A kind of fluorescent gold nanocluster aggregate and preparation method thereof

A fluorescent gold nano-aggregate technology, applied in the fields of chemistry and material science, can solve the problems affecting the application of fluorescent gold nano-clusters, non-dispersion and non-fluorescence of fluorescent gold nano-clusters, and achieve excellent photobleaching resistance, Excellent photoluminescence properties, large Stokes shift effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

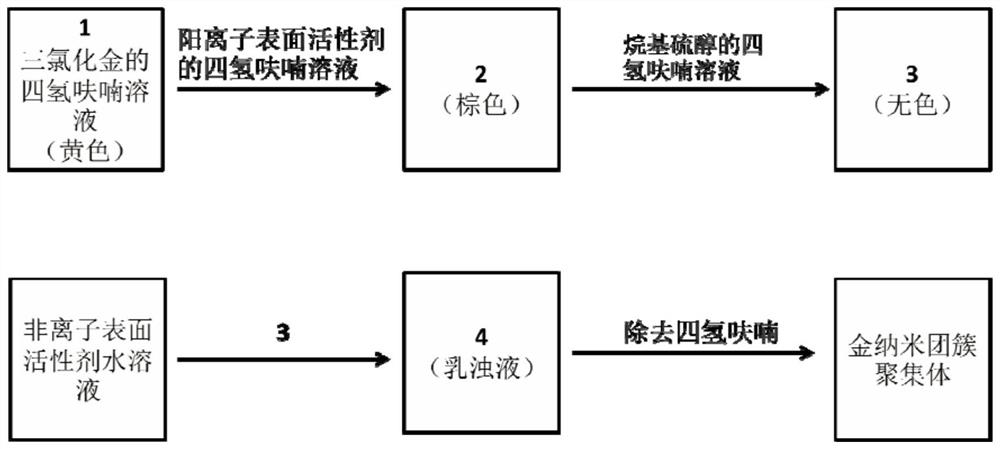

[0025] An aspect of the embodiments of the present invention provides a method for preparing a fluorescent gold nanocluster aggregate, which includes:

[0026] The cationic surfactant and the gold source are mixed and reacted in an organic solvent at 5-35°C to obtain a compound reactant;

[0027] Mixing and reacting the composite reactant with alkylthiol at 5-35°C to obtain an alkylthiol-gold complex solution;

[0028] The alkylthiol-gold complex solution is added into the aqueous solution of the nonionic surfactant to generate fluorescent gold nano cluster aggregates.

[0029] In some typical implementation cases, the preparation method includes:

[0030] Add the organic solution of the cationic surfactant to the organic solution of the gold source and mix and react uniformly at 5-35°C to obtain a complex reactant;

[0031] Slowly add the organic solution of alkylthiol to the composite reactant under vigorous stirring, and mix and react at 5-35°C to obtain the alkylthiol-go...

Embodiment 1

[0058] 1) Add 240 μL of 100 mmol / L tetrahydrofuran solution of didodecyldimethylammonium bromide to 3310 μL of 7.55 mmol / L gold trichloride in tetrahydrofuran under vigorous stirring at 20°C, The color of the solution gradually changed from yellow to brown.

[0059] 2) After 5 minutes, slowly add 180 μL of 500 mmol / L tetrahydrofuran solution of dodecylmercaptan to the solution obtained in 1) dropwise under vigorous stirring. After 10 minutes, the solution gradually becomes colorless.

[0060] 3) Take 100 μL of the above solution, slowly drop it into 900 μL of 20° C. aqueous solution containing 0.001 (volume ratio) Tween 80 under vigorous stirring, and the solution turns milky white.

