Tert-butyl asymmetric alpha-diimine nickel complex for preparation of ultrahigh-molecular-weight polyethylene elastomers and preparation method and application of tert-butyl asymmetric alpha-diimine nickel complex

A nickel complex, nickel diimide technology, applied in nickel organic compounds, compounds containing elements of Group 8/9/10/18 of the periodic table, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

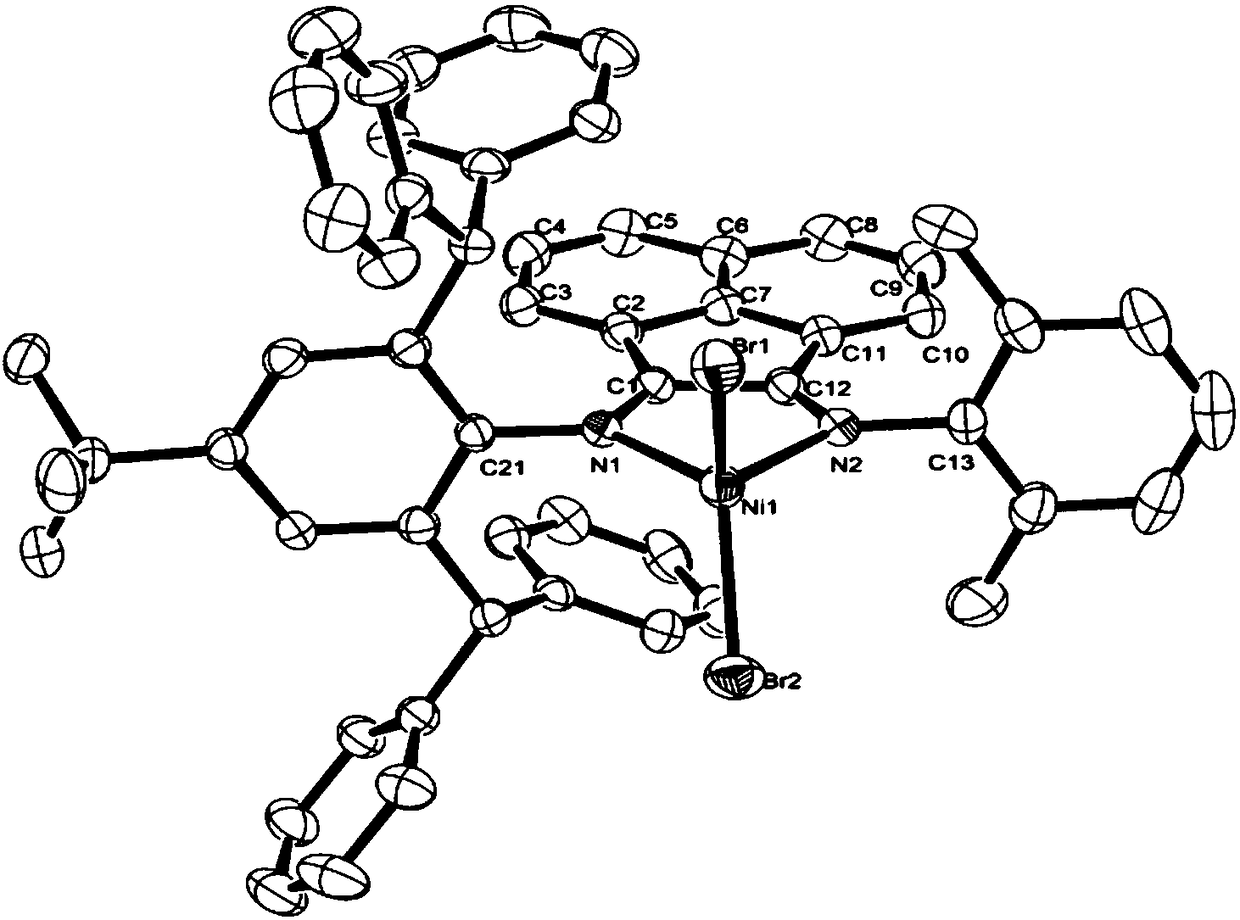

