Processing method of active premade cooked beans

A processing method and a technology for prefabricating beans, which are applied in the directions of heating preservation of fruits/vegetables, food preservation, and fresh-keeping of fruits and vegetables, can solve the problems of difficult preservation and low content of functional components, and achieve easy preservation, good antioxidant effect, and expansion The effect of the applicable group

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

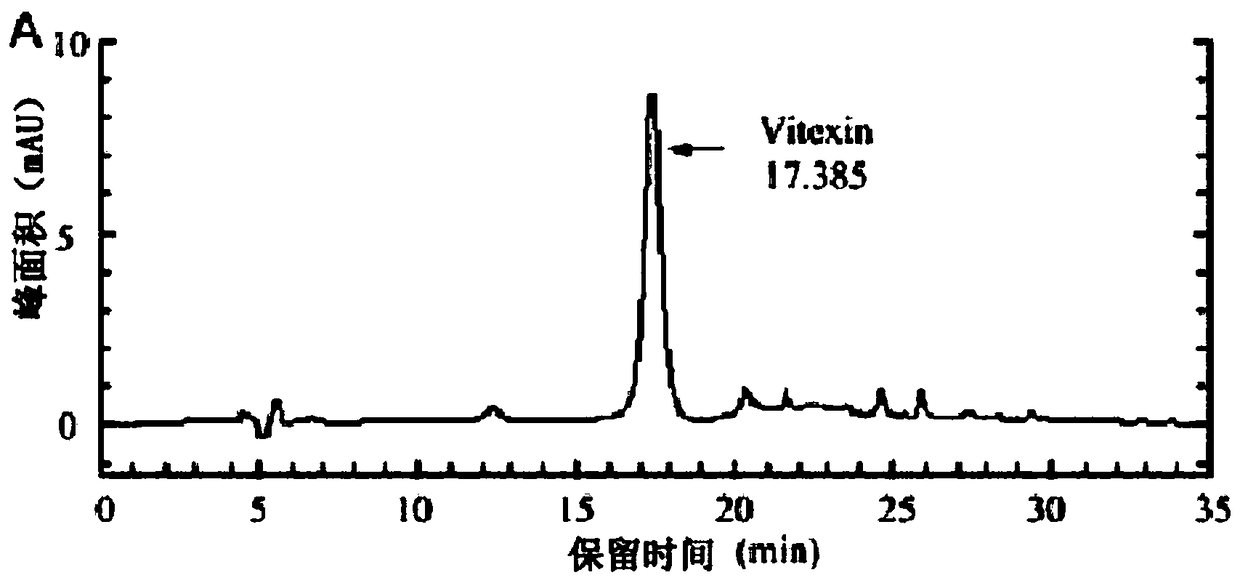

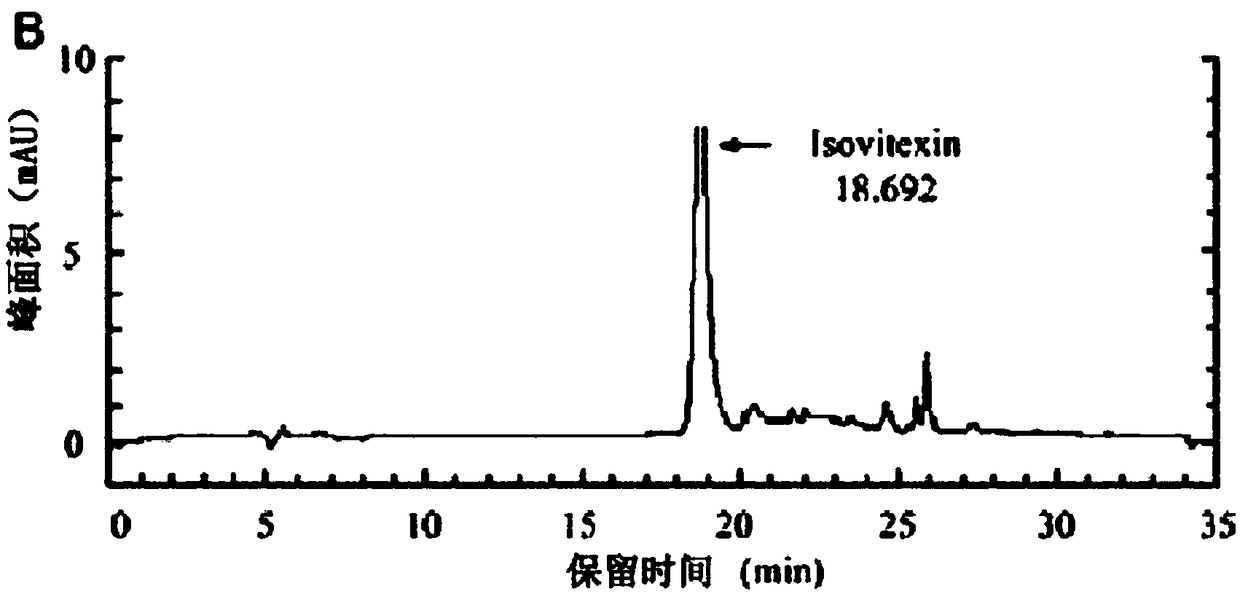

[0032] Preparation of sample solution: Weigh 0.5 g of a sample crushed through a 60-mesh sieve, add 10 ml of 50% ethanol, and extract under reflux in a water bath at 60° C. for 2 h. Extract twice and combine the extract to make up to 10mL.

[0033] Operation steps: Accurately weigh 10.5mg of fully dried gallic acid, dissolve it in distilled water, transfer it to a 100ml volumetric flask to constant volume, and obtain a standard solution with a concentration of 105μg / mL. Accurately pipette 2, 3, 4, 5, 6, 7, 8mL of the above gallic acid standard solution into a 10mL volumetric flask, add 1mL of Folin-ciocalten chromogenic solution respectively, then add 3mL of 1mol / ml sodium carbonate solution and shake well, then Place it at room temperature in the dark for 15 minutes, and finally distill the volume to 10 mL with distilled water, measure the A value at 725 nm, take A as the ordinate, and take the concentration of gallic acid as the abscissa to draw a standard curve. In the sam...

