Heat treatment technology of 20CrMnMoA steel bevel gear shaft

A gear shaft and steel cone technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve problems such as low impact toughness, and achieve the effect of improving hardness, high yield strength, and fine grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

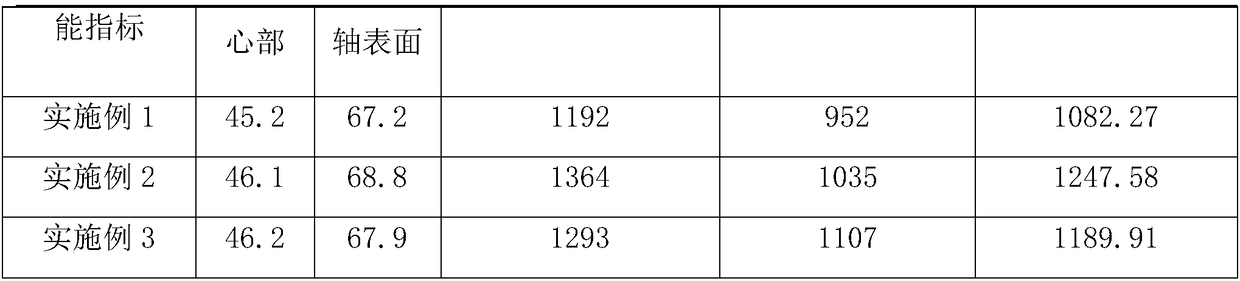

Embodiment 1

[0024] A heat treatment process for a 20CrMnMoA steel bevel gear shaft, the chemical element composition and mass percentage of the 20CrMnMoA steel bevel gear shaft are: C: 0.17%, Si: 0.17%, Mn: 0.8%, Cr: 1.0%, Ti: 0.04 %, Mo: 0.20%, Ni<0.03%, Cu<0.03%, P<0.035%, S<0.035%, the balance is iron, and the heat treatment process includes the following steps:

[0025] S1: Carburizing: Use the method of heating to high temperature. After the gas carburizing furnace is heated to 920-930 ° C, put the bevel gear shaft vertically into the furnace, exhaust, keep warm for 2.5 hours, and drop 160-180 drops of kerosene during the heat preservation / min, the temperature of the infiltrated layer will drop to 830±10℃ after meeting the requirements;

[0026] S2: heat preservation: heat preservation and soaking for 2 hours;

[0027] S3: two-stage quenching: immerse the bevel gear shaft vertically in calcium chloride solution at a temperature between 820-850 °C, rapidly cool the bevel gear shaft ...

Embodiment 2

[0033] A heat treatment process for a 20CrMnMoA steel bevel gear shaft, the chemical element composition and mass percentage of the 20CrMnMoA steel bevel gear shaft are: C: 0.23%, Si: 0.37%, Mn: 1.3%, Cr: 1.3%, Ti: 0.12 %, Mo: 0.30%, Ni<0.03%, Cu<0.03%, P<0.035%, S<0.035%, the balance is iron, and the heat treatment process includes the following steps:

[0034] S1: Carburizing: Use the method of heating to high temperature. After the gas carburizing furnace is heated to 920-930 ° C, put the bevel gear shaft vertically into the furnace, exhaust, keep warm for 2.5 hours, and drop 160-180 drops of kerosene during the heat preservation / min, the temperature of the infiltrated layer will drop to 830±10℃ after meeting the requirements;

[0035] S2: heat preservation: heat preservation and soaking for 2 hours;

[0036] S3: two-stage quenching: immerse the bevel gear shaft vertically in calcium chloride solution at a temperature between 820-850 °C, rapidly cool the bevel gear shaft ...

Embodiment 3

[0042]A heat treatment process for a 20CrMnMoA steel bevel gear shaft, the chemical element composition and mass percentage of the 20CrMnMoA steel bevel gear shaft are: C: 0.21%, Si: 0.26%, Mn: 0.11%, Cr: 1.2%, Ti: 0.08 %, Mo: 0.25%, Ni<0.03%, Cu<0.03%, P<0.035%, S<0.035%, the balance is iron, and the heat treatment process includes the following steps:

[0043] S1: Carburizing: Use the method of heating to high temperature. After the gas carburizing furnace is heated to 920-930 ° C, put the bevel gear shaft vertically into the furnace, exhaust, keep warm for 2.5 hours, and drop 160-180 drops of kerosene during the heat preservation / min, the temperature of the infiltrated layer will drop to 830±10℃ after meeting the requirements;

[0044] S2: heat preservation: heat preservation and soaking for 2 hours;

[0045] S3: two-stage quenching: immerse the bevel gear shaft vertically in the calcium chloride solution at a temperature between 820-850 °C, rapidly cool the bevel gear sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com