Section bar automation production line

An automated production line and profile technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the inability to realize automatic production of profile cleaning processes, large storage areas for semi-finished profiles, discontinuity of production lines, etc. problems, achieve the effect of realizing unmanned and dust-free operation, improving production continuity, reducing handling time and storage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

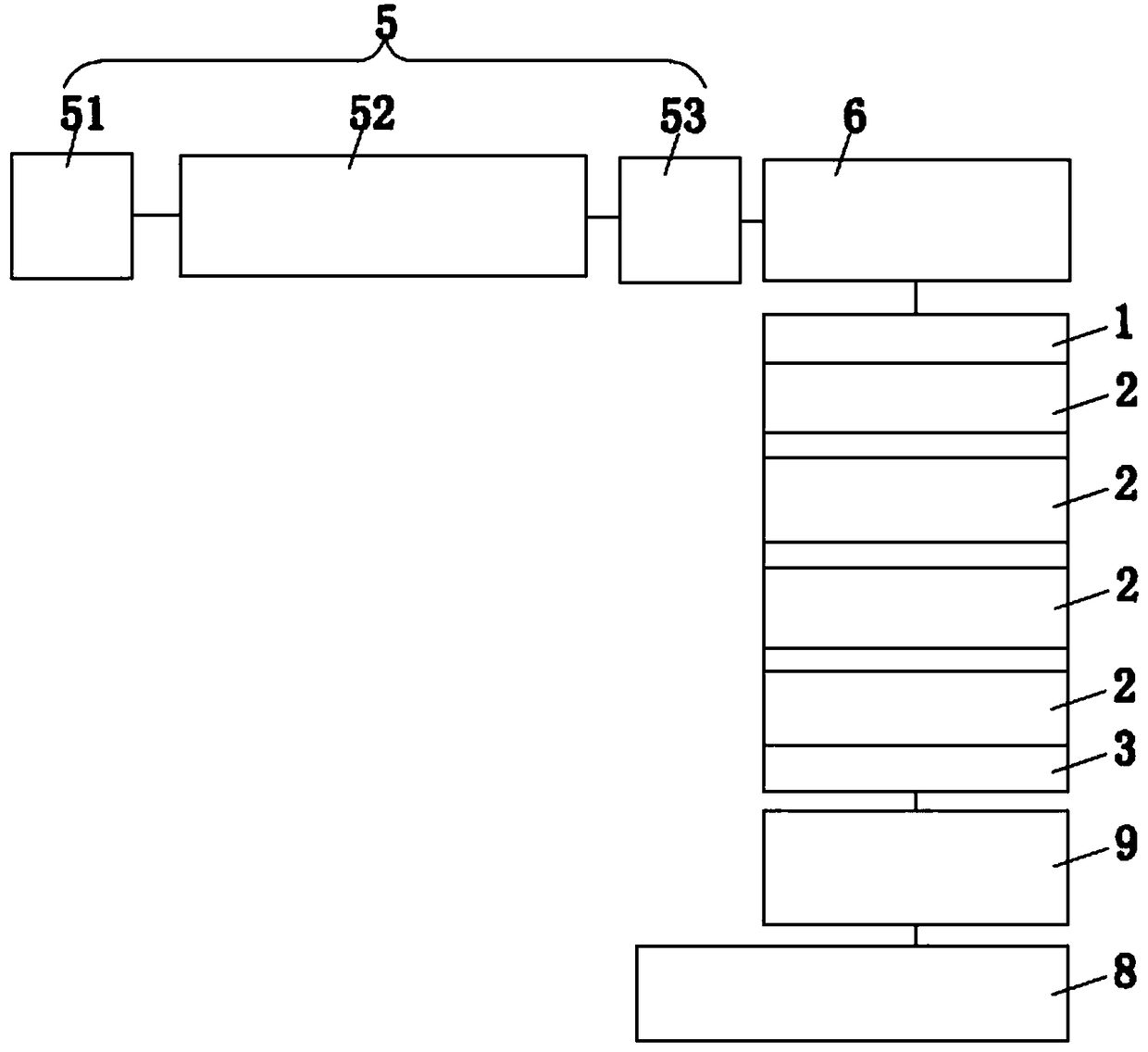

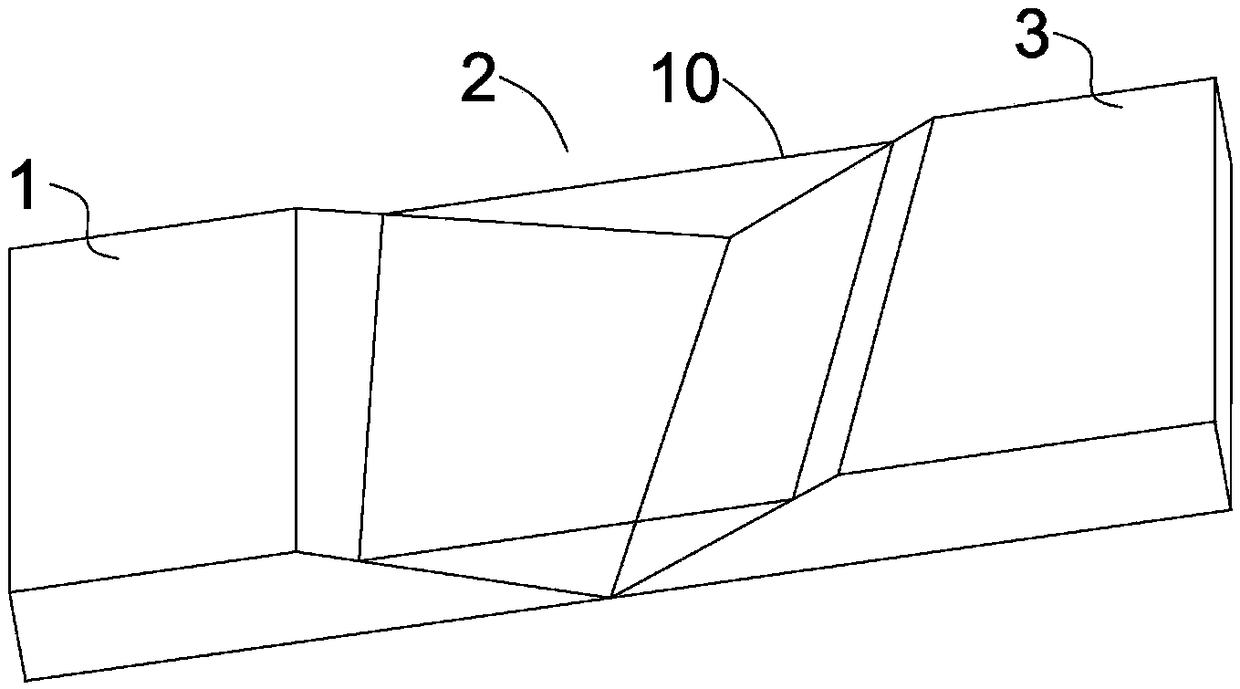

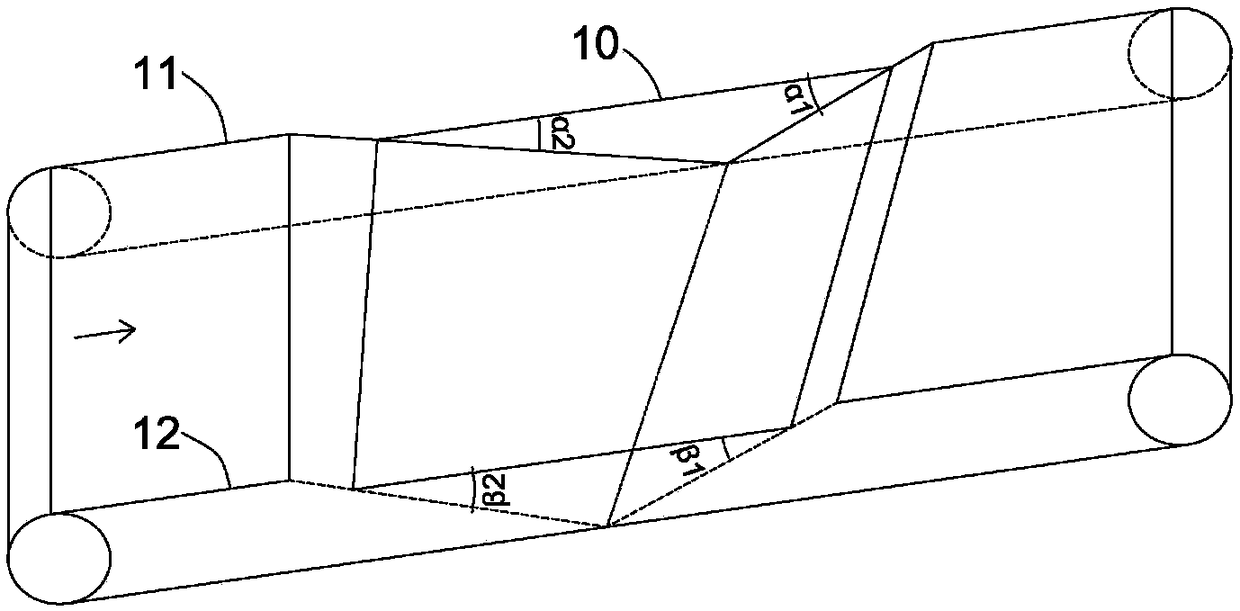

[0035] An automatic profile production line, comprising a forming station 5, a surface brightening station 6, a cleaning station 7 and a packaging station 8 arranged in sequence, and the profiles formed by the forming station 5 pass through the surface brightening station 6 continuously , cleaning station 7 and packaging station 8; between each station, the continuous passage of profiles is usually achieved by setting a conveying and transferring mechanism; such a conveying and transferring mechanism has many technical solutions in the prior art, and will not be described here Discussion; in this