A kind of ceramsite containing gasification slag and preparation method thereof

A slag and ceramsite technology is applied in the field of ceramsite containing gasification slag and its preparation, which can solve the problems of gasification slag discarding and environmental pollution, and achieve the effects of avoiding ceramsite crushing, low crushing rate and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

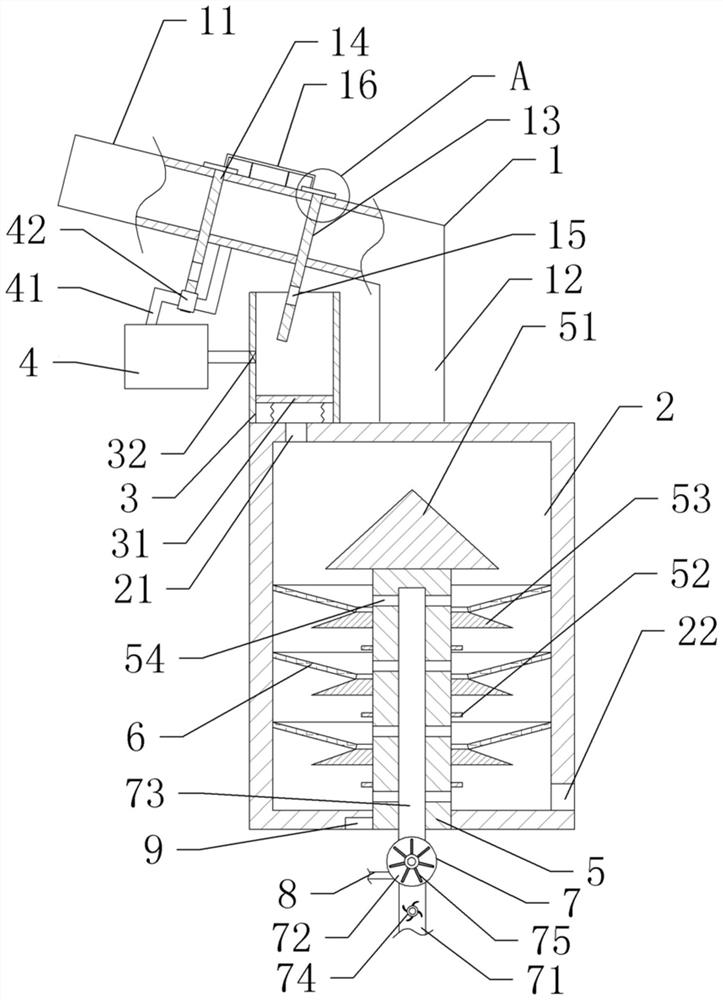

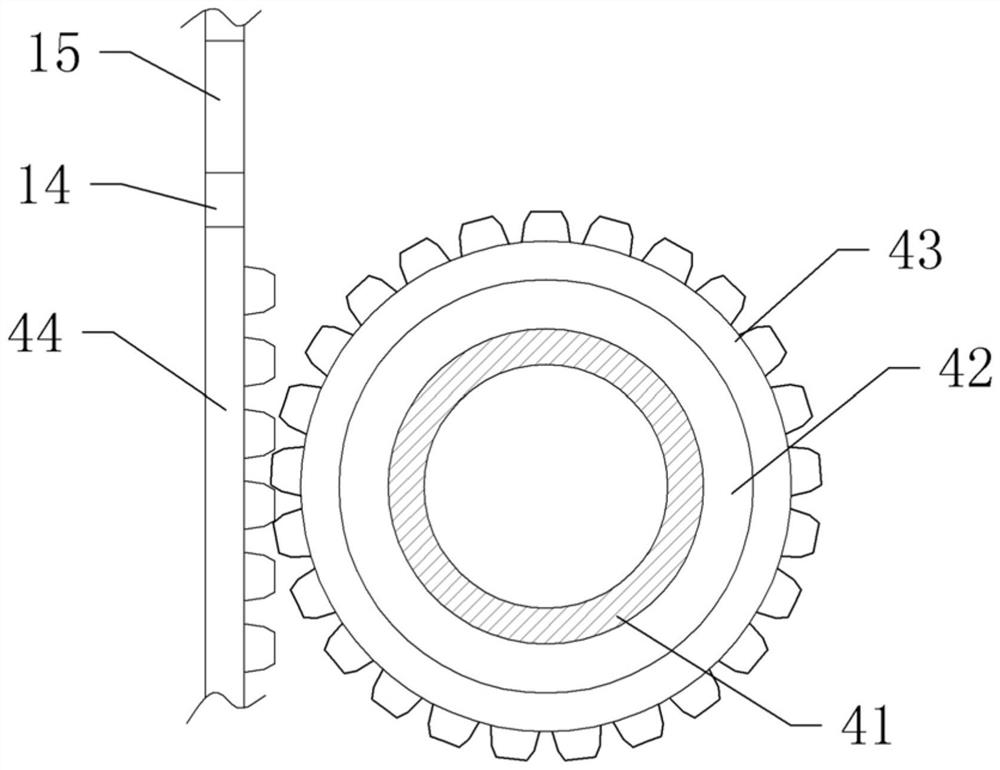

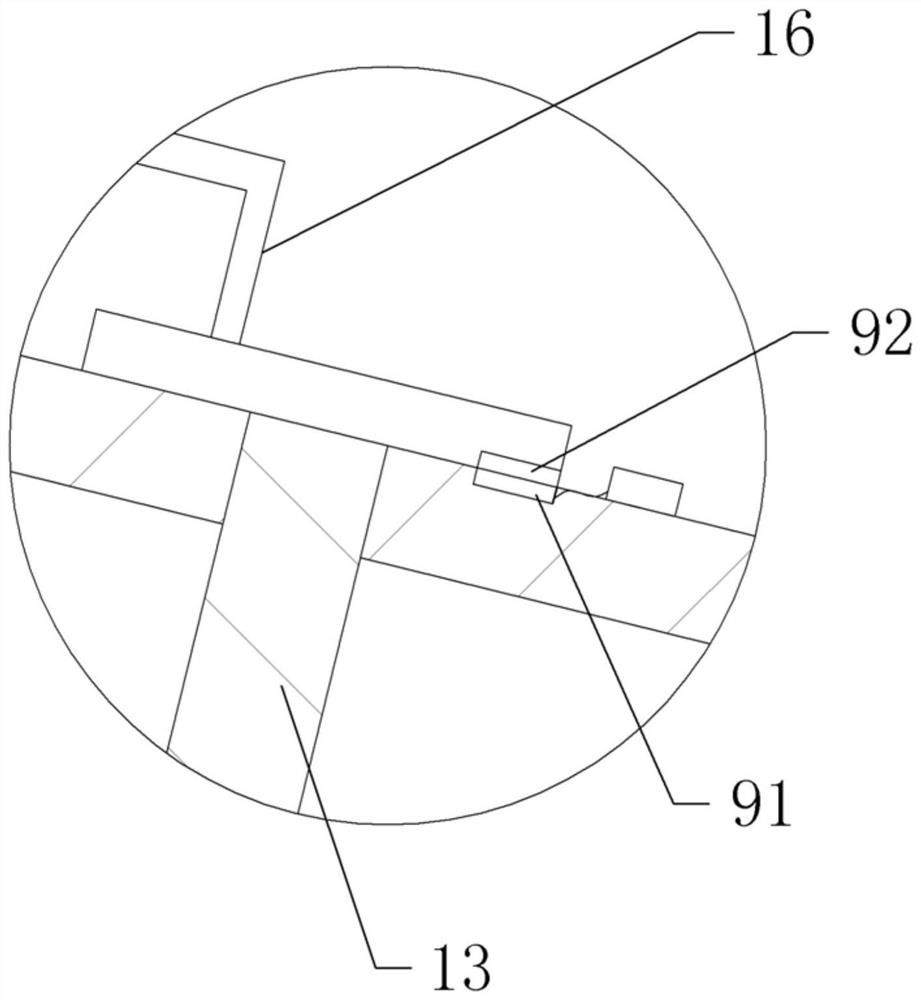

[0042] A preparation method of ceramsite containing gasification slag, comprising the following steps:

[0043] Step 1, use a crusher to crush the gasification slag so that the particle size of the gasification filter residue is less than 3mm and reserve it for later use, and fully mix the spare gasification slag with the mixture of clay and B4C modified phenolic resin adhesive to form a mixture Material spare.

[0044] Step 2, mixing the mixed material with water, and the weight ratio of the mixed material and water is 1:1, and using a granulator to make the mixed material mixed with water into a raw meal with a diameter of 10-12mm.

[0045] Step 3: Dry the raw meal at a temperature of 610° C. for 10 minutes to achieve preheating of the raw meal and avoid the occurrence of raw meal breakage caused by direct calcination of the raw meal.

[0046] Step 4: Use a calcination device to calcine the dried raw material. The calcination temperature is 1280° C., and the calcination tim...

Embodiment 1

[0068] The only difference between Example 1 and Examples 2-8 lies in the parameters shown in Table 1.

[0069] experiment:

[0070] Each parameter of comparative example 1-8 is as shown in table 2:

[0071] Table 2

[0072]

[0073]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com