Cotton and polyester cotton blended fabric pre-treatment method

A polyester-cotton blending and fabric technology, which is applied in the treatment of textile materials, the biochemical treatment of enzymes/microorganisms, and the treatment of liquid/gas/steam textiles. Large emissions and other problems, to achieve the effect of simple and easy processing, low weight loss rate, and COD reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

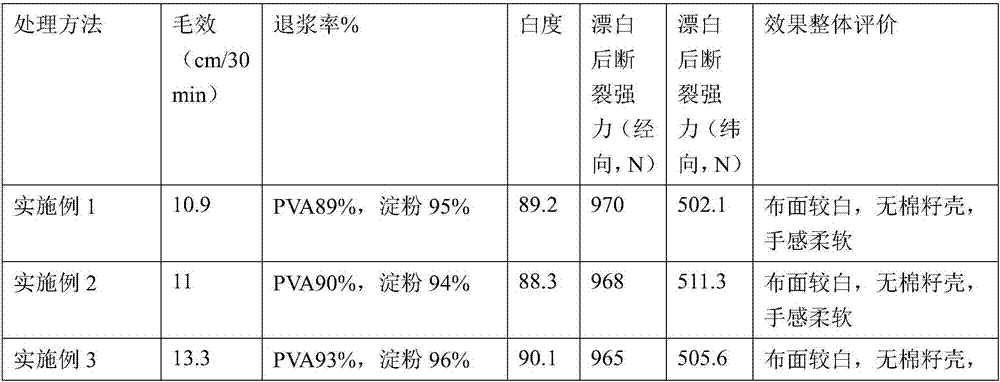

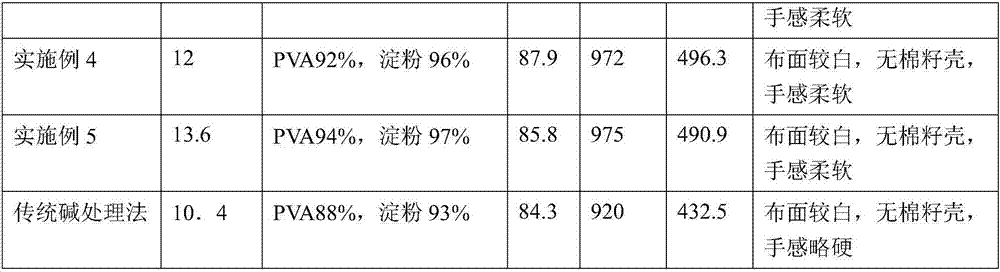

Examples

Embodiment 1

[0024] The pretreatment method of cotton and polyester-cotton blended fabric, its step is:

[0025] Rough cloth → compound biological enzyme pretreatment → stacking at 20-25°C → washing at 60±5°C → drying → padding to remove cotton enzymes → steaming at 100°C for at least 1 hour → washing at 60°C ± 5°C → drying;

[0026] Described composite biological enzyme pretreatment, this process comprises the following steps:

[0027] a) Add water to the mixer, and then add 25 parts of α-amylase, 28 parts of pectinase, 16 parts of xylanase, 14 parts of laccase, 15 parts of cellulase, β- Add 4 parts of dextranase, 11 parts of ligninase, and 6 parts of lipase into the mixer, mix evenly, and prepare a slurry of 120g / L, and then grind it to the particle size with a grinder at 20-25°C 0.3 ~ 0.4 μm, that is, get the complex biological enzyme;

[0028] b) Contains 13g / L compound biological enzyme prepared in step a), 7g / L osmotic emulsification detergent, 10g / L ethylenediaminetetraacetic acid...

Embodiment 2

[0035] The pretreatment method of cotton and polyester-cotton blended fabric, its step is:

[0036] Rough cloth → compound biological enzyme pretreatment → stacking at 20-25°C → washing at 60±5°C → drying → padding to remove cotton enzymes → steaming at 100°C for at least 1 hour → washing at 60°C ± 5°C → drying;

[0037] Described composite biological enzyme pretreatment, this process comprises the following steps:

[0038]a) Add water to the mixer, and then add 28 parts of α-amylase, 30 parts of pectinase, 19 parts of xylanase, 16 parts of laccase, 14 parts of cellulase, β- Add 3 parts of dextranase, 11 parts of ligninase, and 6 parts of lipase into the mixer, mix evenly, and prepare a slurry of 140g / L, and then grind it to the particle size with a grinder at 20-25°C 0.3 ~ 0.4 μm, that is, get the complex biological enzyme;

[0039] b) Contains 15g / L compound biological enzyme prepared in step a), 6g / L osmotic emulsification detergent, 9g / L ethylenediaminetetraacetic acid (...

Embodiment 3

[0046] A kind of pretreatment method of cotton and polyester-cotton blended fabric, its steps are:

[0047] Rough cloth → compound biological enzyme pretreatment → stacking at 20-25°C → washing at 60±5°C → drying → padding to remove cotton enzymes → steaming at 100°C for at least 1 hour → washing at 60°C ± 5°C → drying;

[0048] Described composite biological enzyme pretreatment, this process comprises the following steps:

[0049] a) Add water to the mixer, and then add 27 parts of α-amylase, 29 parts of pectinase, 17 parts of xylanase, 15 parts of laccase, 10 parts of cellulase, β- Add 3 parts of dextranase, 11 parts of ligninase, and 8 parts of lipase into the mixer, mix evenly, and prepare a slurry of 110g / L, and then grind it to the particle size with a grinder at 20-25°C 0.3 ~ 0.4 μm, that is, get the complex biological enzyme;

[0050] b) Contains 15g / L compound biological enzyme prepared in step a), 8g / L osmotic emulsification detergent, 10g / L ethylenediaminetetraace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com