Method for processing American ginseng black ginseng by taking fresh American ginseng as raw material

A technology of American ginseng and raw materials, which is applied in the field of processing American ginseng black ginseng, can solve the problems of loss of active ingredients, difficulty in ultrasonication, poor product quality, etc., and achieve the effects of increased conversion rate of rare glycosides, significant technical effects, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for processing American ginseng black ginseng with fresh American ginseng as raw material, the steps are as follows:

[0027] (1) Wash 500 grams of 5-year-old fresh American ginseng (Tonghuo) and dry the epidermis.

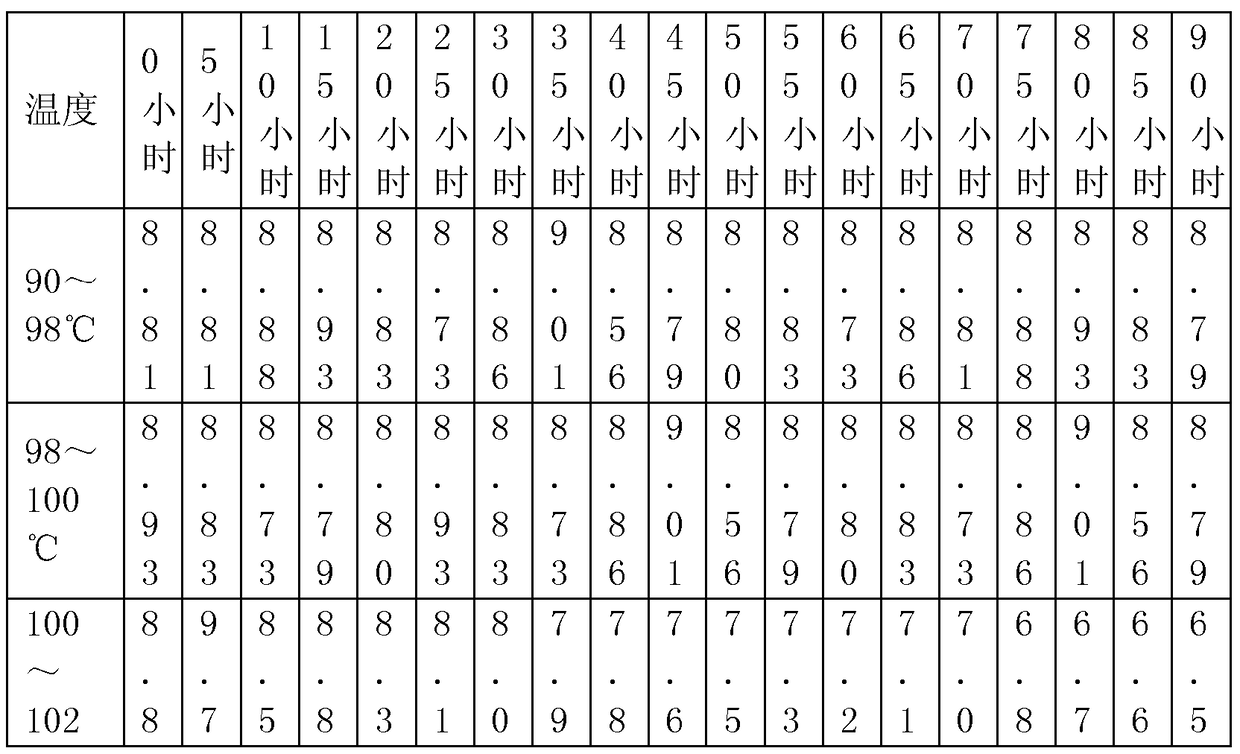

[0028] (2) Put it in a steamer and heat it to 98-100°C.

[0029] (3) Keep the temperature of the steamer at 98-100°C for 56 hours.

[0030] (4) Cut off the steam source, and open the steamer when the temperature in the steamer drops to 52°C.

[0031] (5) Cool the steamed American ginseng (not hot), put it in a drying room at 50-55°C and dry it until the moisture content is 11.70%, take it out, and finish the product.

[0032] After testing, the content of ginsenoside Rg3 in American ginseng and black ginseng is 6.8835 mg / g. The content of ginsenoside Rg5 is 6.5132mg / g.

Embodiment 2

[0034] A method for processing American ginseng black ginseng with fresh American ginseng as raw material, the steps are as follows:

[0035] (1) Wash 500 grams of 5-year-old fresh American ginseng (Tonghuo) and dry the epidermis.

[0036] (2) Put it in a steamer and heat it to 98-100°C.

[0037] (3) Keep the temperature of the steamer at 98-100°C for 58 hours.

[0038] (4) Cut off the steam source, and open the steamer when the temperature in the steamer drops to 53°C.

[0039] (5) Cool the steamed American ginseng (not hot), put it in a drying room at 50-55°C and dry it until the water content is 11.6%, take it out, and the finished product.

[0040] After testing, the content of ginsenoside Rg3 in American ginseng and black ginseng is 6.7070mg / g. The content of ginsenoside Rg5 is 6.5221mg / g.

Embodiment 3

[0042] A method for processing American ginseng black ginseng with fresh American ginseng as raw material, the steps are as follows:

[0043] (1) Wash 500 grams of 5-year-old fresh American ginseng (Tonghuo) and dry the epidermis.

[0044] (2) Put it in a steamer and heat it to 98-100°C.

[0045] (3) Keep the temperature of the steamer at 98-100°C for 60 hours.

[0046] (4) Cut off the steam source, and open the steamer when the temperature in the steamer drops to 52.5°C.

[0047] (5) Cool the steamed American ginseng (not hot), put it in a drying room at 50-55°C and dry it until the water content is 11.3%, take it out, and finish the product.

[0048] After testing, the content of ginsenoside Rg3 in American ginseng and black ginseng is 7.0121 mg / g. The content of ginsenoside Rg5 is 6.4463mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com