High-sensitivity surface plasma resonant cavity sensor corrected through graphene

A high-sensitivity, plasma-harmonic technology, applied in the field of optical communication technology and sensing, can solve problems such as difficult mass production, complex sensor preparation methods, and difficulty in filling sensing media.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

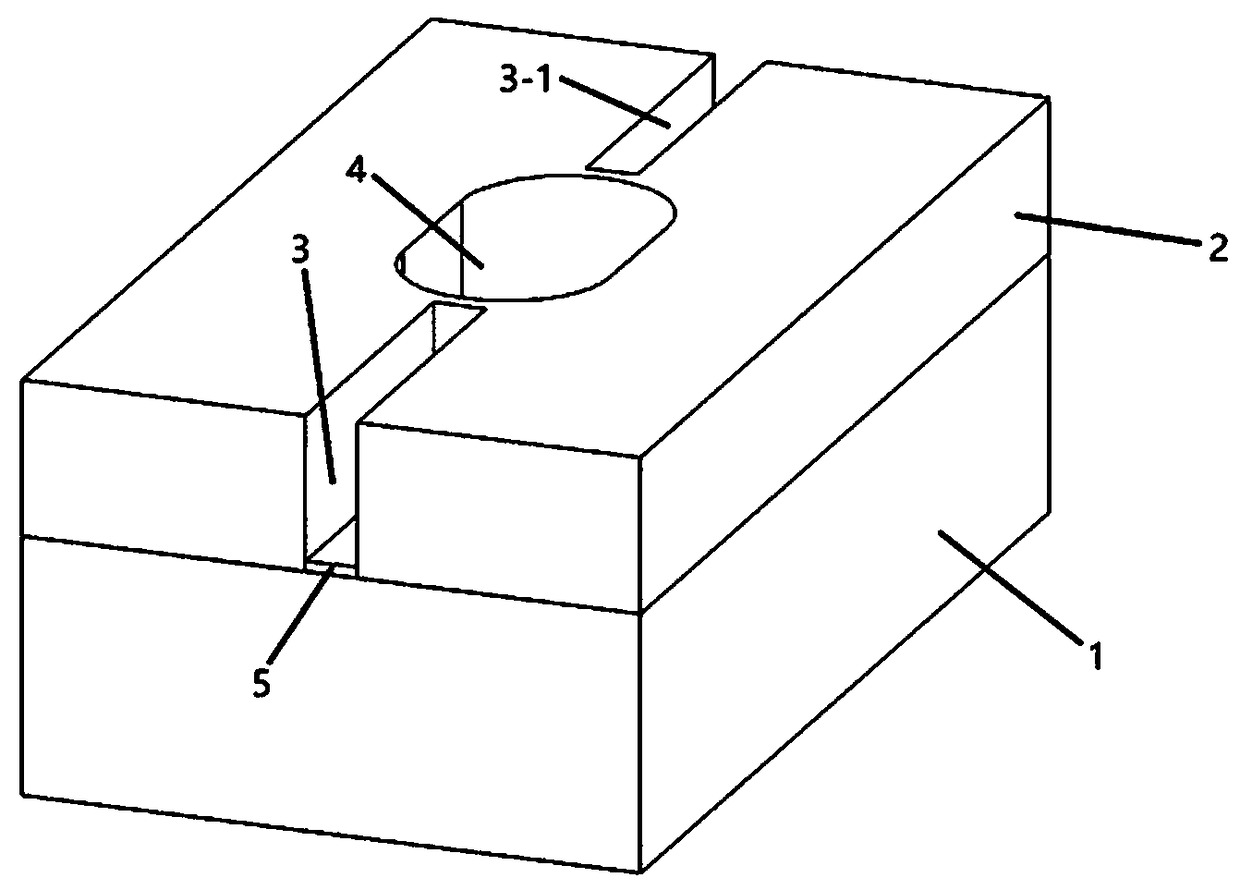

[0023] refer to figure 1 , a high-sensitivity surface plasmon resonant cavity sensor modified by graphene, including a base layer 1 and a metal layer 2 stacked from bottom to top, and the metal layer 2 is provided with a resonant cavity 4 penetrating the upper and lower surfaces of the metal layer 2 , the perimeter of the resonant cavity 4 is symmetrically provided with a concave first straight waveguide 3 and a concave second straight waveguide 3-1, and the bottoms of the first straight waveguide 3 and the second straight waveguide 3-1 are all provided with single-layer graphene 5 It is tightly overlapped with the base layer 1.

[0024] The temperature sensing medium in the resonant cavity 4 is a liquid material with a high thermo-optic coefficient. In this example, it is sunflower oil. The length and width of the resonant cavity 4 can be adjusted. , wide size to carry out corresponding quantitative adjustments, so as to achieve the performance of optical filtering.

[0025...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com