Diesel oil deep hydrogenation catalyst and preparation method and application thereof

A deep hydrogenation and catalyst technology, applied in the direction of catalyst carriers, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of impregnation effect, active component cluster effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

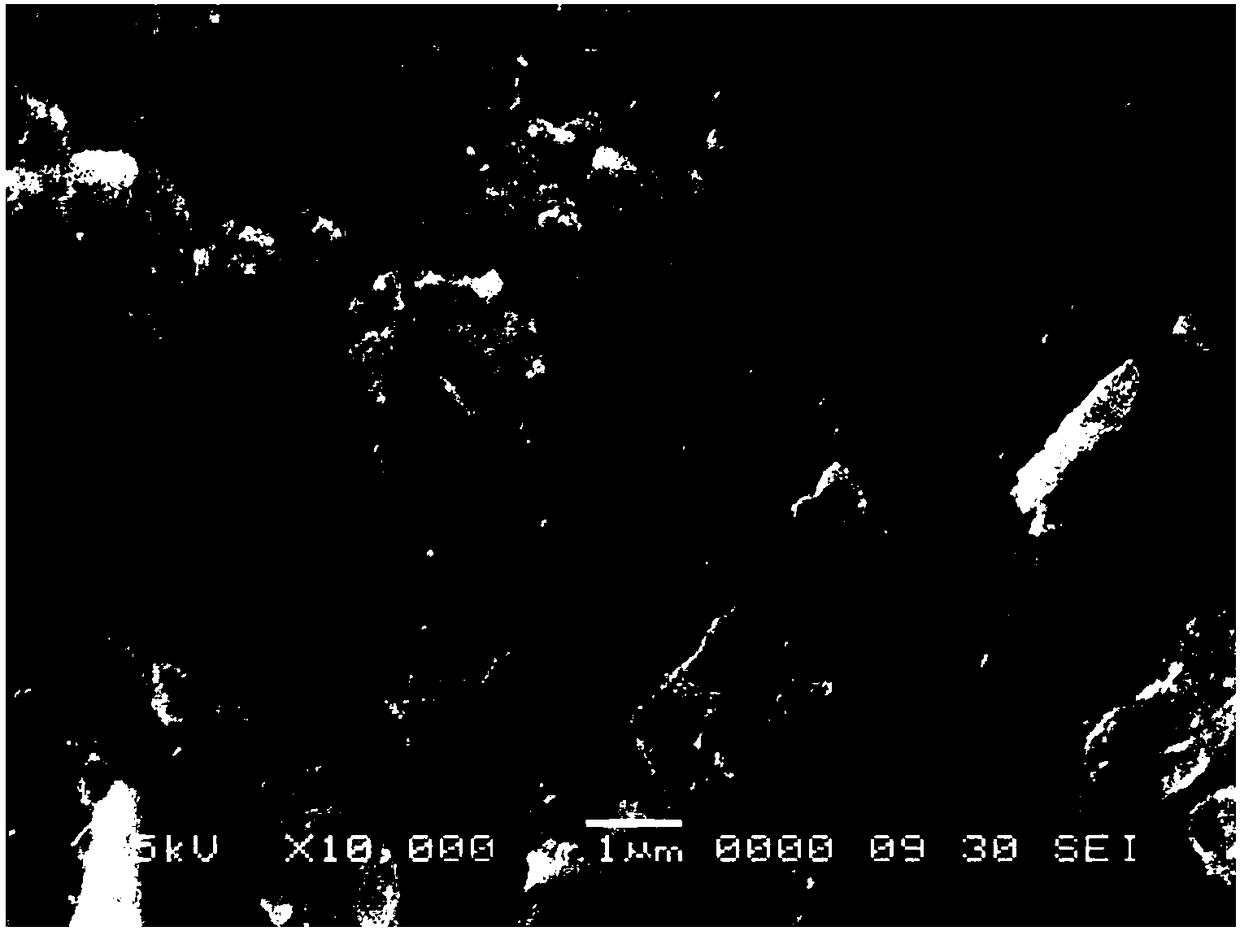

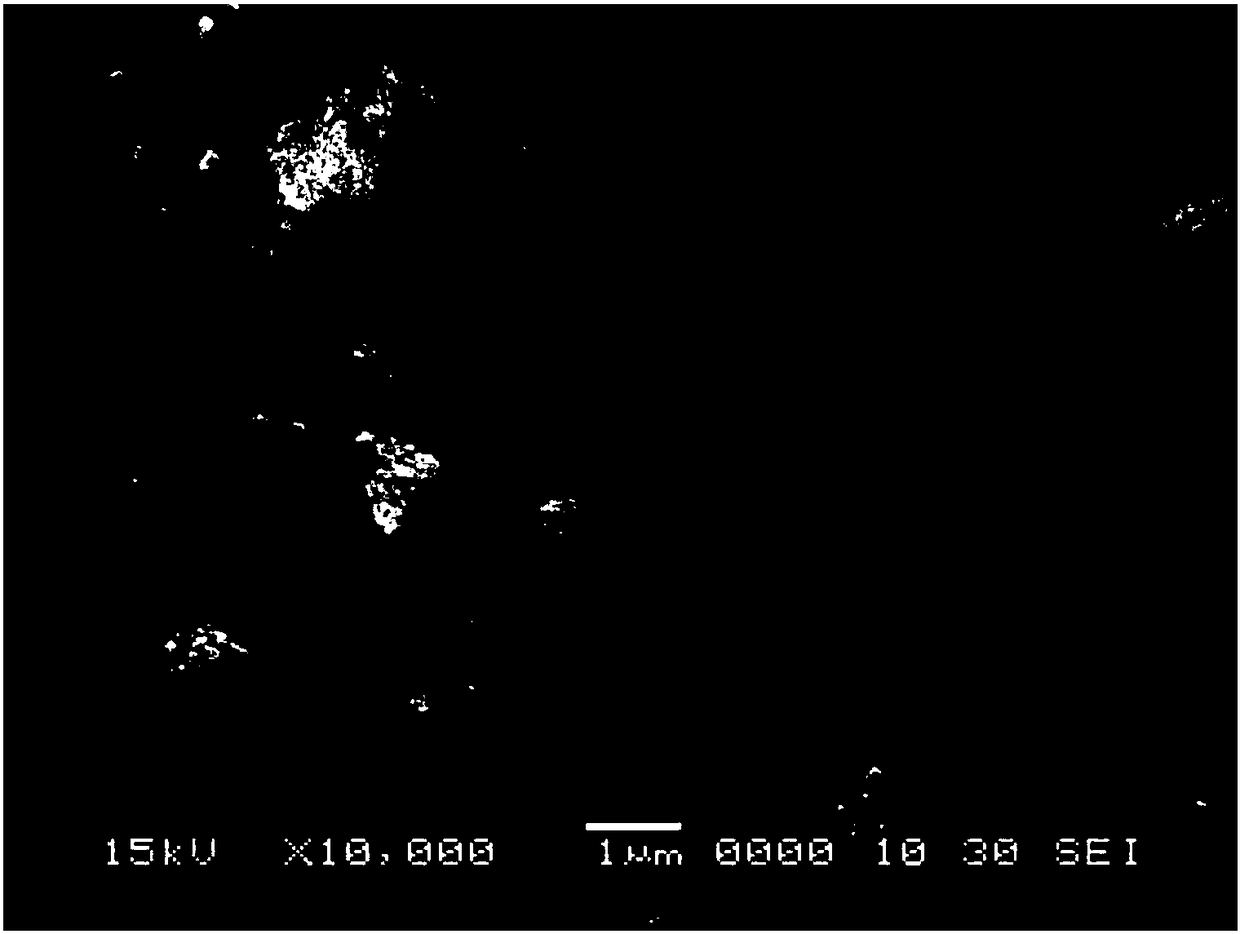

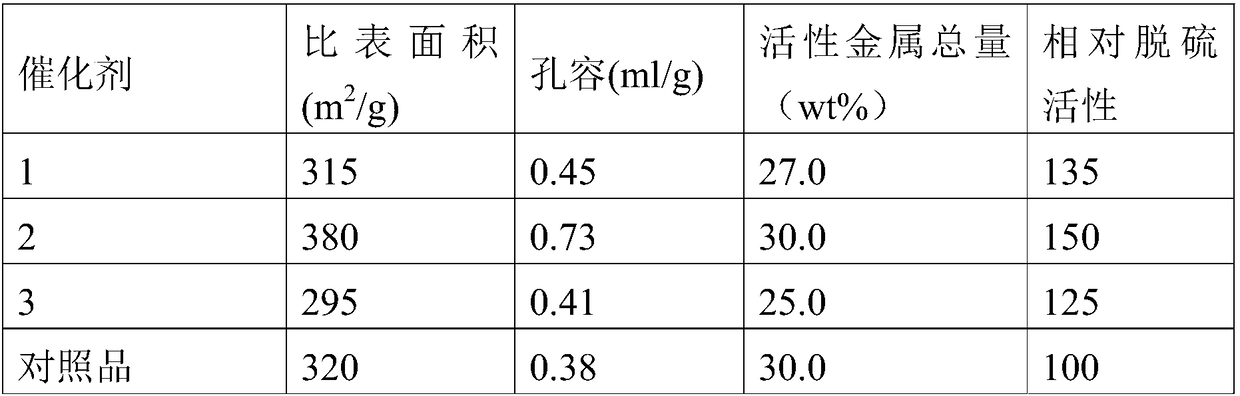

[0042] Get benchmark pseudo-boehmite 100g, 5wt% mulberry silk solid fiber silk, add 5wt% turnip powder and mix evenly, 7.5wt% nitric acid (65wt%), 5wt% citric acid and 100g deionized water form the mixed solution kneading, Extruded into a clover shape of 1.5 mm, dried at 120° C. for 2 hours, and then calcined at 550° C. for 4 hours to make carrier 1 .

Embodiment 2

[0044] Get benchmark pseudo-boehmite 100g, 10wt% coniferous wood solid fiber silk, add 5wt% turnip powder and mix evenly, 7.5wt% nitric acid (65wt%), 5wt% citric acid and 100g deionized water form the mixed solution kneading, Extruded into a clover shape of 1.5mm, dried at 120°C for 2 hours, and then calcined at 550°C for 4 hours to make carrier 2.

Embodiment 3

[0046] Get benchmark pseudo-boehmite 100g, 20wt% corn stalk solid fiber filaments, add 5wt% turnip powder and mix evenly, 7.5wt% nitric acid (65wt%), 5wt% citric acid and 100g deionized water form the mixed solution kneading, Extruded into a clover shape of 1.5 mm, dried at 120° C. for 2 hours, and then calcined at 550° C. for 4 hours to make carrier 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com