Early strength type emulsified asphalt cold recycled mixture and preparation method thereof

A technology for cold recycling mixture and emulsified asphalt, which is applied in the field of road materials, can solve the problems of reducing the low temperature performance of the mixture, the high price of early-strength cement, and increasing the operating cost, and achieves the advantages of improving early strength, facilitating promotion and implementation, and improving strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

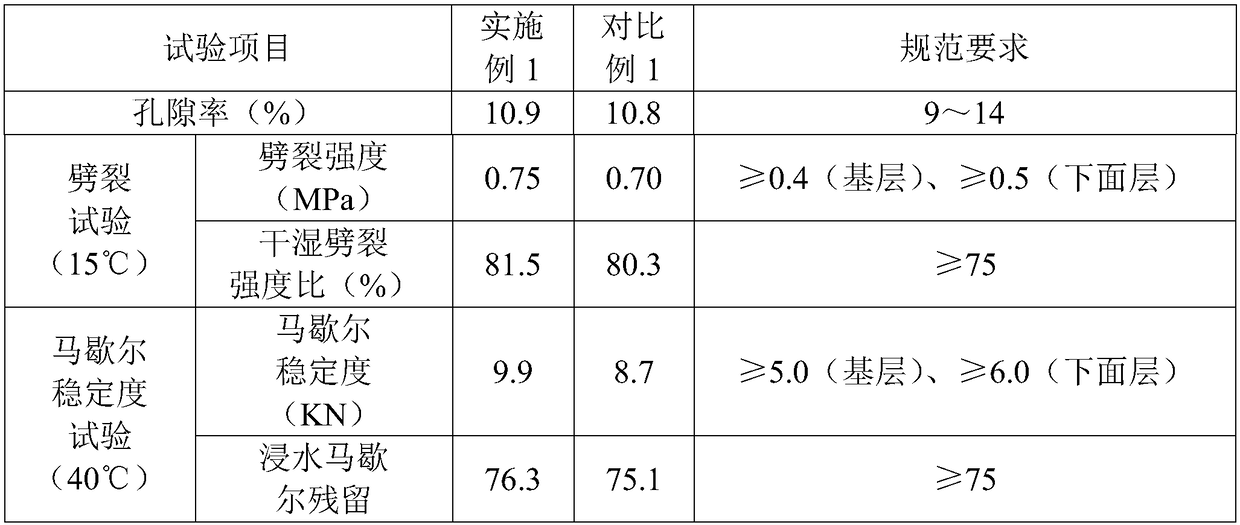

Examples

Embodiment 1

[0052] Example 1. Preparation of early-strength emulsified asphalt cold recycled mixture

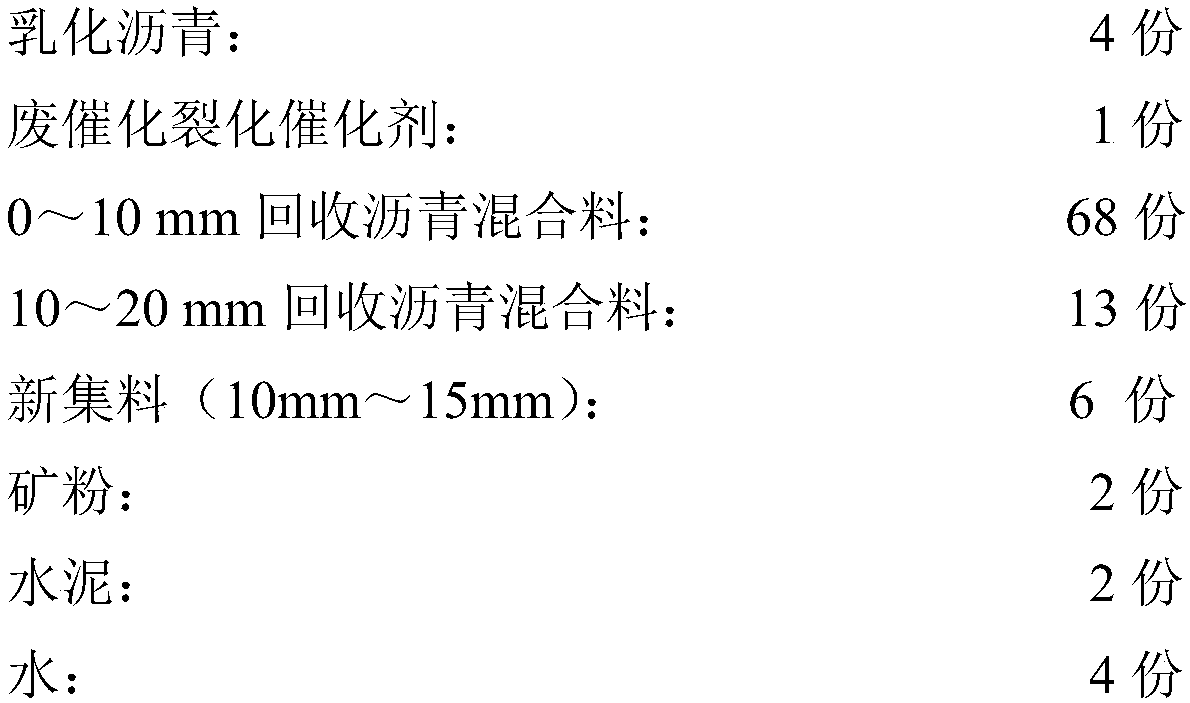

[0053] 1. Formula

[0054] In terms of parts by mass, the early-strength emulsified asphalt cold recycled mixture in this example consists of the following components:

[0055]

[0056] 2. Preparation method

[0057] Prepare early-strength emulsified asphalt cold recycled mixture according to the following steps:

[0058] (1) According to the above formula, weigh each raw material and set aside. Among them, the spent catalytic cracking catalyst is pre-heated to 120°C to remove the moisture in it, and after cooling to normal temperature, it is weighed for later use; the new aggregate is pre-heated to 120°C, and the moisture in it is removed, and after cooling to normal temperature, it is weighed for later use. .

