative example 3 is recorded as group five, and comparative example 4 is recorded as group six.

[0097] (1) Senses of black garlic:

[0098] Select black garlic from each group fermented at 60°C for 10 days, 20 days, 30 days, and 40 days, and select 10 persons to conduct sensory evaluation on the black garlic. Before the sensory evaluation, explain the conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com