Lithium ion battery separator and preparation method thereof

A lithium-ion battery and diaphragm technology, applied in the field of lithium-ion battery diaphragm and its preparation, can solve the problems of poor bonding performance of the diaphragm, achieve improved bonding performance, stable slurry performance, and no change in coating properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

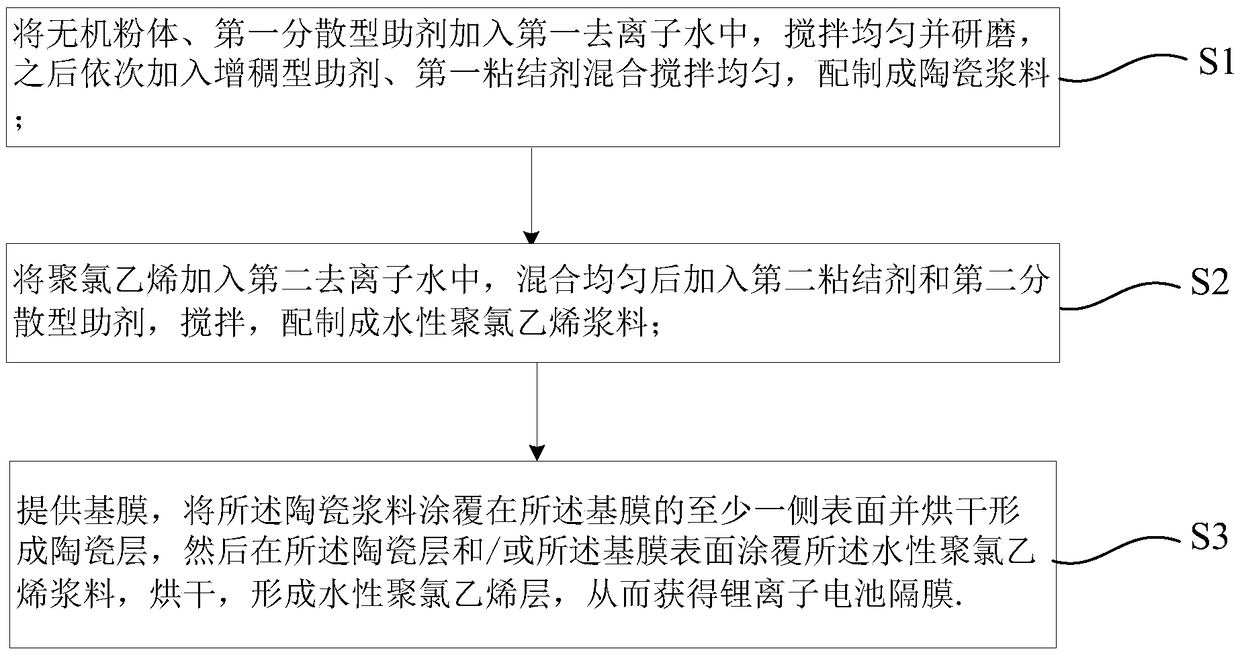

[0035] Such as figure 1 As shown, the present invention provides a kind of preparation method of lithium-ion battery diaphragm, and described preparation method comprises at least:

[0036] S1, adding the inorganic powder and the first dispersing additive into the first deionized water, stirring evenly and grinding, then adding the thickening additive and the first binder in turn, mixing and stirring evenly, and preparing a ceramic slurry;

[0037] S2, adding polyvinyl chloride into the second deionized water, mixing evenly, adding the second binder and the second dispersing auxiliary agent, stirring, and preparing water-based polyvinyl chloride slurry;

