Protecting door for numerically controlled machine tool

A technology of CNC machine tools and protective doors, which is applied in the field of CNC machine tools, can solve problems such as blurred glass surfaces, collision damage between protective doors and fuselages, and increased noise, and achieve cumbersome replacement processes, easy disassembly and replacement, and scientific and reasonable structures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

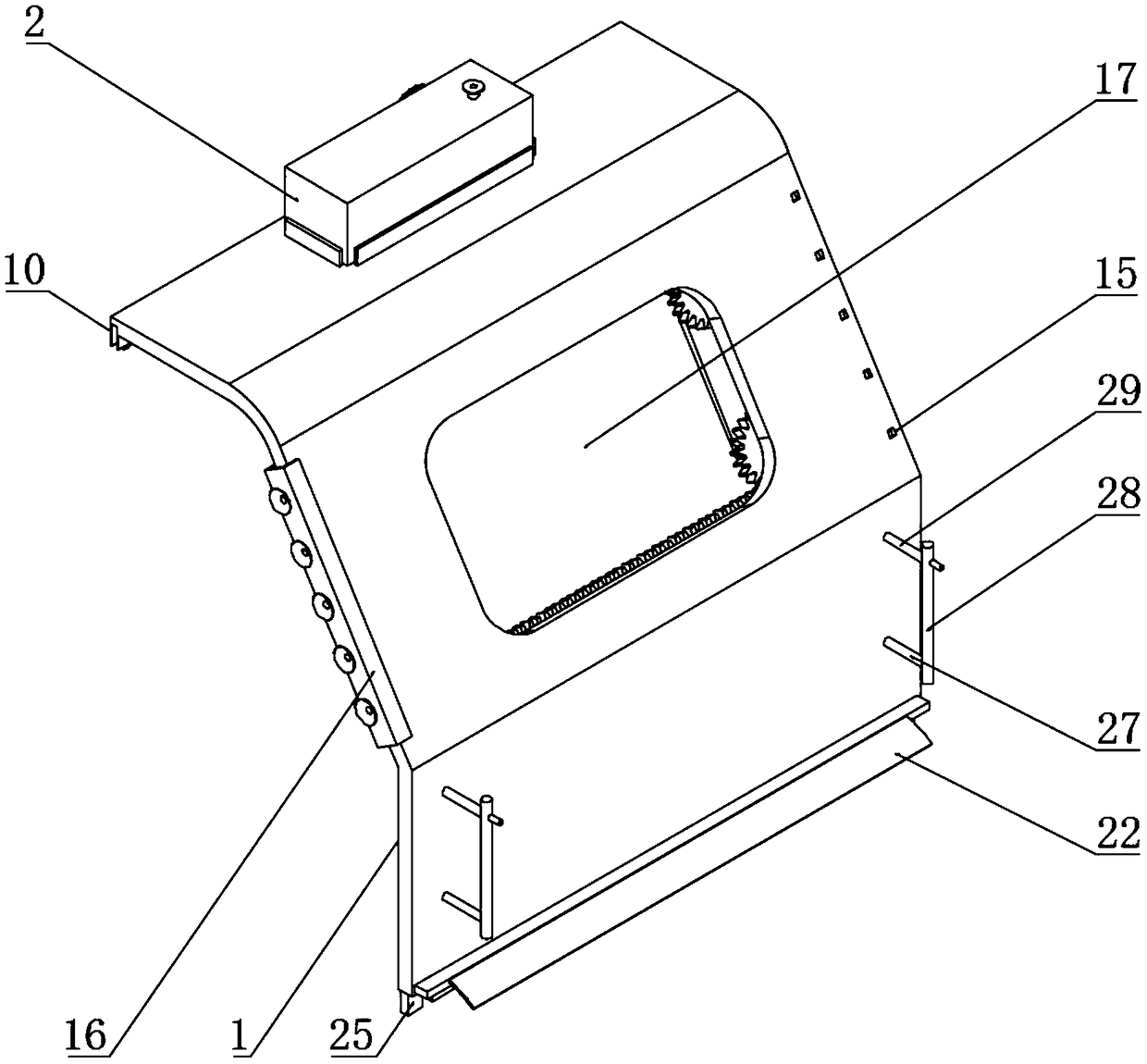

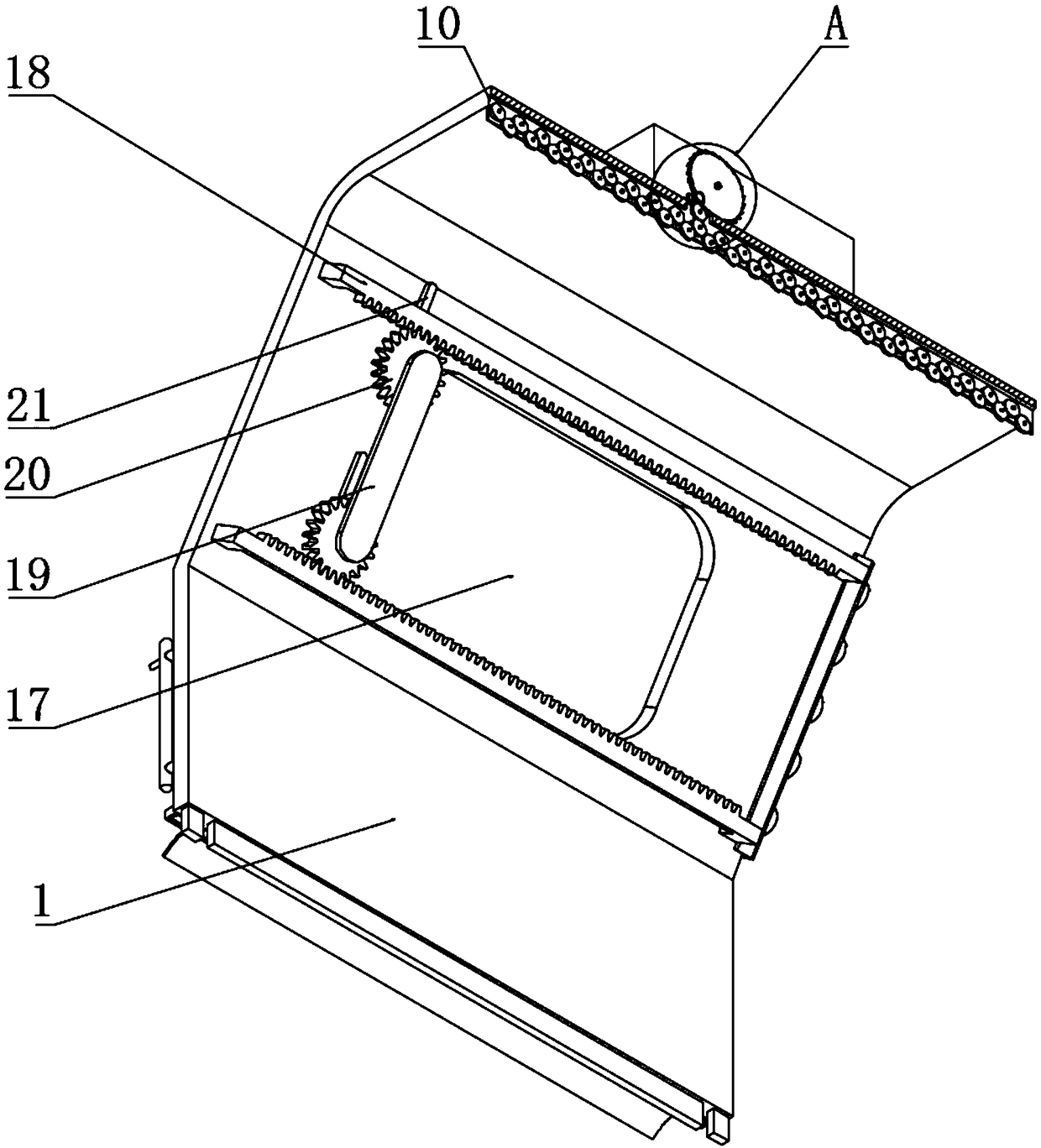