[0059] (2) Mix recycled asphalt mixture, new aggregate, mineral powder, cement and spent catalytic cracking catalyst, stir for 10s (rotating speed: 100 rpm), add water, a...

Embodiment 2

[0073] Example 2. Preparation of early-strength emulsified asphalt cold recycled mixture

[0074] 1. Formula

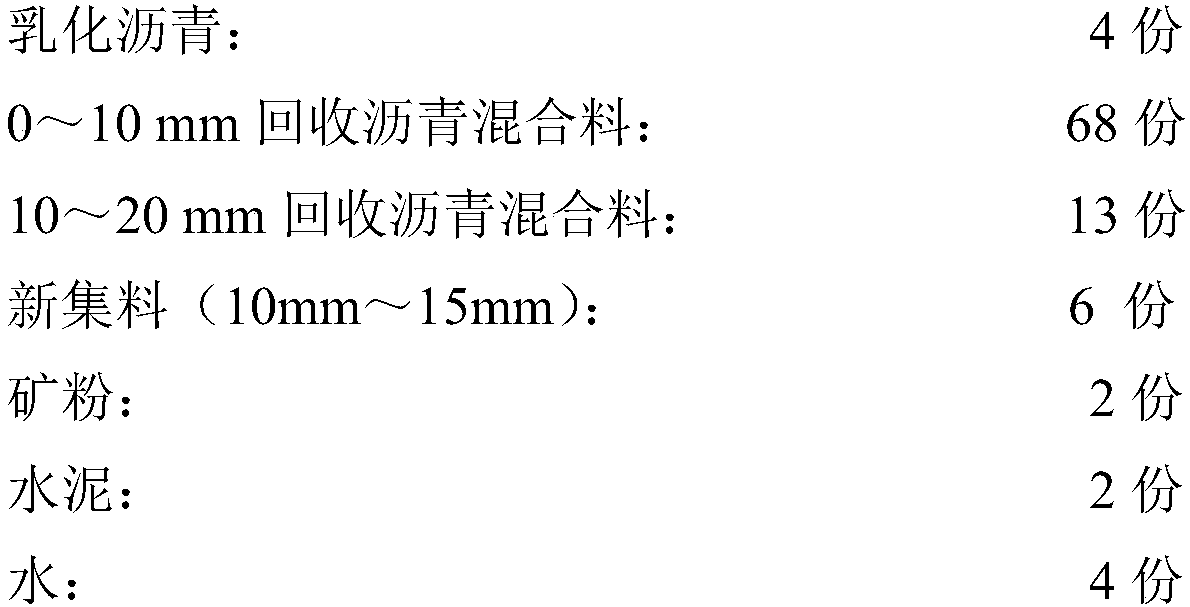

[0075] In terms of parts by mass, the early-strength emulsified asphalt cold recycled mixture in this example consists of the following components:

[0076]

[0077] 2. Preparation method

[0078] Prepare early-strength emulsified asphalt cold recycled mixture according to the following steps:

[0079] (1) According to the above formula, weigh each raw material and set aside. Wherein, the treatment of spent catalytic cracking catalyst and new aggregate is the same as that of Example 1.

[0080] (2) Mix recycled asphalt mixture, new aggregate, mineral powder, cement and spent catalytic cracking catalyst, stir for 10s (rotating speed: 100 rpm), add water, and stir for 30 seconds (rotating speed: 120 rpm).

[0081] (3) Add emulsified asphalt to the material obtained in step (2), and stir for 60 seconds (rotating speed is 120 rpm). The properties of the emulsified a...

Embodiment 3

[0094] Example 3, preparation of early-strength emulsified asphalt cold recycled mixture

[0095] 1. Formula

[0096] In terms of parts by mass, the early-strength emulsified asphalt cold recycled mixture in this example consists of the following components:

[0097]

[0098]

[0099] 2. Preparation method

[0100] Prepare early-strength emulsified asphalt cold recycled mixture according to the following steps:

[0101] (1) According to the above formula, weigh each raw material and set aside. Wherein, the treatment of spent catalytic cracking catalyst and new aggregate is the same as that of Example 1.

[0102] (2) Mix recycled asphalt mixture, new aggregate, mineral powder, cement and spent catalytic cracking catalyst, stir for 10s (rotating speed: 100 rpm), add water, and stir for 30 seconds (rotating speed: 120 rpm).

[0103] (3) Add emulsified asphalt to the material obtained in step (2), and stir for 60 seconds (rotating speed is 120 rpm). The properties of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com