Conductive rolling bearing with nickel graphite conductive coating and preparation method

A conductive coating and rolling bearing technology, which is applied in rolling contact bearings, rotating bearings, bearings, etc., can solve the problem of unavoidable eddy currents in bearing parts, high brittleness of resin-coated insulating coatings, and unavoidable eddy currents in bearing parts etc. to achieve the effects of reducing the probability of breakdown, low cost, and excellent self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

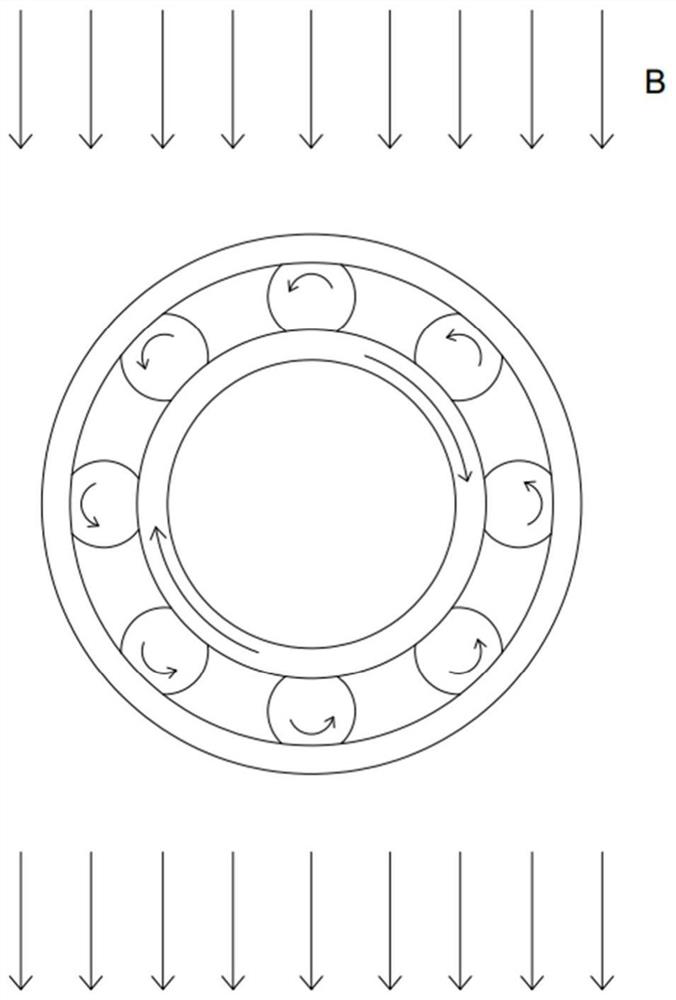

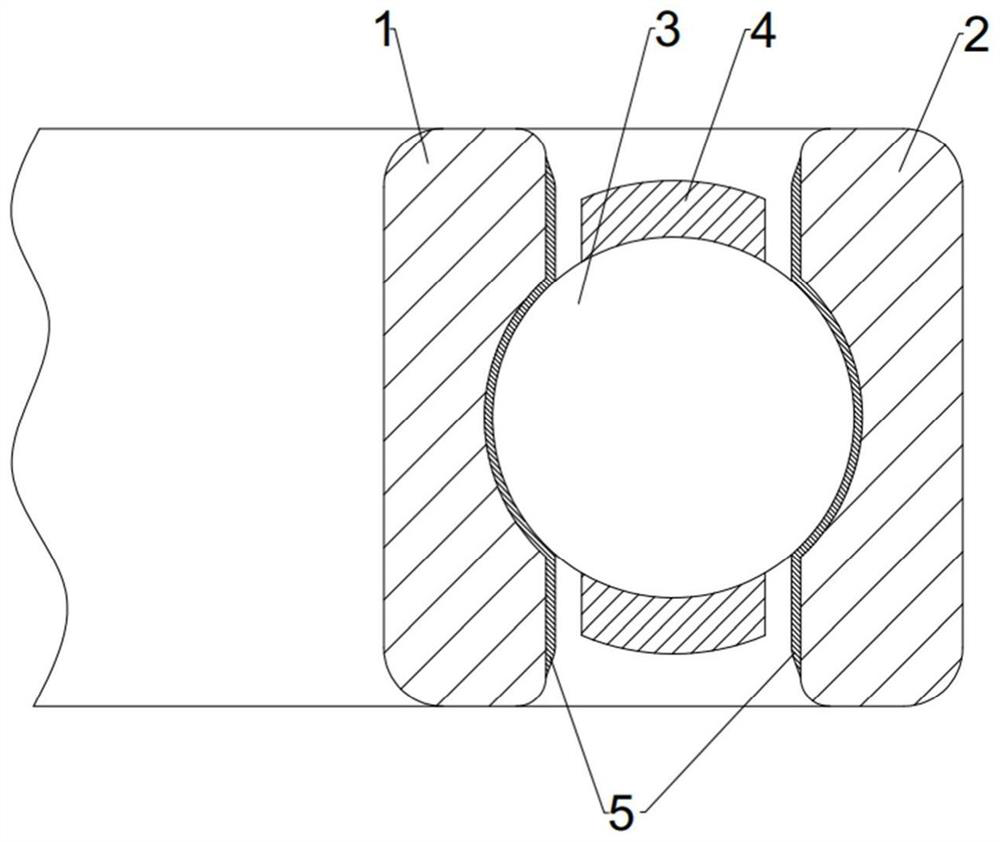

[0041] This embodiment provides a conductive rolling bearing with reliable electrical conductivity, which can effectively lead out the bearing current to prevent electric corrosion, such as figure 2 As shown, the rolling bearing includes a bearing inner ring 1, a bearing outer ring 2, a rolling element 3 and a cage 4, and the rolling element 3 is installed between the bearing inner ring 1 and the bearing outer ring 2 through the cage 4, and the bearing inner ring 1 and the bearing The raceway surfaces of the outer ring 2 are all coated with a layer of nickel graphite conductive coating 5 . The nickel-graphite conductive coating evenly covers the entire raceway surface of the bearing inner ring 1 and the bearing outer ring 2 or the outer surface of the rolling body 3 .

