Thin spraying material for reinforcement and dust sticking of roadway and preparation method

A technology of sticking dust and thin spraying, applied in coating and other directions, can solve problems such as hidden dangers in production safety, reduce support strength, harsh operating environment, etc., and achieve the effect of wide range of use, enhanced support strength, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

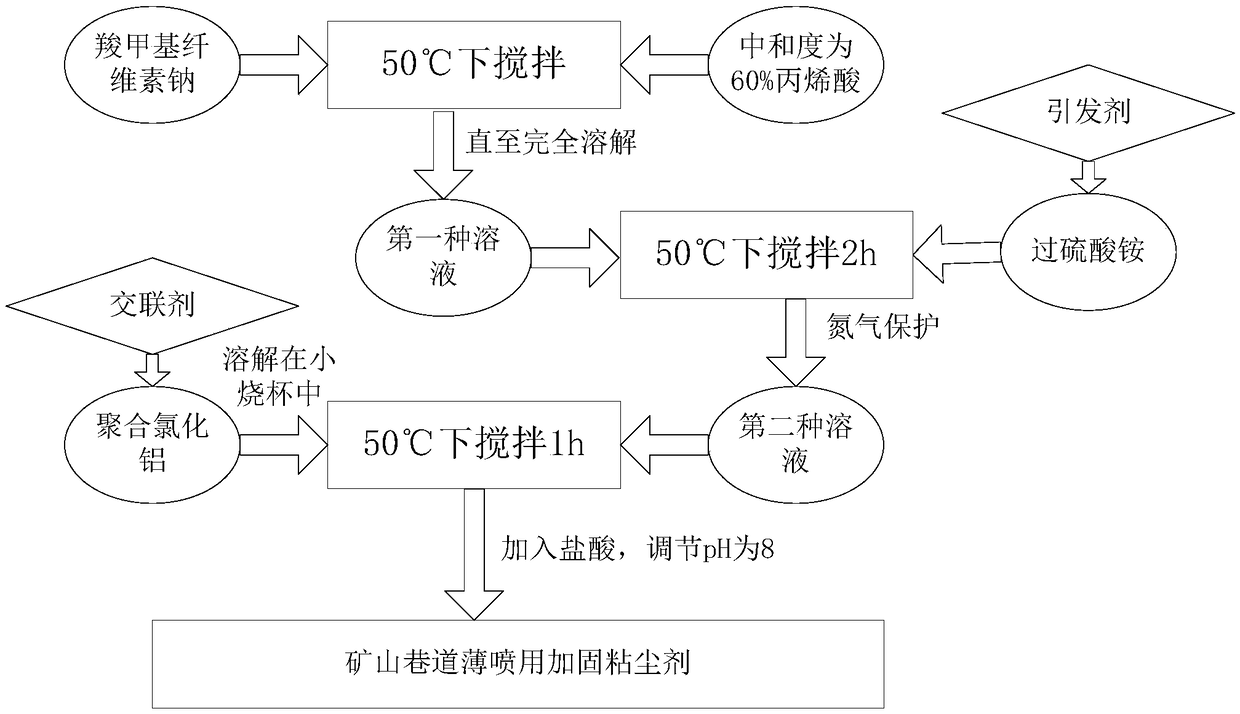

[0027] The present invention also provides a preparation method for roadway reinforcement sticky dust thin spray material, such as figure 1 As shown, it includes the following steps:

[0028] Step 1, add acrylic acid with a neutralization degree of 60% into the reaction vessel, weigh sodium carboxymethylcellulose and slowly add a small amount of sodium carboxymethylcellulose into the reaction vessel under stirring, until the sodium carboxymethylcellulose is completely dissolved to form the first a solution;

[0029]

[0030] Step 2, the above-mentioned first solution is placed in a stirrer and fed with nitrogen for protection, and the reaction temperature is set to the first solution.

[0031] Ammonium persulfate was added in the first solution, and after 2 hours of reaction, the second solution was formed;

[0032]

[0033] Step 3, after weighing polyaluminum chloride, dissolve it in a corresponding container, slowly pour the polyaluminum chloride solution into the ag...

Embodiment 1

[0041] Put the beaker containing 300ml of water in a water bath, adjust the temperature to 50°C, add acrylic acid with a neutralization degree of 60% into the beaker, and weigh 2.5g of sodium carboxymethylcellulose slowly in a stirring state. Add it into a beaker, wait until the sodium carboxymethylcellulose is completely dissolved, place the reactant in a stirrer and pass through nitrogen for protection, set the reaction temperature to 50°C, add 0.05g of ammonium persulfate, react for 2 hours, weigh 0.5g Dissolve the polyaluminum chloride solution in a small beaker, then slowly pour the polyaluminum chloride solution into a stirrer, adjust the pH value to 8, continue stirring for 1 hour, and then add an appropriate amount of hydrochloric acid to obtain a thin spray material for reinforcing sticky dust.

Embodiment 2

[0043] Put the beaker containing 300ml of water in a water bath, adjust the temperature to 50°C, add acrylic acid with a neutralization degree of 60% into the beaker, and weigh 2.5g of sodium carboxymethylcellulose slowly in a stirring state. Add it into a beaker, wait until the sodium carboxymethylcellulose is completely dissolved, place the reactant in a stirrer and feed it with nitrogen for protection, set the reaction temperature to 50°C, add 0.04g ammonium persulfate, react for 2 hours, weigh 0.4g Dissolve the polyaluminum chloride solution in a small beaker, then slowly pour the polyaluminum chloride solution into a stirrer, adjust the pH value to 8, continue stirring for 1 hour, and then add an appropriate amount of hydrochloric acid to obtain a thin spray material for reinforcing sticky dust.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com