Embodiment 1

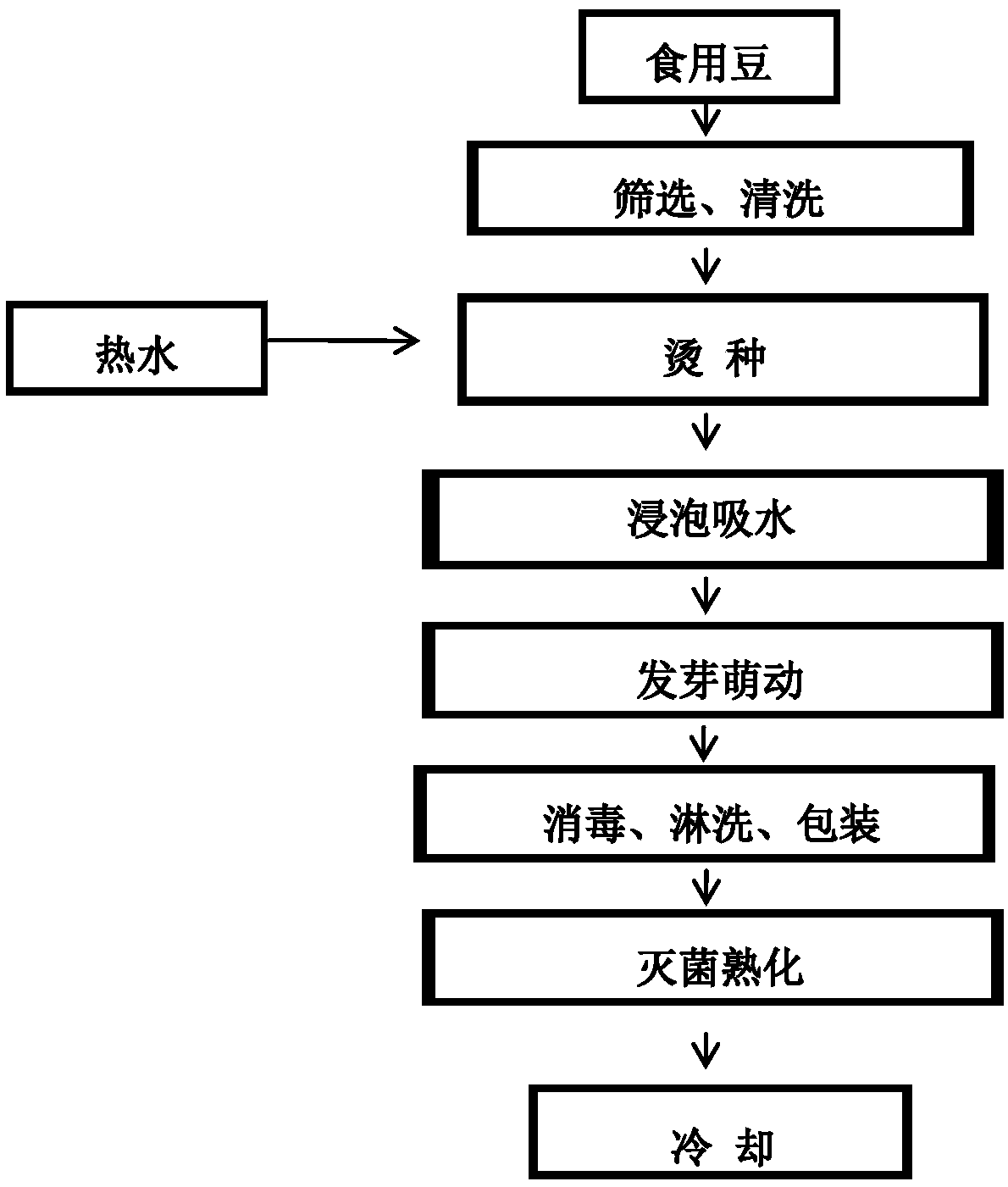

[0052] The processing method of embodiment 1. active prefabricated red bean.

[0053] After the red beans are screened, washed and drained, they are placed in a stainless steel basin and added to hot water at 70°C according to the bean-to-water ratio (mass ratio) of 1:3. After the beans enter the water, the water temperature drops by about 2-5°C. After cooling, it enters into the soaking step immediately, and is placed at room temperature, soaked to absorb water for 20 hours, and the water absorption rate reaches 109.1%.

[0054] The soaked red beans are placed in the special germination equipment XZ60-A bean seedling machine, the germination temperature is 30°C, the germination is cultivated for 8 hours, and the chlorine dioxide disinfectant with a mass concentration of 0.003% is rinsed twice, and then rinsed twice with water , vacuum-packed (50g / bag), and then sprayed and sterilized at 115° C. for 10 minutes to further ripen the red bean to obtain an active prefabricated red...

Embodiment 2

[0055] Embodiment 2. The processing method of active prefabricated mung bean.

[0056] After the mung beans are screened, washed and drained, they are placed in a stainless steel basin and added to hot water at 65°C according to the bean-to-water ratio (mass ratio) of 1:5. , then enter the soaking step, place it at room temperature, soak for 5 hours to absorb water, and the water absorption rate reaches 106.8%.

[0057] The soaked mung beans are placed in the special germination equipment XZ60-A bean seedling machine, the germination temperature is 30°C, the germination is cultivated for 8 hours, and the chlorine dioxide disinfectant with a mass concentration of 0.003% is rinsed twice, and then rinsed twice with water. Vacuum packaging (50g / bag), followed by spray sterilization at 110°C for 10 minutes to further ripen the mung beans to obtain active prefabricated mung bean products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com