[0042] The greater the thickness of the nickel-graphite conductive coating 5, the higher the porosity of the coating surface, and the electrical conductivity of the coating will decrease thereupon; the greater...

Embodiment 2

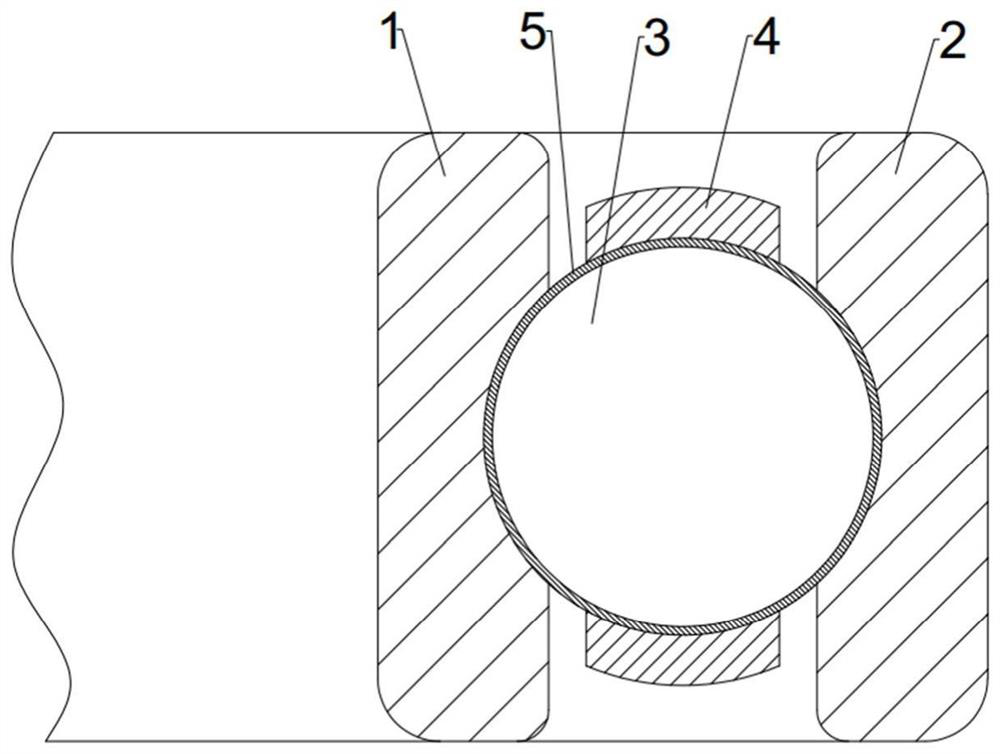

[0047] This embodiment provides a conductive rolling bearing with reliable electrical conductivity, which can effectively lead out the bearing current to prevent electric corrosion, such as image 3 As shown, the rolling bearing includes bearing inner ring 1, bearing outer ring 2, rolling element 3 and cage 4, rolling element 3 is installed between bearing inner ring 1 and bearing outer ring 2 through cage 4, and the outer surface of rolling element 3 is coated Covered with a layer of nickel graphite conductive coating 5. The nickel-graphite conductive coating evenly covers the entire raceway surface of the bearing inner ring 1 and the bearing outer ring 2 or the outer surface of the rolling body 3 .

[0048] The greater the thickness of the nickel-graphite conductive coating 5, the higher the porosity of the coating surface, and the electrical conductivity of the coating will decline thereupon; The binding force on the surface of the body 3 will decrease accordingly, the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com