Electrochemical dechlorination device and method for reinforced concrete

A technology for reinforced concrete and concrete, applied in the field of electrochemical repair, can solve the problems affecting the migration and diffusion effect of chloride ions, the pH value change of electrolyte, contaminate the surface of concrete, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

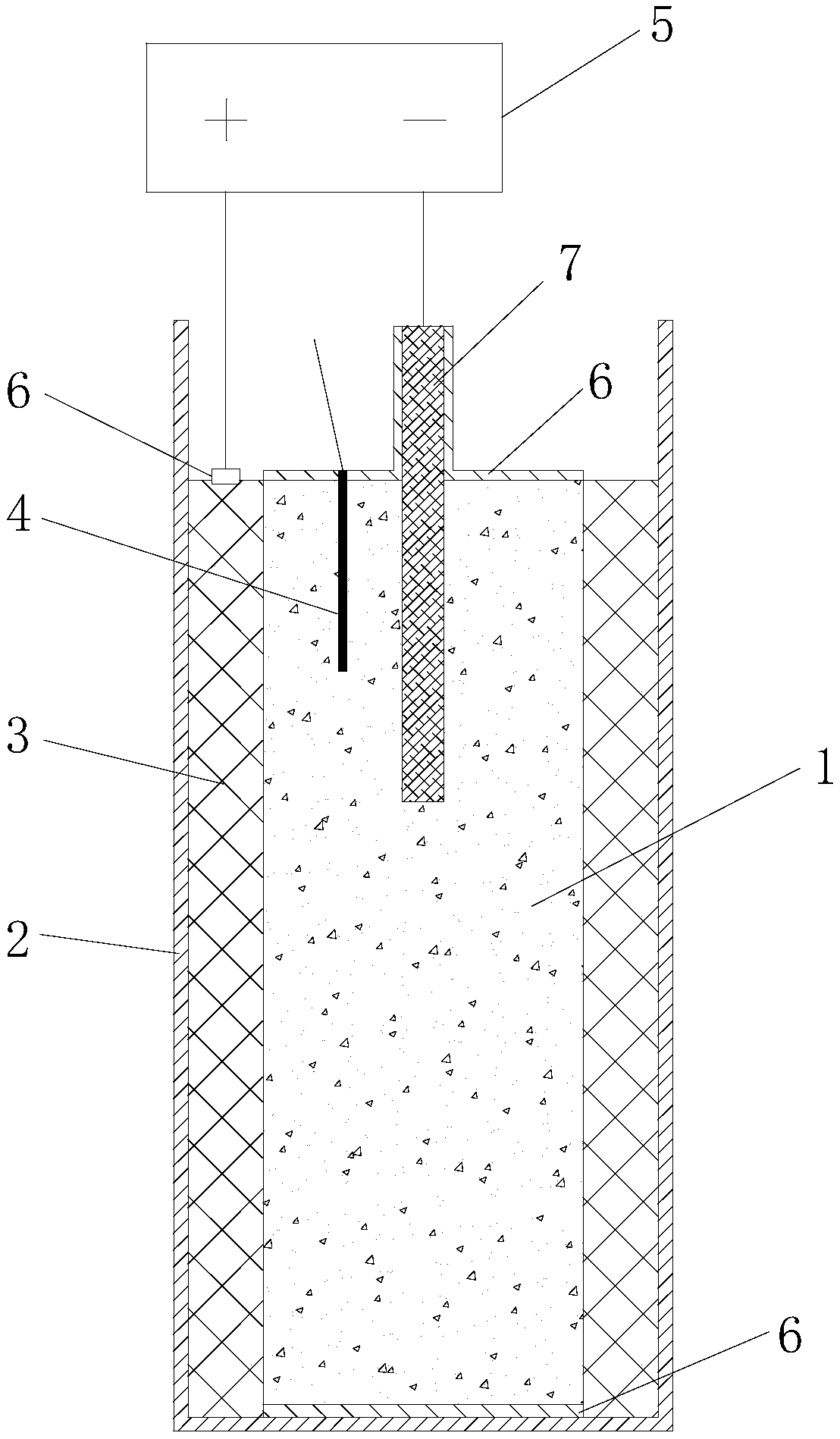

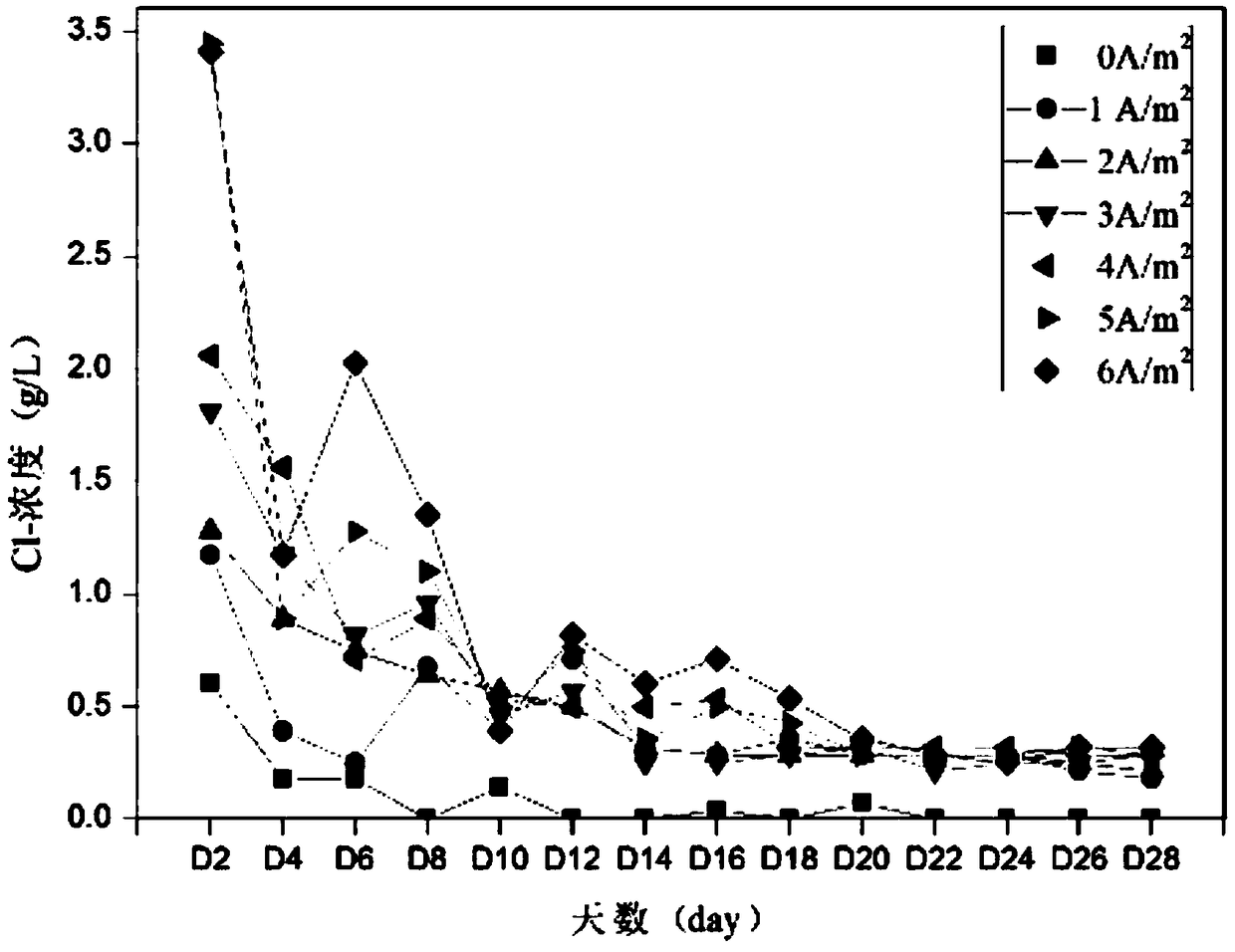

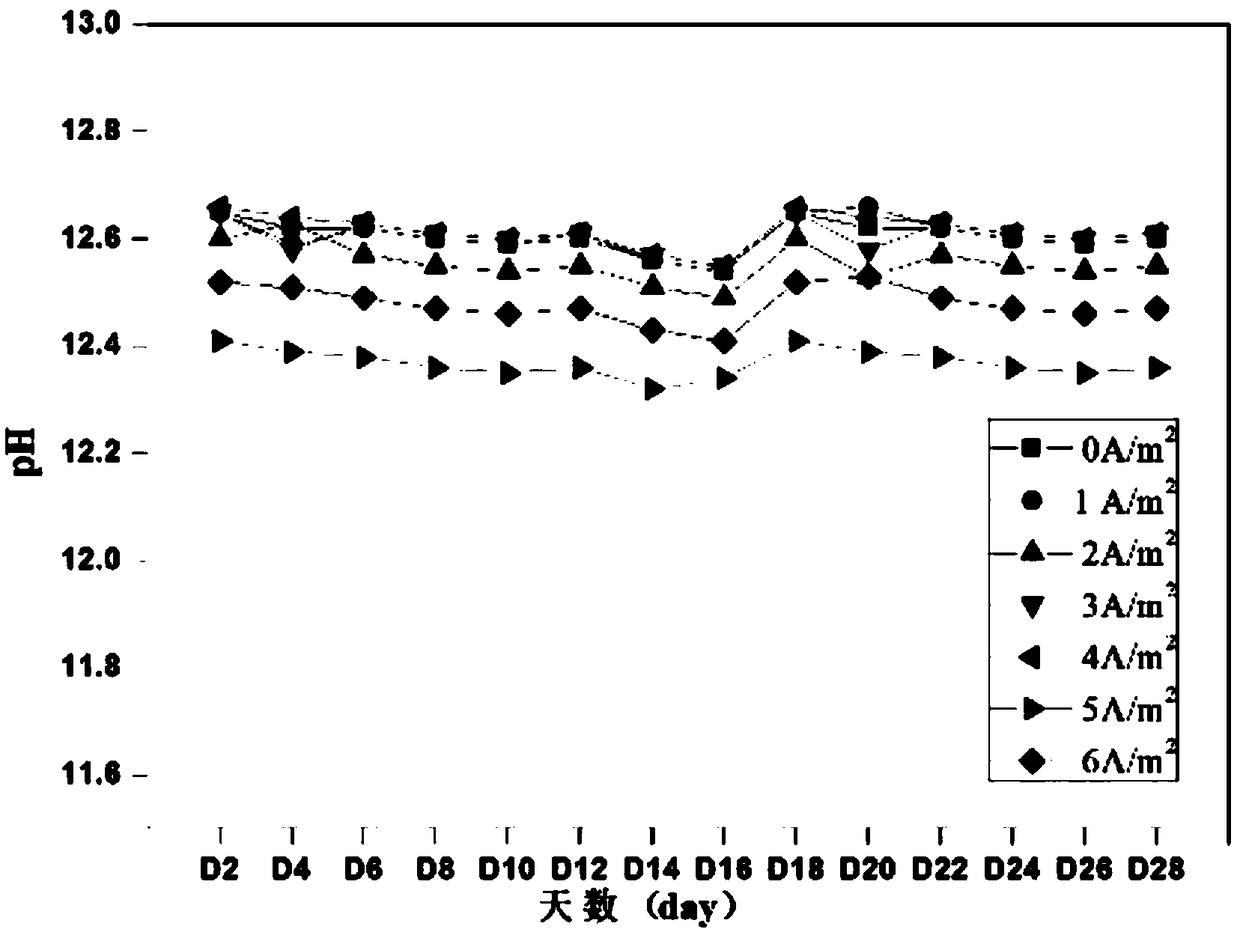

[0028] Concrete 1 is configured with the mix ratio of number B-PC-005, the cement ratio is shown in Table 1, and the specification of concrete 1 is The chlorine salt pollution of concrete 1 is simulated by the method of pre-dosing chlorine salt. The formed concrete 1 contains 3% chlorine (accounting for the mass fraction of cement). The upper end of the composite probe 4 is drawn from the upper end surface of the concrete 1, and the composite probe 4 is placed at a distance of 22 mm from the outer wall of the steel bar 7 and 5 cm from the upper surface of the concrete 1. The lead-out line of the composite probe 4 is connected to the electrochemical workstation. The needle 4 is used to detect the chloride ion concentration and pH value at different positions of the steel bar 7 and the concrete 1 during the electrochemical dechlorination process. Cured for 90 days at (20±2)°C and relative humidity >90%. Before curing, seal the side surfaces of the exposed steel bar 7 and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com