A kind of high-strength transparent hydrophobic cellulose nano film and preparation method thereof

A cellulose and hydrophobic technology, which is applied in the field of high-strength transparent hydrophobic cellulose nano-membrane and its preparation, can solve the problems of high cost, high production cost, unfriendly environment, etc., achieve improved film-forming performance, low equipment requirements, Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

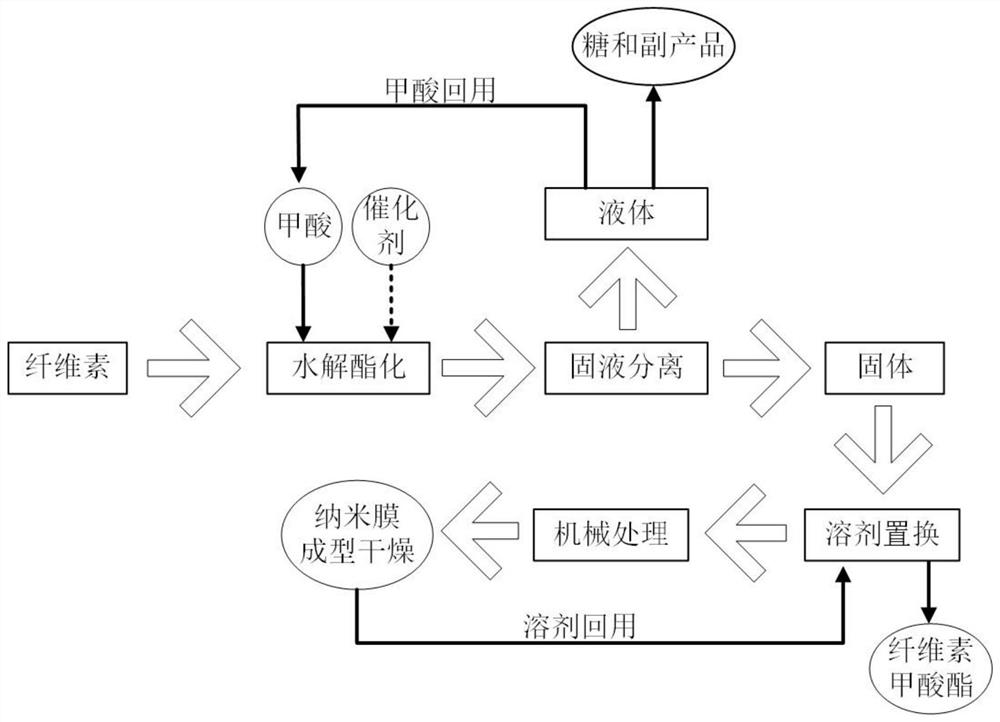

Method used

Image

Examples

Embodiment 1

[0039] The preparation of high-strength transparent cellulose nano-film with commercial bleached coniferous wood paddle board mainly includes the following steps:

[0040] 1) Disperse the bleached coniferous wood paddles with a pulverizer, then take 50 g of the disintegrated raw materials and place them in a reaction kettle, and add 1000 mL of 88 wt % formic acid solution. Then hydrolyze at 100°C for 6 hours, adjust the stirring speed to 600 rpm, cool to room temperature after the reaction, and separate the solid and liquid by suction filtration. The separated solid continues to be filtered and washed with water until neutral cellulose solid is obtained; the separated liquid is distilled under reduced pressure to recover formic acid, and at the same time, the sugar in the liquid can be recovered.

[0041] 2) Replace the washed cellulose solid solvent into DMAC, and adjust the mass concentration of its cellulose DMAC suspension to 0.2 wt%; the DMAC replacement solution and the ...

Embodiment 2

[0044] The method for preparing a high-strength cellulose nano-membrane using commercial bleached wheat straw pulp as a raw material comprises the following steps:

[0045] 1) Disperse the bleached wheat straw pulp board mechanically with a pulverizer, then take 50 g of the above-mentioned raw materials and place them in a reaction kettle, and add 1200 mL of 95 wt % formic acid solution. Then hydrolyze at 85° C. for 5 h, adjust the stirring speed to 200 rpm, cool to room temperature after the reaction, and separate solid and liquid by suction filtration. The separated solid is washed with water until neutral to obtain a cellulose solid; the separated liquid is distilled under reduced pressure to recover formic acid, and simultaneously recover the sugar dissolved in the reaction process.

[0046] 2) Replace the washed cellulose solid solvent into DMF, and adjust its mass concentration to 0.4wt%. Subsequently, the above-mentioned suspension is subjected to high-pressure homogen...

Embodiment 3

[0049] A method for preparing a transparent high-strength cellulose nanofilm from bleached hardwood paddle boards, comprising the following steps:

[0050] 1) Break up the paddles with a pulverizer, then take 50 g of the above-mentioned raw materials and place them in a reaction kettle, and add 1500 mL of 80 wt % formic acid solution. Then hydrolyze at 100°C for 8 hours, adjust the stirring speed to 400 rpm, cool to room temperature after the reaction, and separate the solid and liquid by suction filtration. The separated solid is filtered and washed with deionized water until neutral cellulose solid is obtained; the separated liquid is distilled under reduced pressure to recover formic acid and simultaneously recover sugar products.

[0051] 2) Replace the washed cellulose solid solvent into DMSO, and adjust its mass concentration to 0.3wt%. The above-mentioned suspension is then subjected to ultrasonic crushing treatment, and the processing condition is: 1000W ultrasonic cr...

