A Method of Cleaning and Grinding Large Castings Based on Human-Machine Collaboration

A large-scale casting, human-machine collaboration technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

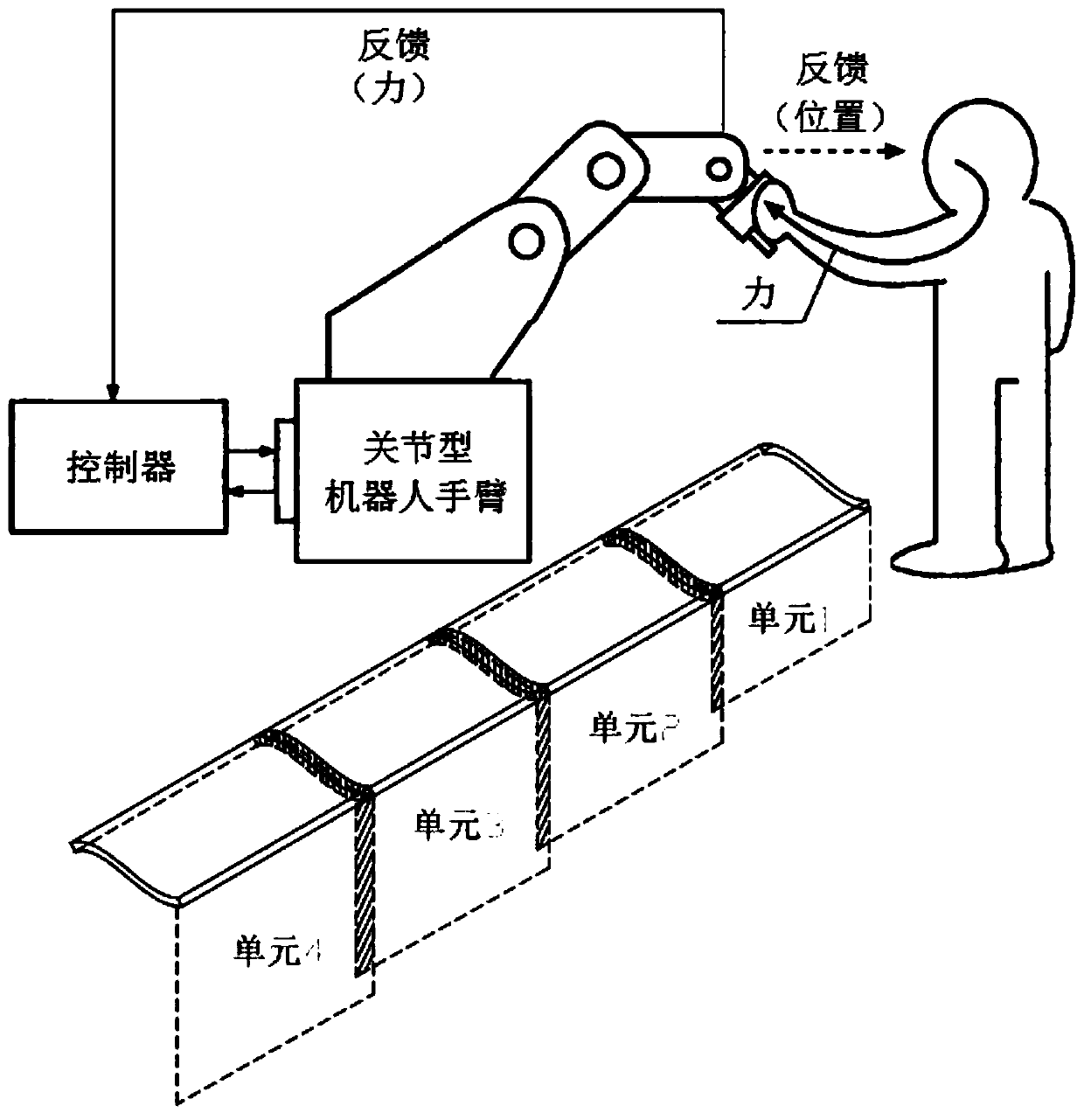

[0039] A method for cleaning and grinding large-scale castings based on human-computer cooperation, comprising the following steps:

[0040] Divide large castings into several units for grinding, the size of each unit is smaller than the working range of the robot used, and there is a small overlap area between two adjacent units;

[0041] Install the circular track, install the industrial robot on the circular track, and place the casting to be polished in the casting circular track;

[0042] Two industrial robot units are used as the main body of the operation, and the two robots are distributed on both sides of the casting. Each robot can move on the circular track separately, and each grinds the two sides of the casting;

[0043] Move the robot to the corresponding position of the unit that needs to be polished to ensure that the working range of the robot can cover the unit that needs to be polished;

[0044] After the robot is in the unit that needs to be polished, dire...

Embodiment 2

[0049] A method for cleaning and grinding large-scale castings based on human-computer cooperation, comprising the following steps:

[0050] Install the robot on the beam and column of the gantry machine tool. The robot installed on the beam is responsible for grinding the upper surface and vertical inner cavity of the casting, and the robot installed on the column is responsible for grinding the side elevation and horizontal inner cavity of the casting;

[0051] Place large castings on the workbench of the gantry machine tool, divide the castings into several units, and polish each unit separately;

[0052] The workbench of the gantry machine tool is controlled by the program to drive the casting to move the corresponding distance, and the casting unit to be polished is moved to the robot work area;

[0053] When the grinding robot is located in the unit that needs to be polished, directly drag the robot to teach, and perform offline programming for the casting with the 3D di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com