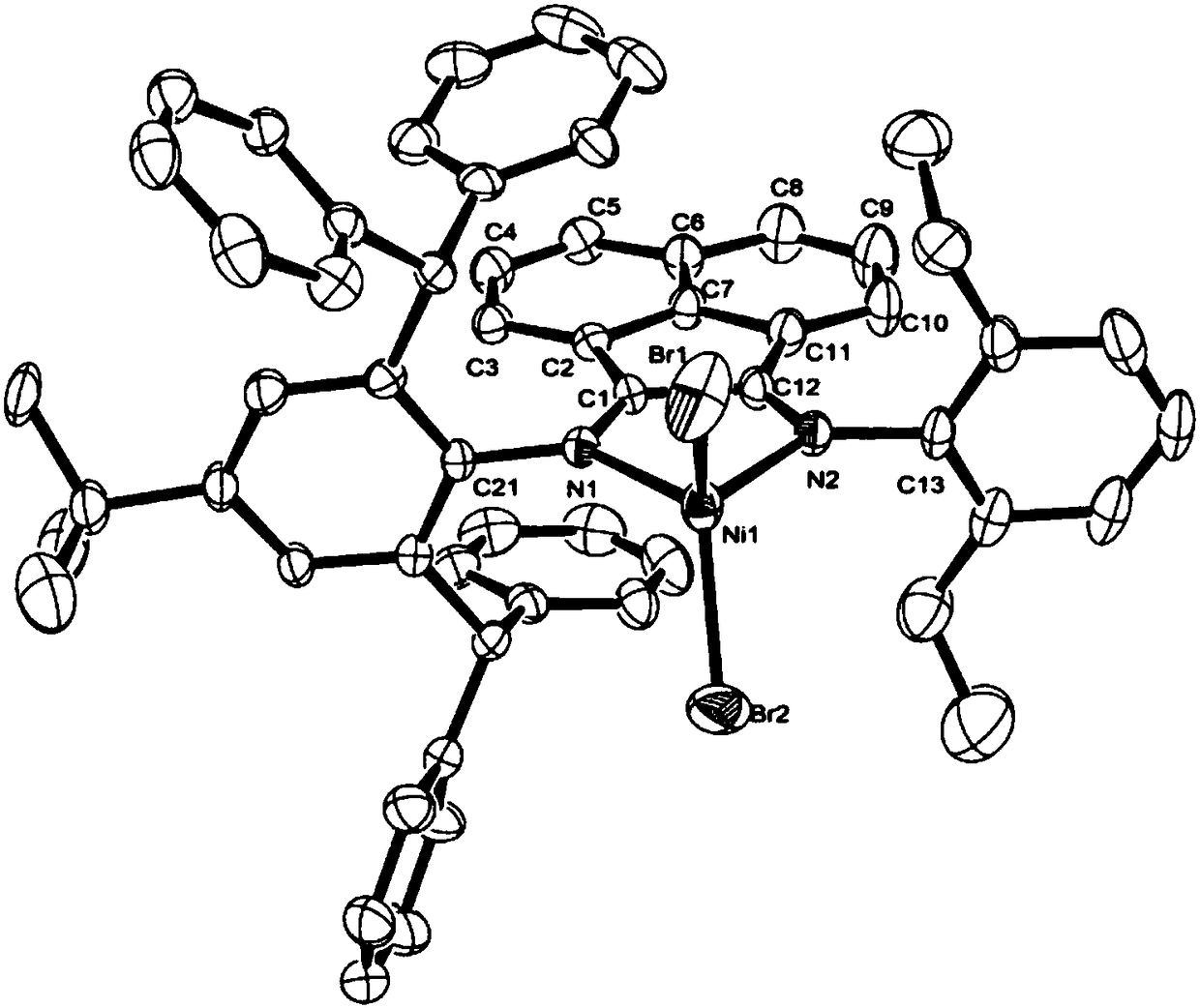

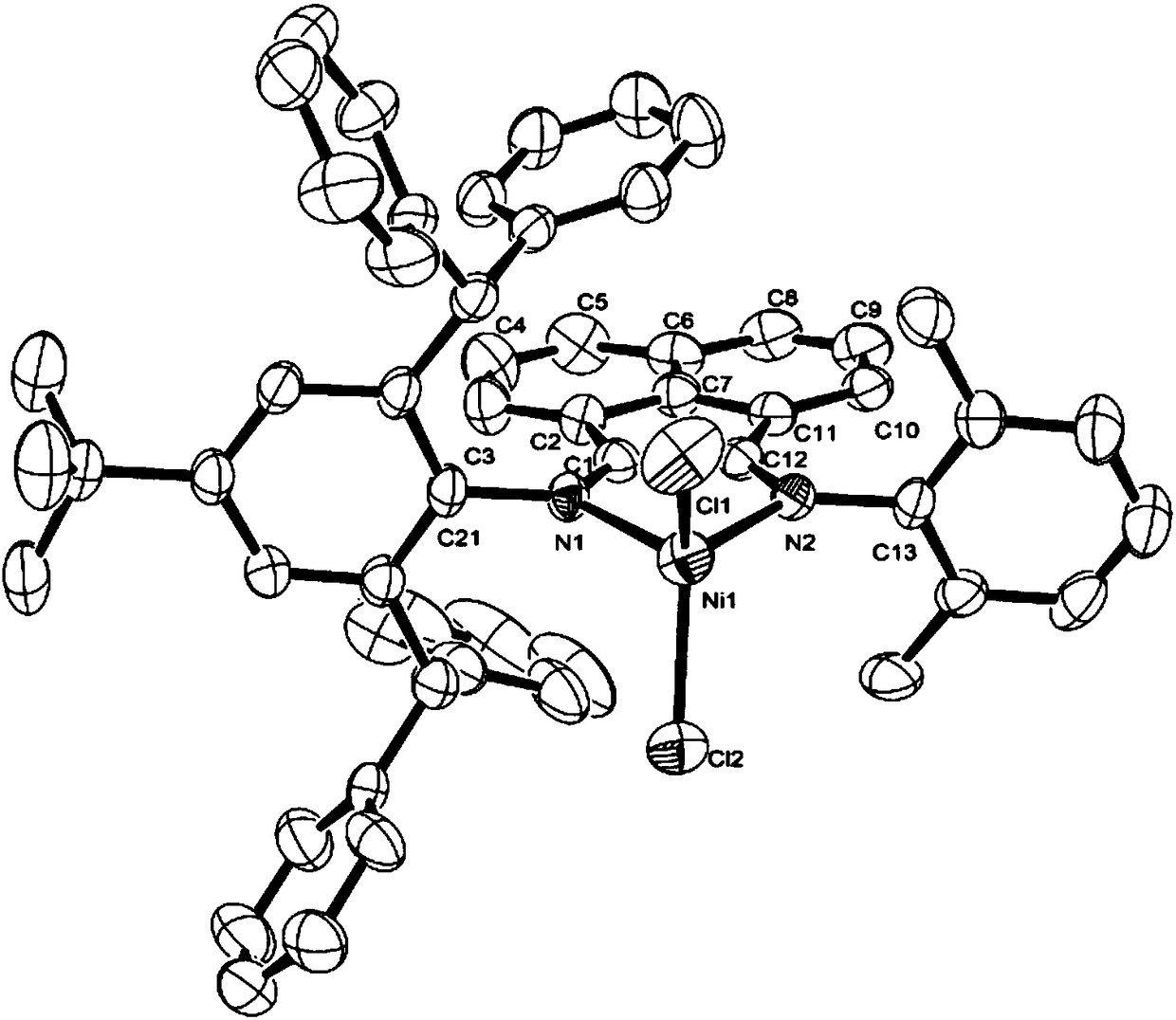

Image

Examples

Embodiment 1

[0125] Preparation of 2-(2,6-bis(diphenylmethyl)-4-tert-butylaniline)acenaphthenone represented by formula (V).

