Gypsum jade-imitating product and preparation method of same

A gypsum and product technology, applied in the field of gypsum imitation jade products and their preparation, can solve the problems of jade in short supply, no jade warm feeling, poor toughness, etc., and achieve the effects of scientific and reasonable raw material formula, warm color and good crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of gypsum imitation jade products, comprising the steps of:

[0025] Step 1. Mold making: First, laser cut the plexiglass plate, then machine tool turning, polishing and laser engraving to make molds, use 3D printers to make various art molds, and then in a vacuum environment, mold the molds Turn it into a silicone rubber mold;

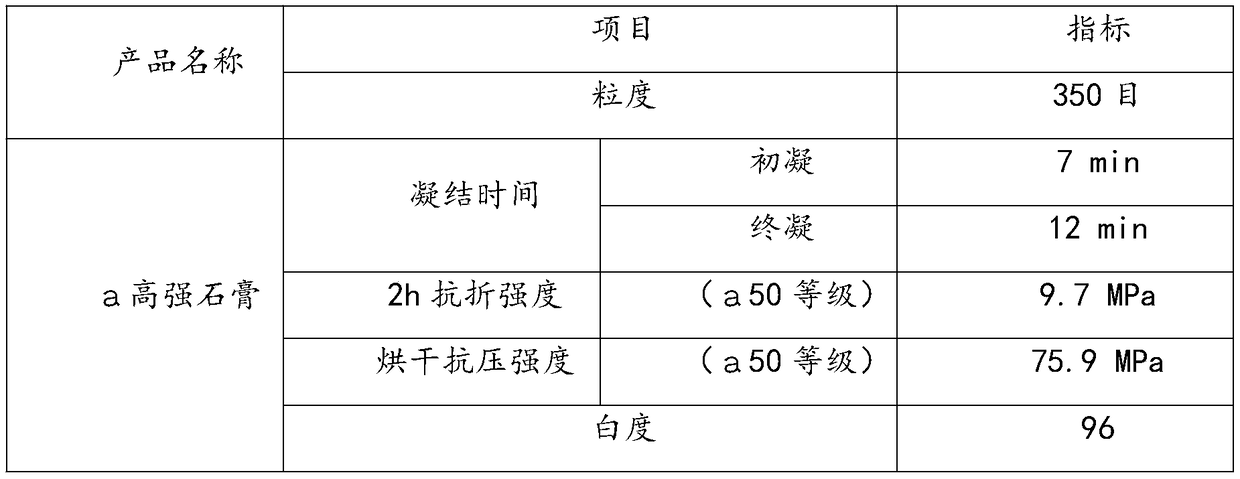

[0026] Step 2, configure casting material: configure 8 parts of α gypsum and 2 parts of gypsum whiskers to form a gypsum mixture, then prepare an aqueous solution with 3.5 parts of deionized water, 0.3 parts of silica sol and 0.013 parts of gypsum defoamer; The gypsum mixture is mixed with the aqueous solution, and stirred evenly in a vacuum environment, the stirring speed is 300-400r / min, the vacuum degree is -0.085~-0.095mPa, and the stirring time is 2-4 minutes, to obtain a casting material;

[0027] Step 3, casting molding: the silicone rubber mold obtained in step 1 is coated with a release agent, and spice tablets (p...

Embodiment 2

[0030] A preparation method of gypsum imitation jade products, comprising the steps of:

[0031] Step 1. Mold making: First, laser cut the plexiglass plate, then machine tool turning, polishing and laser engraving to make molds, use 3D printers to make various art molds, and then in a vacuum environment, mold the molds Turn it into a silicone rubber mold;

[0032] Step 2. Configure casting material: prepare 7 parts of α gypsum and 1 part of gypsum whiskers to form a gypsum mixture, then prepare an aqueous solution with 3 parts of deionized water, 0.2 parts of silica sol and 0.01 part of gypsum defoamer; The gypsum mixture is mixed with the aqueous solution, and stirred evenly in a vacuum environment, the stirring speed is 300-400r / min, the vacuum degree is -0.085~-0.095mPa, and the stirring time is 2-4 minutes, to obtain a casting material;

[0033] Step 3, casting molding: the silicone rubber mold obtained in step 1 is coated with a release agent, and spice tablets (pills), ...

Embodiment 3

[0036] A preparation method of gypsum imitation jade products, comprising the steps of:

[0037]Step 1. Mold making: First, laser cut the plexiglass plate, then machine tool turning, polishing and laser engraving to make molds, use 3D printers to make various art molds, and then in a vacuum environment, mold the molds Turn it into a silicone rubber mold;

[0038] Step 2, configure the casting material: configure 9 parts of α gypsum and 3 parts of gypsum whiskers into a gypsum mixture, then prepare an aqueous solution with 4.5 parts of deionized water, 0.4 parts of silica sol and 0.02 parts of gypsum defoamer; The gypsum mixture is mixed with the aqueous solution, and stirred evenly in a vacuum environment, the stirring speed is 300-400r / min, the vacuum degree is -0.085~-0.095mPa, and the stirring time is 2-4 minutes, to obtain a casting material;

[0039] Step 3, casting molding: the silicone rubber mold obtained in step 1 is coated with a release agent, and spice tablets (pi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com