Method for improving dyed rate of wicker products

A technology of weaving products and willow weaving, applied in the field of improving the dye penetration rate of willow weaving products, can solve the problems of affecting quality and color fading, and achieve the effects of avoiding color fading, enhancing air permeability and improving permeability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

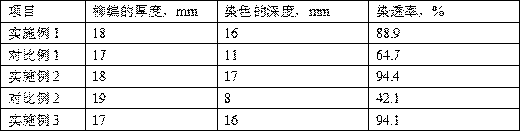

Examples

Embodiment 1

[0018] A method for improving the dyeing rate of willow products, comprising the following steps:

[0019] (1) Dry the woven willow products to a moisture content of 13%, and then oxidize the surface;

[0020] (2) Then put the wickerwork into the dyeing solution, slowly raise the temperature of the dyeing solution to 68°C, and heat it for 8 hours. The dyeing solution is made of the following components by weight: 138 parts of polyethanolamine, diphenylamine sulfonate 3 parts of sodium bicarbonate, 4 parts of modified multi-walled carbon nanotubes, 6 parts of dyes, and 900 parts of water, wherein the modified multi-walled carbon nanotubes are made by the following method: after the bimetallic coupling agent is heated to a molten state, then Add multi-walled carbon nanotubes 0.8 times its weight therein, mix and stir evenly, and cool to room temperature to obtain modified multi-walled carbon nanotubes;

[0021] (3) Add dyeing solution with 0.5% volume of dyeing solution into th...

Embodiment 2

[0028] A method for improving the dyeing rate of willow products, comprising the following steps:

[0029] (1) Dry the woven wicker products to a moisture content of 15%, and then oxidize the surface;

[0030] (2) Then put the wickerwork into the dyeing solution, slowly raise the temperature of the dyeing solution to 72°C, and heat it for 9 hours, wherein the dyeing solution is made of the following components by weight: 142 parts of polyethanolamine, diphenylamine sulfonate 5 parts of sodium bicarbonate, 6 parts of modified multi-walled carbon nanotubes, 8 parts of dyes, and 950 parts of water, wherein the modified multi-walled carbon nanotubes are made by the following method: after the bimetallic coupling agent is heated to a molten state, then Add multi-walled carbon nanotubes of 0.9 times its weight to it, mix and stir evenly, and cool to room temperature to obtain modified multi-walled carbon nanotubes;

[0031] (3) Add dyeing solution with a volume of 0.7% of the dyein...

Embodiment 3

[0038] A method for improving the dyeing rate of willow products, comprising the following steps:

[0039] (1) Dry the woven willow products to a moisture content of 17%, and then oxidize the surface;

[0040] (2) Then put the willow fabric into the dyeing solution, slowly raise the temperature of the dyeing solution to 77°C, and heat it for 10 hours. The dyeing solution is made of the following components by weight: 145 parts of polyethanolamine, diphenylamine sulfonate 8 parts of sodium bicarbonate, 8 parts of modified multi-walled carbon nanotubes, 9 parts of dyes, and 1000 parts of water, wherein the modified multi-walled carbon nanotubes are made by the following method: after the bimetallic coupling agent is heated to a molten state, then Add multi-walled carbon nanotubes 1.0 times its weight therein, mix and stir evenly, and cool to room temperature to obtain modified multi-walled carbon nanotubes;

[0041] (3) Add dyeing solution with a volume of 0.8% of the dyeing so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com