Plastic-wood composite material with low linear thermal expansion coefficient and preparation method thereof

A technology of plastic-wood composite material and thermal expansion coefficient, which is applied in the field of plastic-wood composite material with low linear thermal expansion coefficient, can solve the problems of affecting appearance and use effect, high thermal expansion coefficient, and achieve the effect of enhancing strength, high strength and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

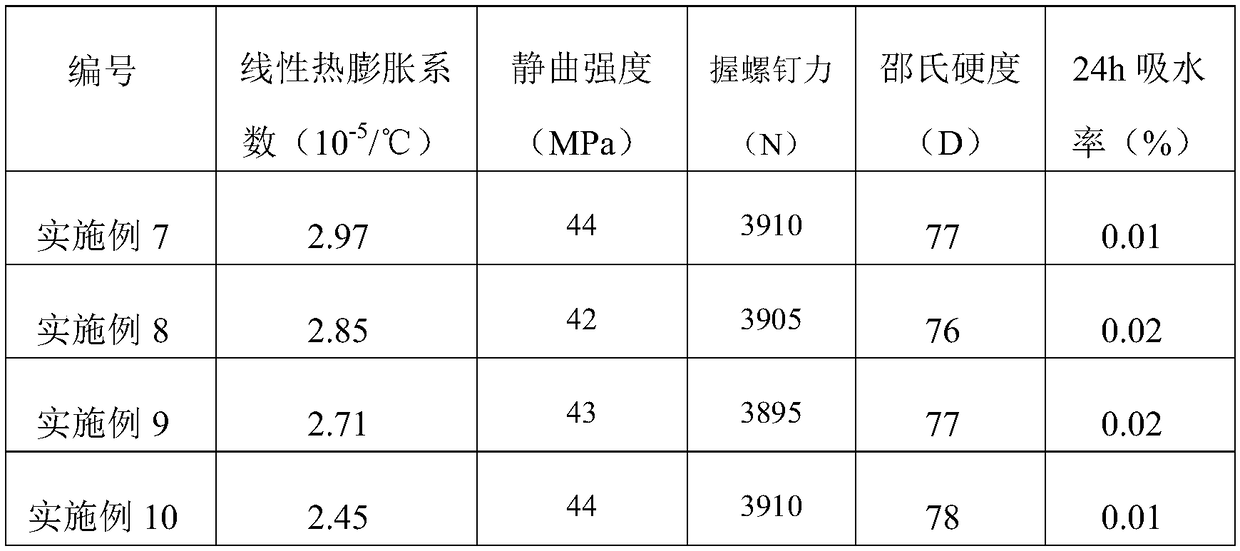

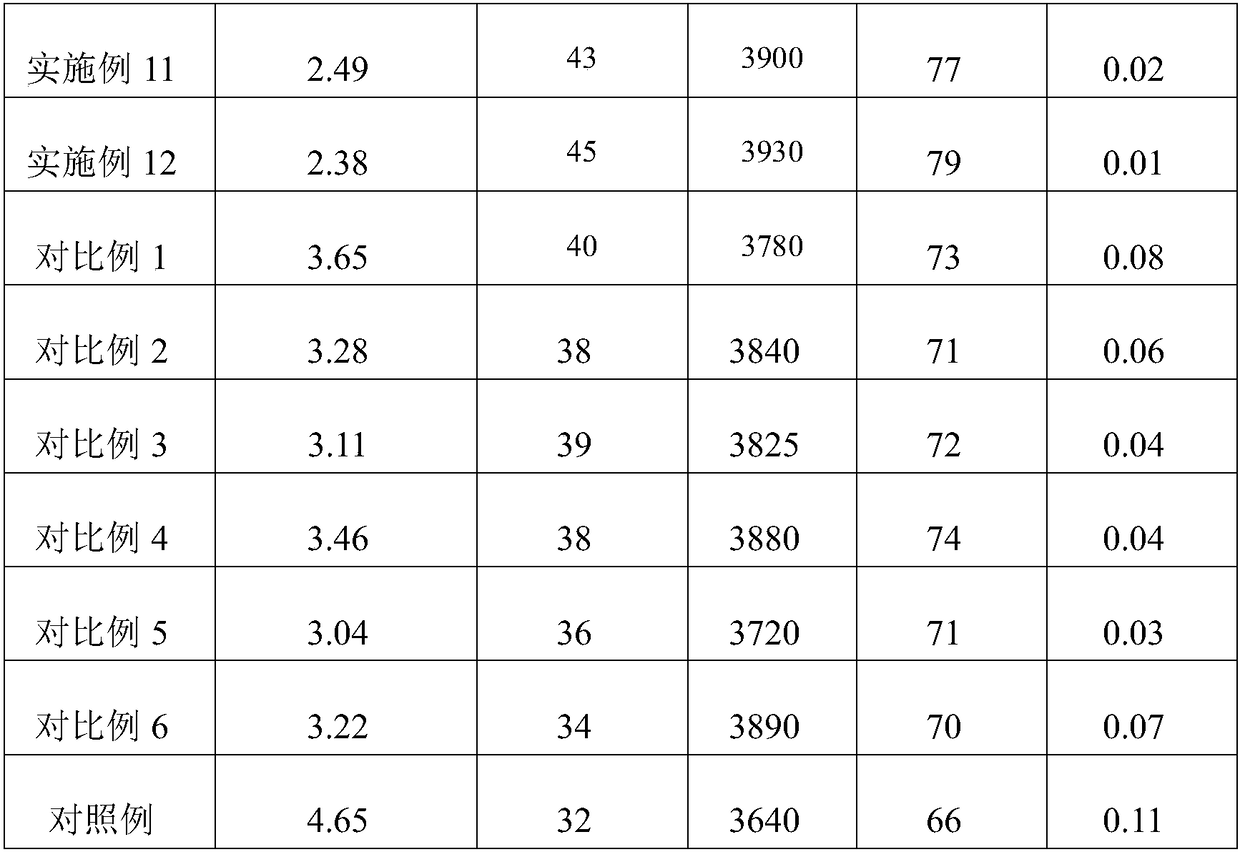

Examples

Embodiment 1

[0031] Embodiment 1 Preparation of modified wood flour

[0032] The modified wood flour described in this example is obtained by modifying wood flour with a phenolic resin adhesive. The specific preparation steps include: according to the mass ratio of 0.05:1, commercially available Dissolve phenolic resin adhesive and wood powder with a particle size of 0.5-1.5mm in water and mix well, and heat up to 50-60°C for a full mixing reaction for 1-3 hours. After the reaction, the solvent water is removed under reduced pressure, and then Put it into an oven and dry it at 70-90°C to get the desired modified wood powder.

Embodiment 2

[0033] Embodiment 2 Preparation of modified wood flour

[0034] The modified wood flour described in this example is obtained by modifying wood flour with a phenolic resin adhesive. The specific preparation steps include: according to the mass ratio of 0.2:1, commercially available Dissolve phenolic resin adhesive and wood powder with a particle size of 0.5-1.5mm in water and mix well, and heat up to 50-60°C for a full mixing reaction for 1-3 hours. After the reaction, the solvent water is removed under reduced pressure, and then Put it into an oven and dry it at 70-90°C to get the desired modified wood powder.

Embodiment 3

[0035] Embodiment 3 Preparation of modified wood flour

[0036] The modified wood flour described in this example is obtained by modifying wood flour with a phenolic resin adhesive. Dissolve phenolic resin adhesive and wood powder with a particle size of 0.5-1.5mm in water and mix well, and heat up to 50-60°C for a full mixing reaction for 1-3 hours. After the reaction, the solvent water is removed under reduced pressure, and then Put it into an oven and dry it at 70-90°C to get the desired modified wood powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com