Preparation method of anion printing and color fixation fabric

A technology of negative ions and negative ion powder, which is applied in the field of textile processing, can solve the problems of low negative ion release, reduced effect, poor durability, etc., and achieve the effects of high release, improved adhesion, and guaranteed color fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

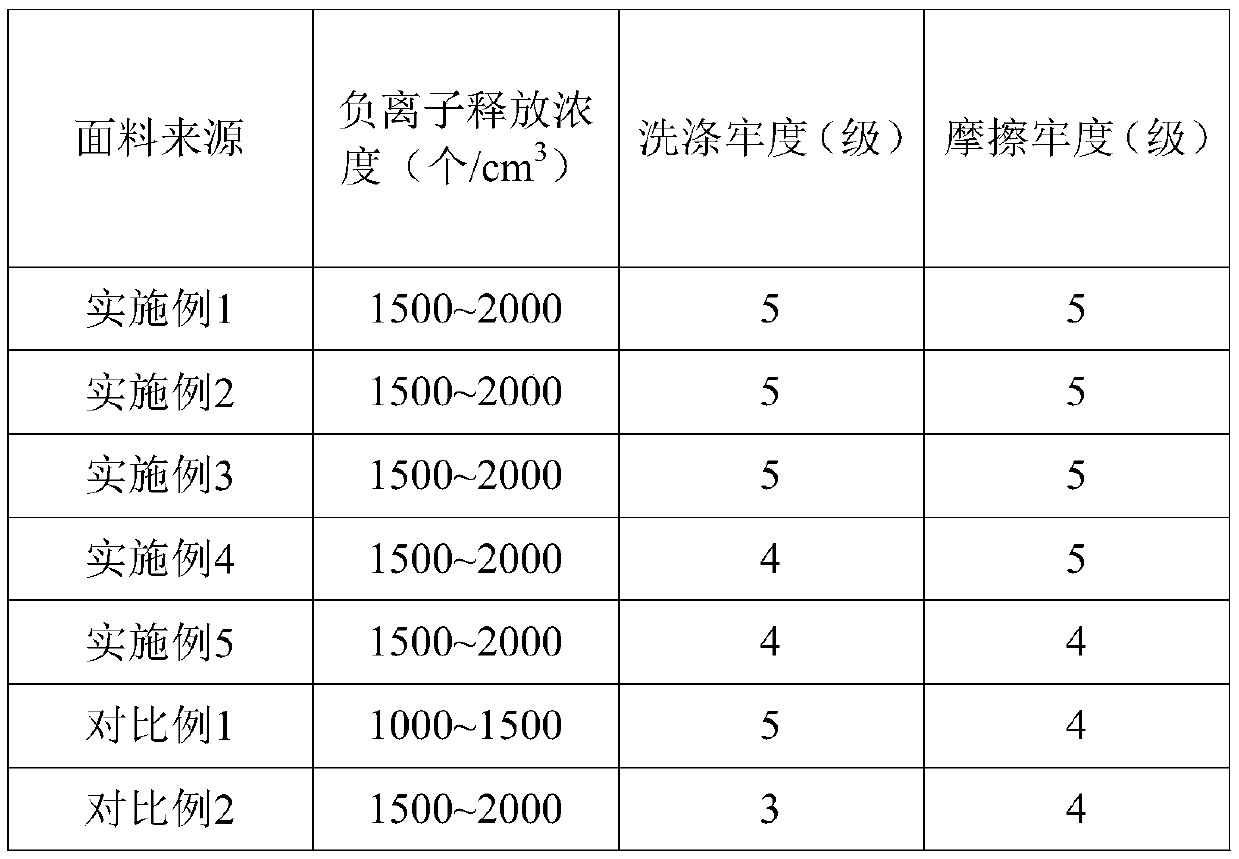

Examples

Embodiment 1

[0027] The preparation method of the negative ion printing color-fixing fabric that present embodiment provides, comprises the steps:

[0028] (1) According to the weight ratio of tourmaline stone powder and gelatin being 0.3:1, at 40°C, add tourmaline stone powder into an aqueous solution of gelatin (mass concentration is 20%), and mix and stir for 10 minutes to obtain anion solution ;

[0029] (2) Prepare N,N-dimethyl-γ-aminopropyl-γ-aminopropyl polydimethylsiloxane and allyl polyoxane in a weight ratio of 11:1:5:10 Epoxy ether, isopropanol, ethyl chloroacetate, N,N-dimethyl-γ-aminopropyl-γ-aminopropyl polydimethylsiloxane, allyl polyoxyalkyl After mixing epoxy ether and isopropanol, react at 75°C for 3.5h, add ethyl chloroacetate under stirring, heat up to 80°C, keep warm for 3.5h, then remove solvent and unreacted After ethyl chloroacetate, the quaternized polyether-modified amino silicone oil was obtained, and the resulting quaternized polyether-modified amino silicone ...

Embodiment 2

[0035] The preparation method of the negative ion printing color-fixing fabric that present embodiment provides, comprises the steps:

[0036] (1) According to the weight ratio of tourmaline stone powder and gelatin being 0.4:1, at 40°C, add tourmaline stone powder into the aqueous solution of gelatin (mass concentration is 20%), mix and stir for 12min to obtain anion solution ;

[0037] (2) Prepare N,N-dimethyl-γ-aminopropyl-γ-aminopropyl polydimethylsiloxane and allyl polyoxane in a weight ratio of 12:1:5:10 Epoxy ether, isopropanol, ethyl chloroacetate, N,N-dimethyl-γ-aminopropyl-γ-aminopropyl polydimethylsiloxane, allyl polyoxyalkyl After mixing epoxy ether and isopropanol, react at 75°C for 3h, add ethyl chloroacetate under stirring, raise the temperature to 80°C, keep warm for 3.5h, then remove the solvent and unreacted chlorine by distillation under reduced pressure After ethyl acetate, the quaternized polyether-modified amino silicone oil is obtained, and the resulti...

Embodiment 3

[0043] The preparation method of the negative ion printing color-fixing fabric that present embodiment provides, comprises the steps:

[0044] (1) According to the weight ratio of tourmaline stone powder and gelatin being 0.3:1, at 40°C, add calcium carbide gas powder into the aqueous solution of gelatin, and mix and stir for 12 minutes to obtain an anion solution;

[0045] (2) Prepare N,N-dimethyl-γ-aminopropyl-γ-aminopropyl polydimethylsiloxane and allyl polyoxane in a weight ratio of 12:1:5:10 Epoxy ether, isopropanol, ethyl chloroacetate, N,N-dimethyl-γ-aminopropyl-γ-aminopropyl polydimethylsiloxane, allyl polyoxyalkyl After mixing epoxy ether and isopropanol, react at 75°C for 4 hours, add ethyl chloroacetate under stirring, raise the temperature to 80°C, keep warm for 3 hours, and remove the solvent and unreacted chloroacetic acid by distillation under reduced pressure After ethyl ester, the quaternized polyether-modified amino silicone oil is obtained, and the obtained q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com