Preparation method of microbial flocculant complex and application of microbial flocculant complex in water treatment field

A microbial flocculant and flocculant technology, which is applied in the field of water treatment, can solve the problems of low research efficiency of microbial flocculants, lack of wide application, single treatment object, etc., to achieve improved dehydration efficiency, simple use method, and high removal rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

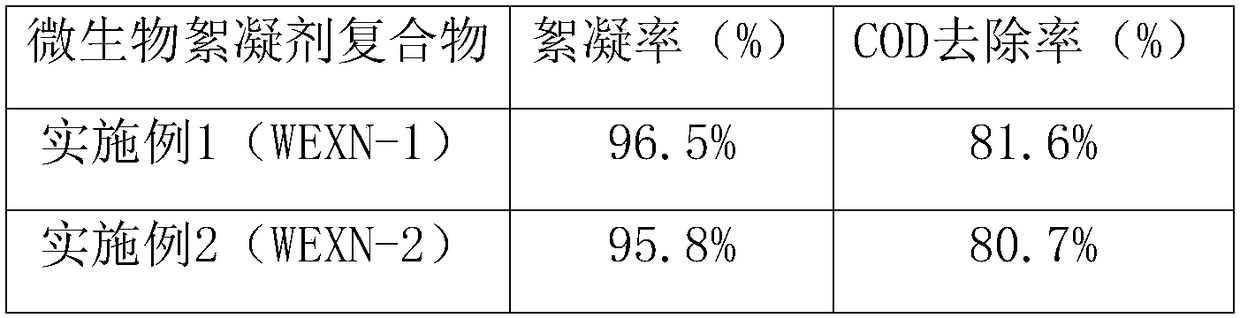

Embodiment 1

[0034] A microbial flocculant compound, the flocculant is composed of a microbial flocculant mixture and a natural polymer modified flocculant, and the compounding method is to combine 75 parts of the microbial flocculant mixture with 25 parts of the natural polymer modified flocculant Dissolve in water, stir at 120rpm for 35min, let it stand still, collect the precipitate by centrifugation, and dry it in vacuum at a temperature of 55°C to obtain the microbial flocculant complex WEXN-1.

[0035] The microbial flocculant mixture includes 25 parts of flocculants fermented by Rhodococcus erythropolis ATCC 10543, 10 parts of flocculants fermented by Bacillus licheniformis CGMCC 1.6510, 5 parts of flocculants fermented by Streptomyces parvum CGMCC 4.5927, fermented by Geotrichum candidum CGMCC 2.1320 15 parts of flocculants were obtained, and 20 parts of flocculants were obtained by fermenting Cocephalus racemosa CGMCC 3.3737.

[0036] The preparation method of each described micro...

Embodiment 2

[0054] A microbial flocculant compound, the flocculant is compounded by a microbial flocculant mixture and a natural polymer modified flocculant, and the compounding method is to combine 65 parts of the microbial flocculant mixture with 35 parts of the natural polymer modified flocculant Dissolve in water, stir at 110rpm for 40min, let it stand still, collect the precipitate by centrifugation, and dry it in vacuum at a temperature of 56°C to obtain the microbial flocculant complex WEXN-2.

[0055] The microbial flocculant mixture includes 20 parts of flocculants fermented by Rhodococcus erythropolis ATCC 10543, 5 parts of flocculants fermented by Bacillus licheniformis CGMCC 1.6510, 5 parts of flocculants fermented by Streptomyces parvum CGMCC 4.5927, fermented by Geotrichum candidum CGMCC 2.1320 10 parts of flocculants were obtained, and 25 parts of flocculants were obtained by fermentation of Cocephalus racemosa CGMCC 3.3737.

[0056] The preparation method of each described...

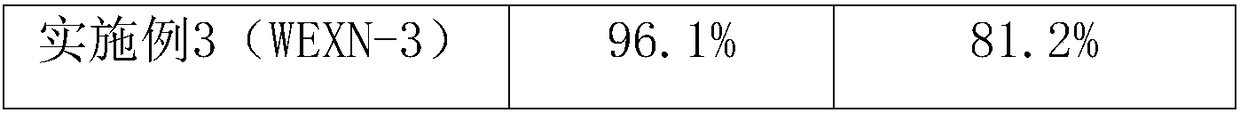

Embodiment 3

[0074] A microbial flocculant compound, the flocculant is compounded by a microbial flocculant mixture and a natural polymer modified flocculant, and the compounding method is to combine 80 parts of the microbial flocculant mixture with 20 parts of the natural polymer modified flocculant Dissolve in water, stir at 100rpm for 40min, let it stand still, collect the precipitate by centrifugation, and dry it in vacuum at a temperature of 55°C to obtain the microbial flocculant complex WEXN-3.

[0075] The microbial flocculant mixture includes 30 parts of flocculants fermented by Rhodococcus erythropolis ATCC 10543, 10 parts of flocculants fermented by Bacillus licheniformis CGMCC 1.6510, 5 parts of flocculants fermented by Streptomyces parvum CGMCC 4.5927, fermented by Geotrichum candidum CGMCC 2.1320 10 parts of flocculants were obtained, and 25 parts of flocculants were obtained by fermentation of Cocephalus racemosa CGMCC 3.3737.

[0076] The preparation method of each describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com