Fluidized-bed apparatus and method to co-produce p-xylene and light olefins by methanol and/or dimethyl ether and benzene

A technology of p-xylene and low-carbon olefins, which is applied in the field of equipment for the production of p-xylene and low-carbon olefins, and can solve the problems of complex process, low benzene conversion rate, high benzene conversion rate and high p-xylene yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

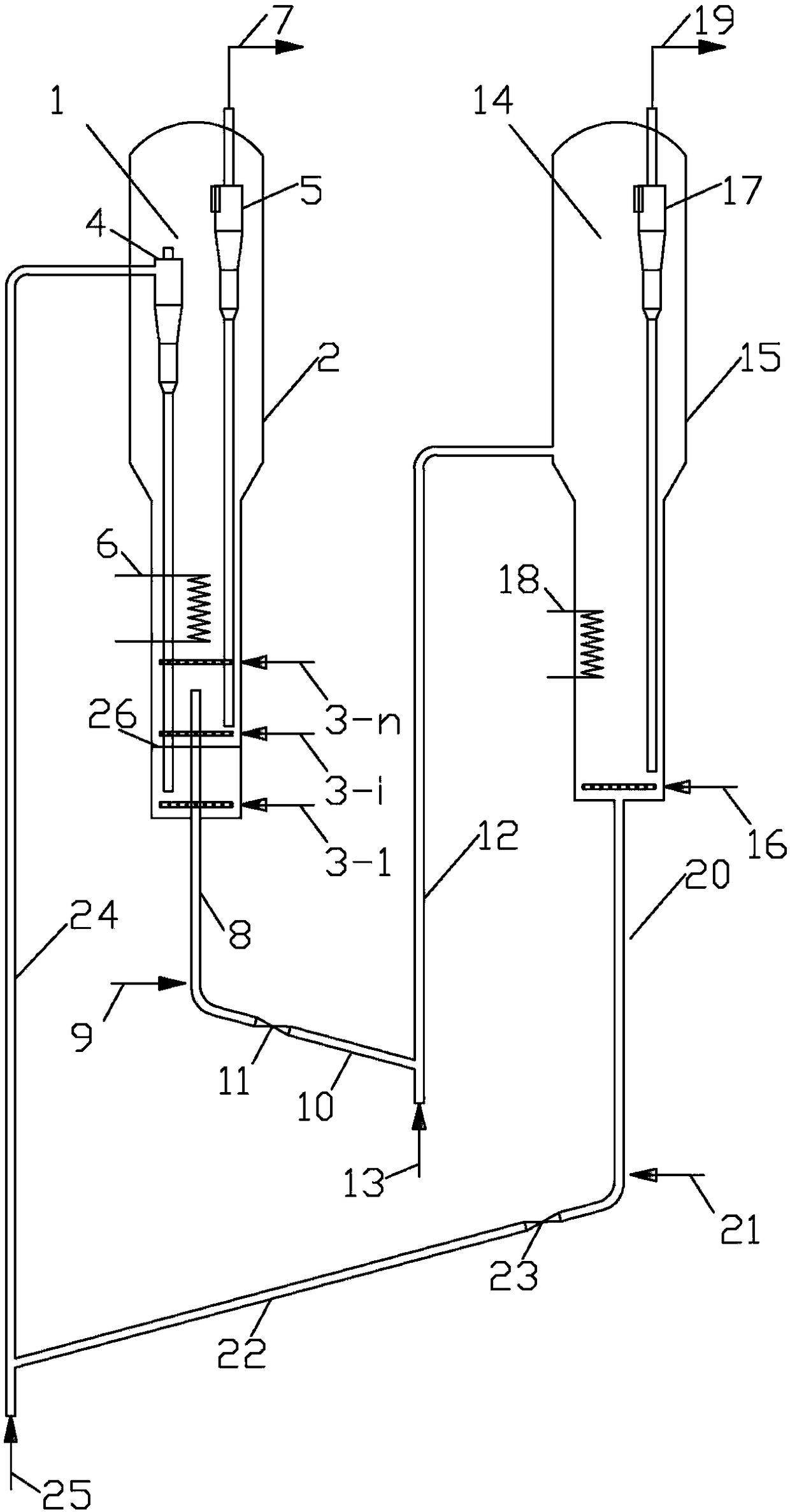

[0123] use figure 1 The device shown, but the turbulent fluidized bed reactor 1 does not include the reactor gas-solid separator 4 and the perforated plate 26, and the regeneration riser 24 is directly connected to the dilute phase zone of the turbulent fluidized bed reactor 1. The turbulent fluidized bed reactor 1 contains a reactor feed distributor 3-1.

[0124] The reaction conditions in the reaction zone of the turbulent fluidized bed reactor 1 are: the superficial linear velocity of the gas is about 1.0m / s, the reaction temperature is about 500°C, the reaction pressure is about 0.15MPa, and the bed density is about 350kg / m3.

[0125] The reaction conditions in the regeneration zone of the fluidized bed regenerator 14 are: the apparent linear velocity of the gas is about 1.0m / s, the regeneration temperature is about 650°C, the regeneration pressure is about 0.15MPa, and the bed density is about 350kg / m3.

[0126] The catalyst contains HZSM-5 molecular sieve, and the carbo...

Embodiment 2

[0131] use figure 1 In the shown device, the turbulent fluidized bed reactor 1 contains 3 reactor feed distributors 3-1 to 3-3, the opening ratio of the porous plate 26 is 10%, and the reactor gas-solid separator 4 is placed Inside the reactor shell 2.

[0132] The reaction conditions in the reaction zone of the turbulent fluidized bed reactor 1 are: the superficial linear velocity of the gas is about 1.0m / s, the reaction temperature is about 500°C, the reaction pressure is about 0.15MPa, and the bed density is about 350kg / m3.

[0133] The reaction conditions in the regeneration zone of the fluidized bed regenerator 14 are: the apparent linear velocity of the gas is about 1.0m / s, the regeneration temperature is about 650°C, the regeneration pressure is about 0.15MPa, and the bed density is about 350kg / m3.

[0134] The catalyst contains HZSM-5 molecular sieve, and the carbon content of the regenerated catalyst is about 0.1 wt.%.

[0135] The regeneration medium is air; the st...

Embodiment 3

[0145] use figure 1 In the shown device, the turbulent fluidized bed reactor 1 contains 6 reactor feed distributors 3-2 to 3-6, the opening ratio of the porous plate is 5%, and the reactor gas-solid separator 4 is placed in the reaction Inside the device housing 2.

[0146] The reaction conditions in the reaction zone 1 of the turbulent fluidized bed reactor are: the apparent linear velocity of the gas is about 0.8m / s, the reaction temperature is about 560°C, the reaction pressure is about 0.6MPa, and the bed density is about 460kg / m 3 .

[0147] The reaction conditions in the regeneration zone of the fluidized bed regenerator 14 are: the apparent linear velocity of the gas is about 1.7m / s, the regeneration temperature is about 600°C, the regeneration pressure is about 0.6MPa, and the bed density is about 220kg / m 3 .

[0148] The catalyst contains HZSM-11 molecular sieve, and the carbon content of the regenerated catalyst is about 0.15wt.%.

[0149] The regeneration medium i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com