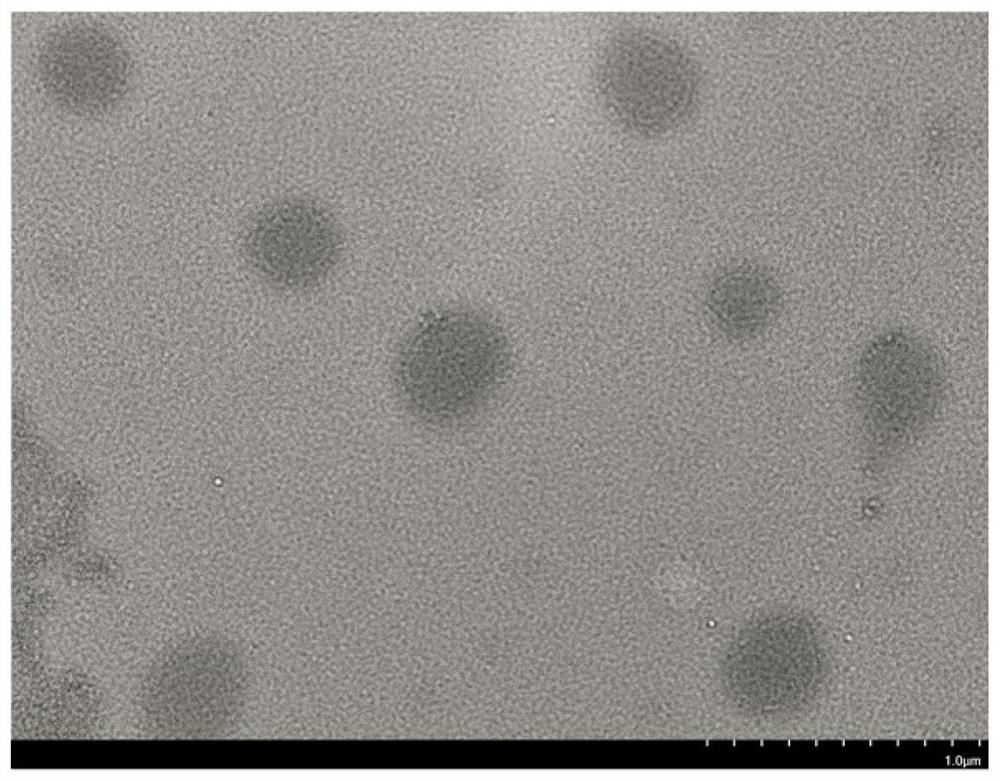

[0061] 4) Add the above emulsion into a dialysis bag with a molecular weight cut-off of 14,000, and dialyze in deionized water at 20°C for 2 days to remove tetrahydrofuran, etc., to obtain an aqueous solution of stably dispersed gold nanocluster aggregates.

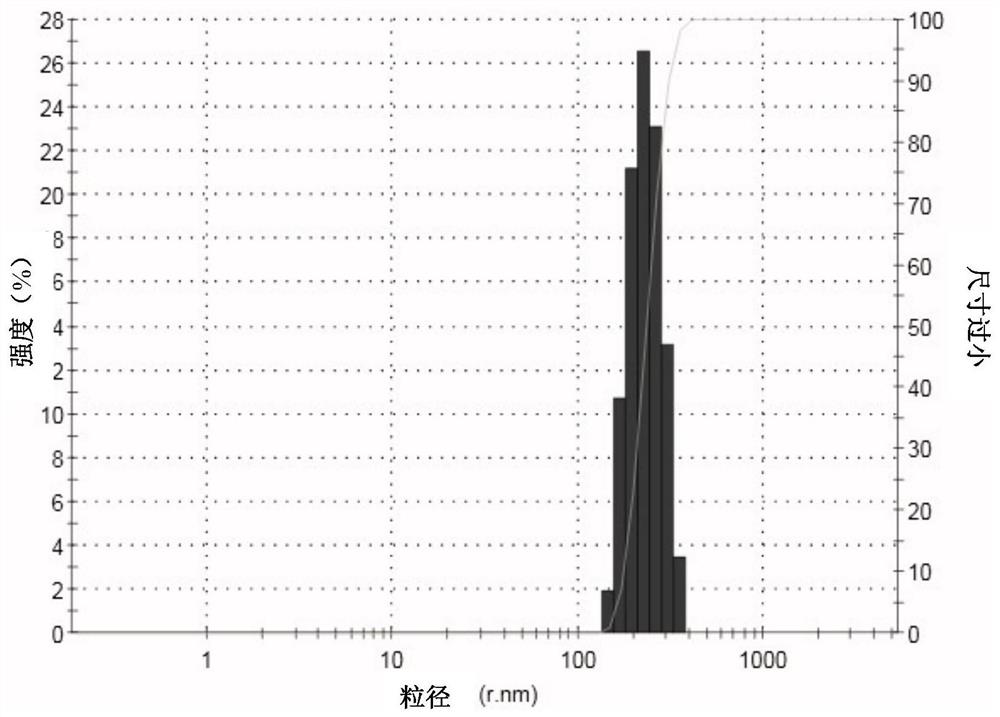

[0062] After testing, the transmissi...

Embodiment 2

[0064] 1) At 5°C, under vigorous stirring, add 240 μL of 100 mmol / L tetrahydrofuran solution of ditetradecyldimethylammonium bromide to 3310 μL of 7.55 mmol / L gold trichloride in tetrahydrofuran solution, The color of the solution gradually changed from yellow to brown.

[0065] 2) After 5 minutes, slowly add 180 μL of a 500 mmol / L tetrahydrofuran solution of undecylmercaptan to the solution obtained in 1) under vigorous stirring. After 10 minutes, the solution gradually becomes colorless.

[0066] 3) Take 100 μL of the above solution, slowly drop it into 900 μL of 5° C. aqueous solution containing 0.001 (volume ratio) Tween 80 under vigorous stirring, and the solution turns milky white.

[0067] 4) Rotating the above emulsion to remove tetrahydrofuran to obtain an aqueous solution of stably dispersed gold nanocluster aggregates.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com