White cement produced by utilizing industrial waste residues and preparation method thereof

A technology for white cement and industrial waste residue, applied in the field of environmentally friendly cement, can solve problems such as the production of white cement products from waste residue and alkali residue, and achieve the effects of improving the strength performance of white cement, reducing production costs, and having strong thermal insulation and moisture resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

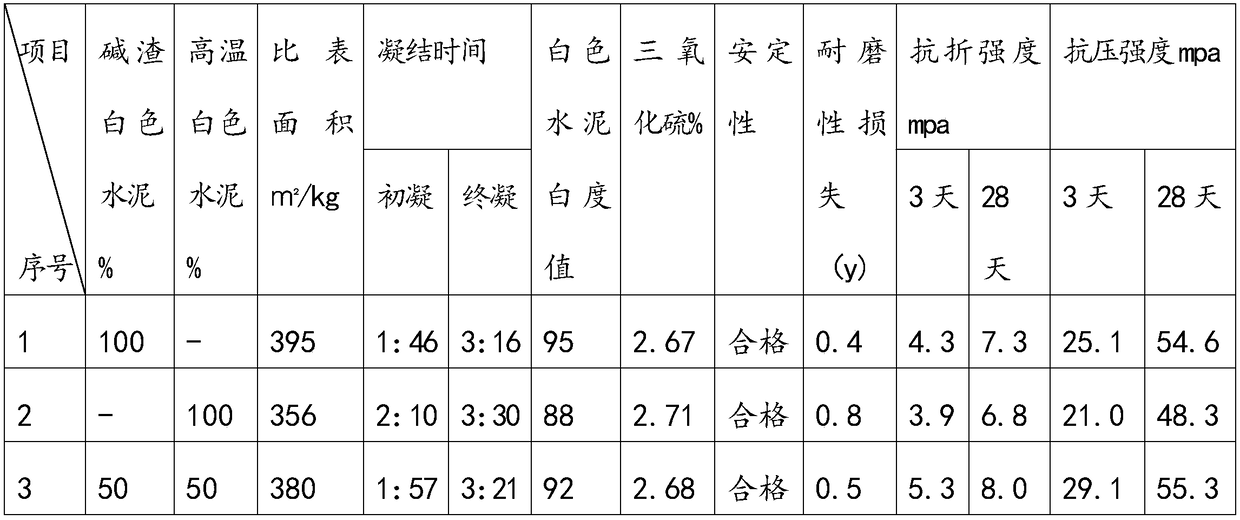

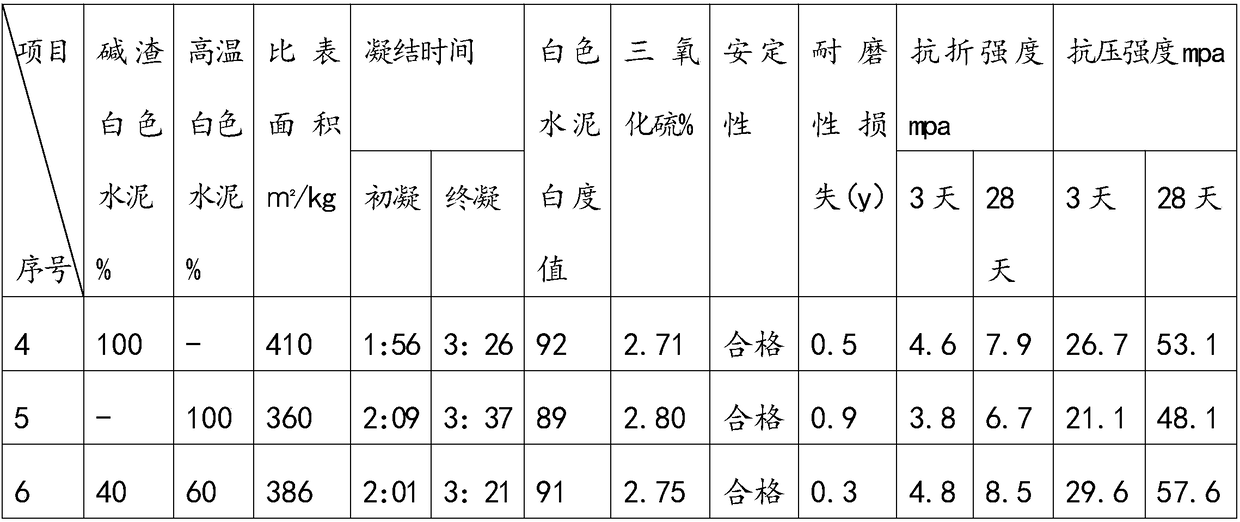

Examples

Embodiment Construction

[0013] The present invention is a method for making white cement products from alkali slag, and mainly uses a more suitable seed powder as an auxiliary raw material. The specific method includes the following steps:

[0014] A. Raw material preparation: the main raw material is the alkali slag discharged from the industrial production stone soda factory minus the free water as required, and the auxiliary raw material is the waste slag and seed powder discharged from the chemical industry;

[0015] B. Ingredients: the alkali slag is calculated as 95-98% by weight percentage, and the ratio of seedling powder as 2-5% by weight percentage is calculated as 100% raw materials to be mixed into a mixture;

[0016] Such as example 1, get alkali slag and calculate by weight percentage to be 95%, and seed powder is calculated by weight percentage to be 5%;

[0017] For example 2, get the alkali slag and calculate it as 98% by weight percentage, and the seed powder is calculated as 2% by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com