Peeling device and peeling method for cylindrical battery

A cylindrical battery and battery technology, which is applied in the use/repair of primary batteries, battery recycling, and repair/maintenance of secondary batteries, etc. Fast peeling speed, large-scale automated production, and improved recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

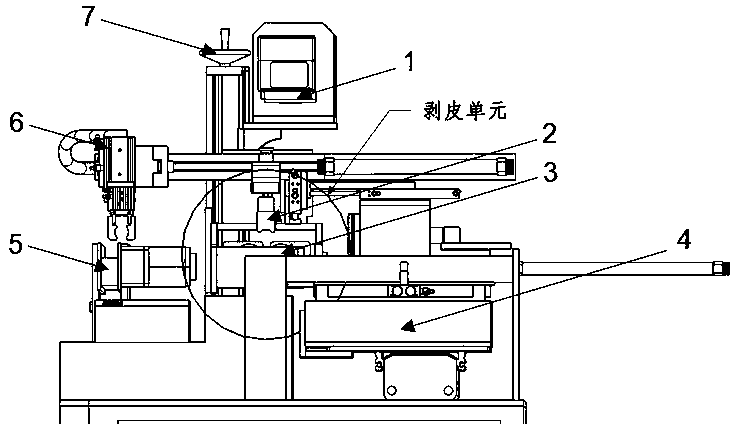

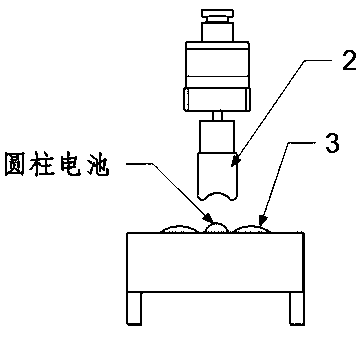

[0018] as attached figure 1 As shown, a cylindrical battery peeling device, its structure includes a laser head 1, a lower pressure transfer machine 2, a roller peeling device 3, a battery storage bin 4, a battery conveyor belt 5, a cutting transfer machine 6, a laser head Lifting device 7; wherein the laser head 1 is connected and fixed with the laser head lifting device 7, the cutting transfer machine 6 and the pressing transfer machine 2 are arranged under the laser head 1, and the battery conveyor is arranged under the left end of the cutting transfer machine 6 Belt 5; a roller peeling device 3 is provided below the lower pressure transfer machine 2, and the outlet end of the roller peeling device 3 is connected to the battery storage bin 4; the whole device is arranged on a horizontal frame.

[0019] The laser head lifting device 7 is installed on a longitudinal chute, and can vertically move up and down along the longitudinal chute to adjust the height position of the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com