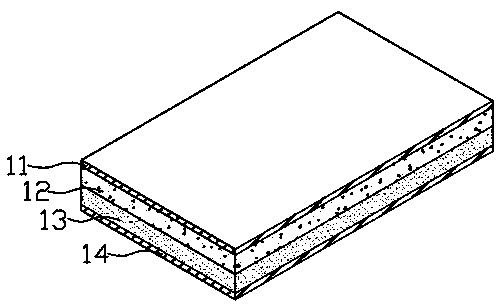

Multi-layer environment-friendly shaving board processing technique

A processing technology and technology of particle board, which is applied in the direction of wood processing equipment, pretreatment of molding materials, manufacturing tools, etc., can solve the problems of human injury and high formaldehyde content of particle board, so as to avoid mosquito harassment, promote human health, and realize flame retardancy effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

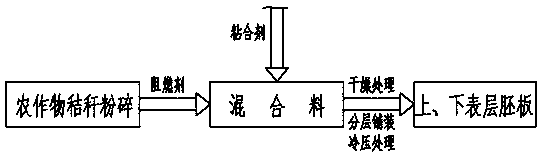

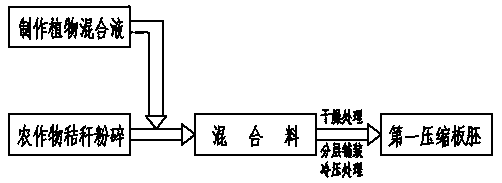

[0048] S1. Fabrication of upper and lower surface panels

[0049] A. First weigh the excess straw particles, and crush the weighed straw particles into powder through a pulverizer, pass through a 80X80 mesh sieve, weigh 10 parts of the sieved straw powder and add it to the mixing box, add 0.1 Parts of water are mixed and stirred evenly;

[0050] B. Add 0.2 part of tributyl phosphate, 0.1 part of triazine and its compound, 0.2 part of chlorobromomethane and octabromodiphenyl chloride into the mixing box, mix to make a flame retardant, and prepare the flame retardant Agent, join in the mixture in step A, mix and stir;

[0051] C. After fully stirring, add 1 part of urea-formaldehyde resin or phenolic resin and mix and stir;

[0052] D. After fully stirring evenly, pass the obtained mixture through a granule forming machine to make particles with a diameter of 3mm-5mm, sieve through machinery, remove larger particles, and dry the filtered particles to obtain water-containing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com