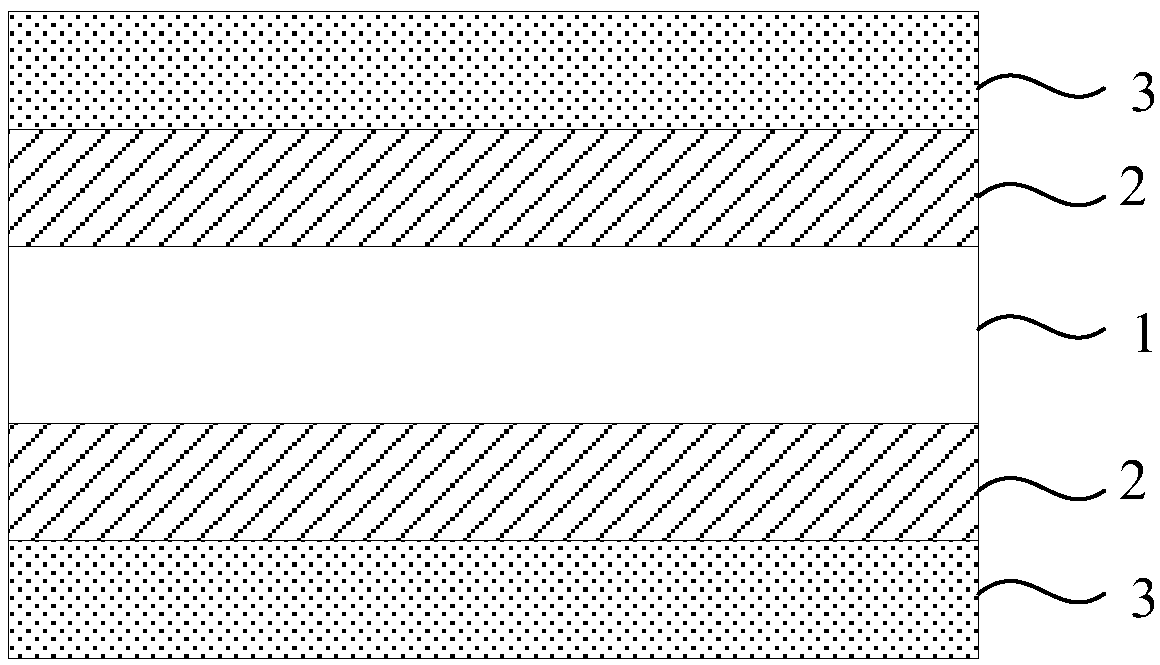

[0038] S3, providing a base film, coating the ceramic slurry on at least one side surface of the base film and drying to form a ceramic layer, and then coating the water-based slurry on the surface of the ceramic layer and / or the base film The polyvinyl chloride slurry is dried to form a water-based polyvinyl chloride layer,...

Embodiment 1

[0062] A. Preparation of water-based slurry: Add 4 parts by mass of dispersing additive and 32 parts by mass of alumina powder into 54 parts by mass of deionized water and stir until completely dispersed and ground, then add 5 parts by mass of thickening type Continue to stir the additives until they are completely dispersed, and finally add 5 parts by mass of adhesive and continue to stir until they are completely mixed to obtain a water-based ceramic slurry; add 20 parts by mass of polyvinyl chloride powder to 60 parts by mass of deionized water and mix well before adding 8 parts by mass of the adhesive and 12 parts by mass of the dispersing additive were stirred evenly until completely mixed to obtain a polyvinyl chloride slurry. The mass ratio of alumina powder to polyvinyl chloride powder is 8:1.

[0063] B. Preparation process of lithium-ion battery ceramic composite diaphragm: Use a coating machine to uniformly coat ceramic slurry and polyvinyl chloride slurry on one si...

Embodiment 2

[0065] A. Preparation of water-based slurry: Add 4 parts by mass of dispersing additive and 32 parts by mass of alumina powder into 54 parts by mass of deionized water and stir until completely dispersed and ground, then add 5 parts by mass of thickening type Continue to stir the auxiliary agent until it is completely dispersed, and finally add 5 parts by mass of adhesive and continue to stir until it is completely mixed to obtain a water-based ceramic slurry; add 60 parts by mass of polyvinyl chloride aqueous solution emulsion to 20 parts by mass of deionized water and mix well before adding 8 parts by mass of the adhesive and 12 parts by mass of the dispersing additive were stirred evenly until completely mixed to obtain a polyvinyl chloride slurry. The mass ratio of alumina powder to polyvinyl chloride in polyvinyl chloride emulsion is 8:1.

[0066] B. Preparation process of lithium-ion battery ceramic composite diaphragm: Use a coating machine to uniformly coat ceramic slu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com