Coating method of curved mirror for concentrated solar module

A concentrating solar energy and curved mirror technology, which is applied in the field of concentrating solar energy, can solve the problems of secondary light and energy loss, increased cost of coating equipment, and difficulty in coating on curved surfaces, so as to avoid secondary light loss, reduce coating difficulty, Conducive to the effect of precision and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

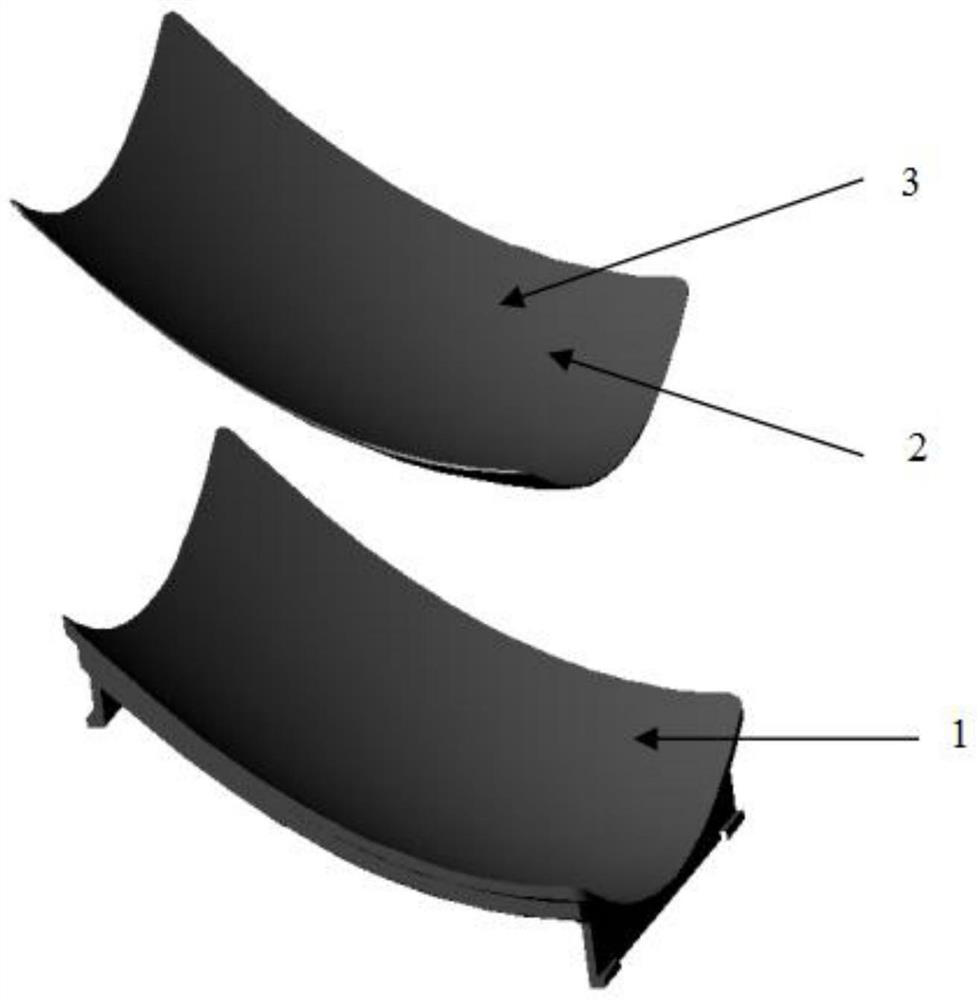

[0030] see figure 1 , the present invention provides a curved mirror for concentrating solar modules, comprising: a curved substrate 1, a film sheet 2, the film sheet 2 is arranged on the concave surface of the curved substrate 1, the film sheet 2 It includes a film 21 , a reflective layer 22 disposed on the film 21 , and an adhesive disposed between the film 21 and the reflective layer 22 . The curved substrate 1 adopts a small-sized free-form surface or a paraboloid. The material of the curved substrate 1 is one of glass, aluminum, plastic or silicon-glass bonding structural material, specifically, the material of the curved substrate 1 is polycarbonate, acrylic, polyethylene terephthalate Alcohol ester or polybutylene terephthalate, more specifically, the material of the curved substrate 1 in this embodiment is acrylic, which is cheap, e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com