PUM

| Property | Measurement | Unit |

|---|---|---|

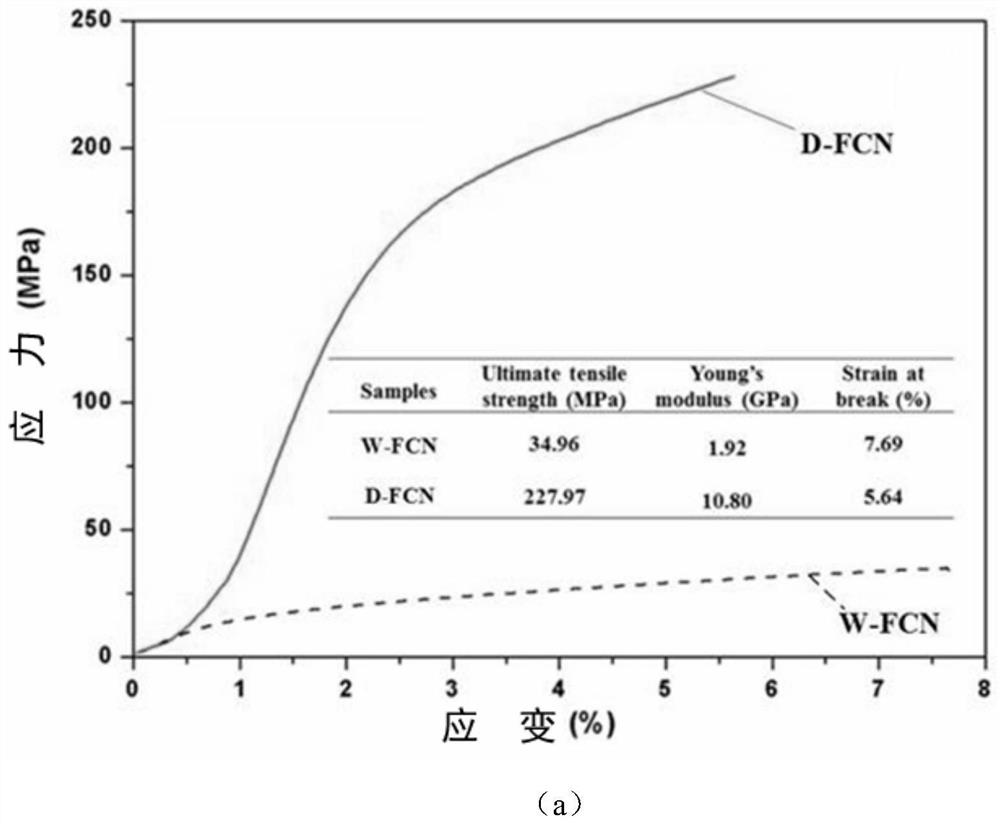

| tensile strength | aaaaa | aaaaa |

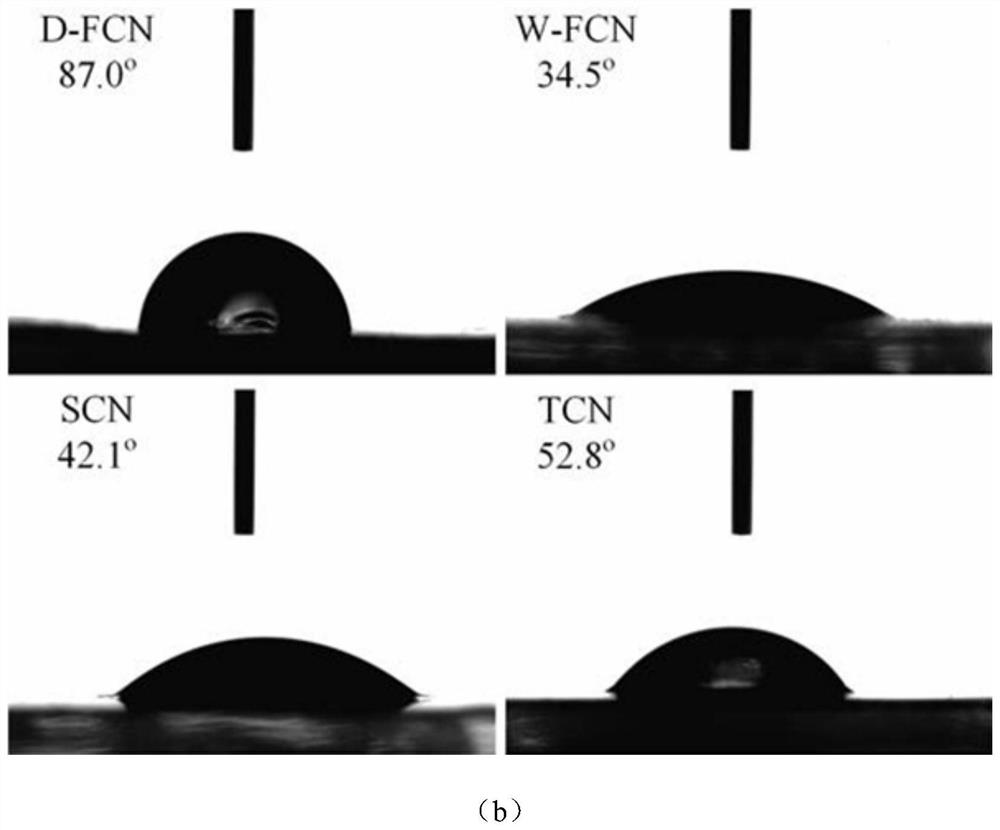

| water contact angle | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com