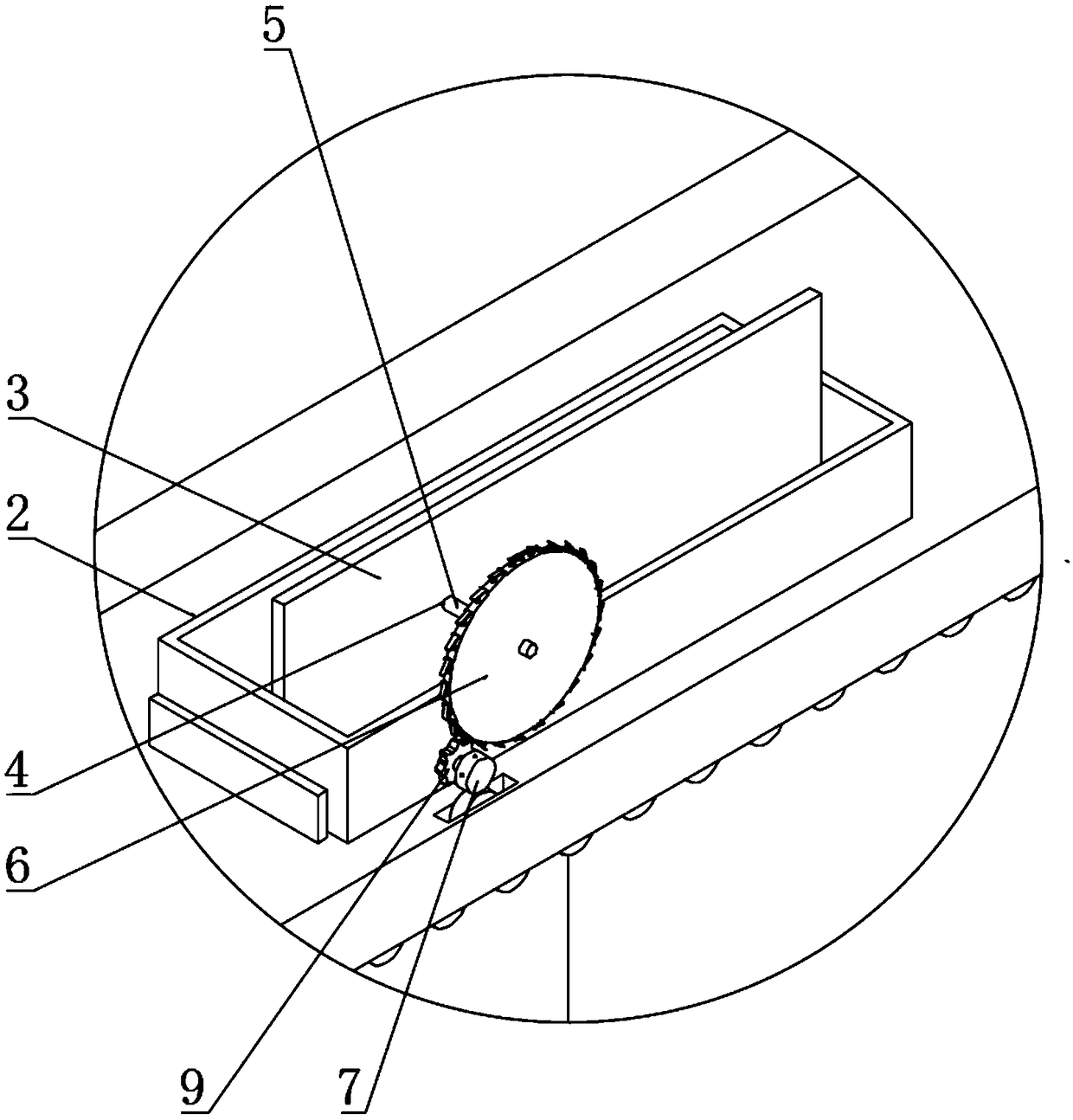

[0033] Example: such as Figure 1-8As shown, the present invention provides a technical solution, a protective door for numerically controlled machine tools, including a door body 1, and a lubricating oil tank 2 is installed on the top of the door body 1, in order to ensure the stability of the lubricating oil tank 2 after installation, and prevent the lubricating oil tank 2 from being arbitrarily Shaking, the top of the door body 1 is equipped with a limit baffle at the position corresponding to the outer side of the lubricating oil tank 2, the inside of the lubricating oil tank 2 is installed with an extrusion plate 3, the middle of the extrusion plate 3 is provided with an adjustment screw hole 4, and the middle of the adjustment screw hole 4 is installed with a screw 5. A ratchet mechanism 6 is installed on one side of the screw rod 5 outside the lubricating oil tank 2. The ratchet mechanism 6 includes a mounting plate 601, a mounting frame 602, an adjustment clamp 603 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com