[0126] Add the amount of catalyst (1.25g) to a solution of 2,6-bis(diphenylmethyl)-4-tert-butylaniline (9.63g, 20mmol) and acenaphthenedione (4.00g, 22mmol) in toluene (150mL) P-toluenesulfonic acid, reflux for 5h. The solvent is removed, and the residue is subjected to silica gel column chromatography with a mixed solvent of ethyl acetate and petroleum ether in a volume ratio of 1:50. The elution fraction is detected through a thin-layer silica gel plate. The developing solvent is the volume of petroleum ether and ethyl acetate. The third fraction is collected for the mixed solvent with a ratio of 10:1 and the solvent is removed to obtain an orange solid. Yield: 70%. Melting point: 186-188°C.

[0127] The structure confirmation data is as follows:

[0128] FT-IR(KBr,cm -1 ): 3059(w), 2958(w), 1727(ν(C=O)m), 1657(ν(C=N)m), 1598(s), 1582(s), 1492(s), 1456 (m), 1332(s)...

Embodiment 2

[0133] Preparation of 1-(2,6-dimethylaniline)-2-(2,6-bis(diphenylmethyl)-4-tert-butylaniline)acenaphthene [L1] represented by formula (II), wherein R 1 Is methyl, R 2 Is hydrogen.

[0134] Toluene (2,6-bis(diphenylmethyl)-4-tert-butylaniline)acenaphthene (1.00g, 1.55mmol) and 2,6-dimethylaniline (0.2g, 1.65mmol) 100mL) Add a catalytic amount of p-toluenesulfonic acid to the solution, and heat to reflux for 10h. The solvent toluene was removed, and the residue was subjected to basic alumina column chromatography with a mixed solvent of ethyl acetate and petroleum ether in a volume ratio of 1:50. The eluted fraction was detected by a thin-layer silica gel plate, the second fraction was collected, and the solvent was removed to obtain an orange solid. Yield: 32%. Melting point: 146-148°C.

[0135] The structure confirmation data is as follows:

[0136] FT-IR(KBr,cm -1 ): 3026(w), 2953(w), 1659(ν(C=N)m), 1631(ν(C=N)m), 1593(s), 1446(s), 1361(w), 1255 (w), 1110(w), 1031(m), 924(s), 8...

Embodiment 3

[0141] Preparation of 1-(2,6-diethylaniline)-2-(2,6-bis(diphenylmethyl)-4-tert-butylaniline)acenaphthene [L2] represented by formula (II), wherein R 1 Is ethyl, R 2 Is hydrogen.

[0142] Toluene (2,6-bis(diphenylmethyl)-4-tert-butylaniline)acenaphthene (1.00g, 1.55mmol) and 2,6-diethylaniline (0.21g, 1.65mmol) 100mL) Add a catalytic amount of p-toluenesulfonic acid to the solution, and heat to reflux for 10h. The solvent toluene was removed, and the residue was subjected to basic alumina column chromatography with a mixed solvent of ethyl acetate and petroleum ether in a volume ratio of 1:50. The eluted fraction was detected by a thin-layer silica gel plate, the second fraction was collected, and the solvent was removed to obtain an orange solid. Yield: 35%. Melting point: 197-199°C.

[0143] The structure confirmation data is as follows:

[0144] FT-IR(KBr,cm -1 ): 3026(w), 2959(w), 1659(ν(C=N)m), 1632(ν(C=N)m), 1593(m), 1447(s), 1361(w), 1257 (m), 1111(m), 1073(m), 923(s), 777...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com