embodiment, the cleaning station 7 includes a feeding area 1, a cleaning tank 2, a discharging area 3, and a conveying mechanism for obliquely taking the profile away from the liquid surface of the cleaning tank 2; the conveying mechanism It is a structure used to make the profiles pass through the feeding area 1, the cleaning pool 2 and the discharging area 3 sequentially along the sm...

Embodiment 2

[0051] An automatic profile production line for producing galvanized steel pipes, comprising a forming station 5, a surface brightening treatment station 6, a cleaning station 7, a surface coloring treatment station 9 and a packaging station 8 arranged in sequence. If the steel pipe is a seamless pipe, the forming station 5 adopts hot rolling or cold rolling to make the seamless steel pipe; if the steel pipe is a welded pipe, the forming station 5 can use straight seam welding or spiral welding to make the welded pipe. The formed steel pipe enters the stress relief station and heat treatment is used to eliminate the residual stress in the steel pipe and prolong its service life.

[0052] Surface brightening station 6 includes grinding and polishing stations. Grinding and polishing of steel pipes can be done with grinding wheels or shot peening to improve the fatigue strength, wear resistance and roughness of aluminum alloy pipes.

[0053] A cutting station can be set between t...

Embodiment 3

[0059] The conveying mechanism of the cleaning station 7 includes a first boom 31 and a second boom 32 arranged side by side, and a transmission mechanism 33 for driving the two booms through the feeding area 1, the cleaning pool 2 and the discharging area 3 in sequence; The two booms are suspended above the feeding area 1, the cleaning pool 2 and the discharging area 3, the upper ends are respectively connected to the transmission mechanism 33, and the lower ends are freely extended downwards and are respectively provided with a clamping mechanism 34 for clamping profiles, The middle part is provided with a length adjusting mechanism 35 respectively. The clamping mechanism 34 can be used as the feeding mechanism in front of the cleaning station 7 and the discharging mechanism behind it, without additional components.

[0060] After the profile is clamped by the two booms, the relative distance between the two booms and the cleaning tank is realized through the length adjustme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com