Mat rush low-temperature dyeing method

A low-temperature dyeing and rush technology, applied in the field of rush low-temperature dyeing, can solve problems such as affecting the mechanical properties of rush, achieve the effect of improving the dyeing rate and rubbing fastness, and having a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

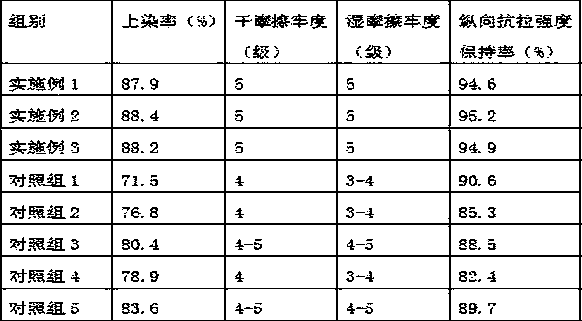

Examples

Embodiment 1

[0017] A low-temperature dyeing method for rush, comprising the following contents:

[0018] (1) After cleaning the collected rush grass, soak it in the pretreatment solution at a temperature of 40°C for 3.5 hours, drain the water after soaking, and conduct plasma treatment on it with a plasma device for 4 minutes, then dry it to Keep the moisture content below 10% for later use;

[0019] The pretreatment liquid includes the following raw materials in parts by weight: 1.2 parts of polyoxyethylene sorbitan monopalmitate, 3.2 parts of sodium fatty alcohol polyoxyethylene ether carboxylate, 3.8 parts of polyvinylpyrrolidone, triethanolamine stearate 7 parts of quaternary ammonium salt, 62 parts of alkaline pectinase solution whose mass concentration is 2.35%;

[0020] (2) Dye the above-treated rush and the composite dye solution at a volume bath ratio of 1:40, the dyeing temperature is 46°C, and the heat preservation treatment is 50 minutes;

[0021] The composite dye solution ...

Embodiment 2

[0029] A low-temperature dyeing method for rush, comprising the following contents:

[0030] (1) After cleaning the collected rush grass, soak it in the pretreatment solution at a temperature of 38°C for 4 hours, drain the water after soaking, and perform plasma treatment on it with a plasma device. After 3 minutes of treatment, dry it until Keep the moisture content below 10% for later use;

[0031] The pretreatment liquid includes the following raw materials in parts by weight: 1.6 parts of polyoxyethylene sorbitan monopalmitate, 2.2 parts of sodium fatty alcohol polyoxyethylene ether carboxylate, 5.3 parts of polyvinylpyrrolidone, triethanolamine stearate 6 parts of quaternary ammonium salt, 65 parts of alkaline pectinase solution whose mass concentration is 2.2%;

[0032] (2) Dye the above-treated rush and the composite dye solution at a volume bath ratio of 1:40, the dyeing temperature is 48°C, and the heat preservation treatment is 60 minutes;

[0033] The composite dy...

Embodiment 3

[0041] A low-temperature dyeing method for rush, comprising the following contents:

[0042] (1) After washing the collected rush grass, soak it in the pretreatment solution at a temperature of 42°C for 3 hours, drain the water after soaking, and conduct plasma treatment on it with a plasma device. After 5 minutes of treatment, dry it until Keep the moisture content below 10% for later use;

[0043] The pretreatment liquid includes the following raw materials in parts by weight: 0.8 parts of polyoxyethylene sorbitan monopalmitate, 4.2 parts of sodium fatty alcohol polyoxyethylene ether carboxylate, 2.4 parts of polyvinylpyrrolidone, triethanolamine stearate 8 parts of quaternary ammonium salt, 60 parts of alkaline pectinase solution whose mass concentration is 2.5%;

[0044] (2) Dye the above-treated rush and the composite dye solution at a volume bath ratio of 1:40, the dyeing temperature is 44°C, and the heat preservation treatment is 40 minutes;

[0045] The composite dye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com