Self-repairing chitosan hydrogel corrosion-resistant coating and synthetic method thereof

An anti-corrosion coating and self-repairing technology, applied in anti-corrosion coatings, chitin polysaccharide coatings, polyester coatings, etc., can solve problems such as damage, small cracks, coating failure, etc., to avoid corrosion, improve corrosion resistance and durability properties, good water absorption and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Self-healing chitosan hydrogel anti-corrosion coating, prepared from component A and component B;

[0027] Specific steps are as follows:

[0028] (1) Configure component A: mix 1.50g polyglutamic acid, 0.80g polyvinyl alcohol and 20g deionized water, and stir at room temperature for 45 minutes to make the solution evenly mixed;

[0029] (2) Prepare component B: mix 1.00g chitosan, 0.10g 1,2,4-triazole and 10g deionized water, stir at room temperature for 30 minutes, and mix thoroughly to obtain component B;

[0030] (3) Mix components A and B according to a mass ratio of 1:1, and mechanically stir at room temperature to obtain a self-repairing chitosan hydrogel anticorrosion coating.

[0031] The above-mentioned environment-friendly self-healing hydrogel anti-corrosion coating is subjected to a performance test:

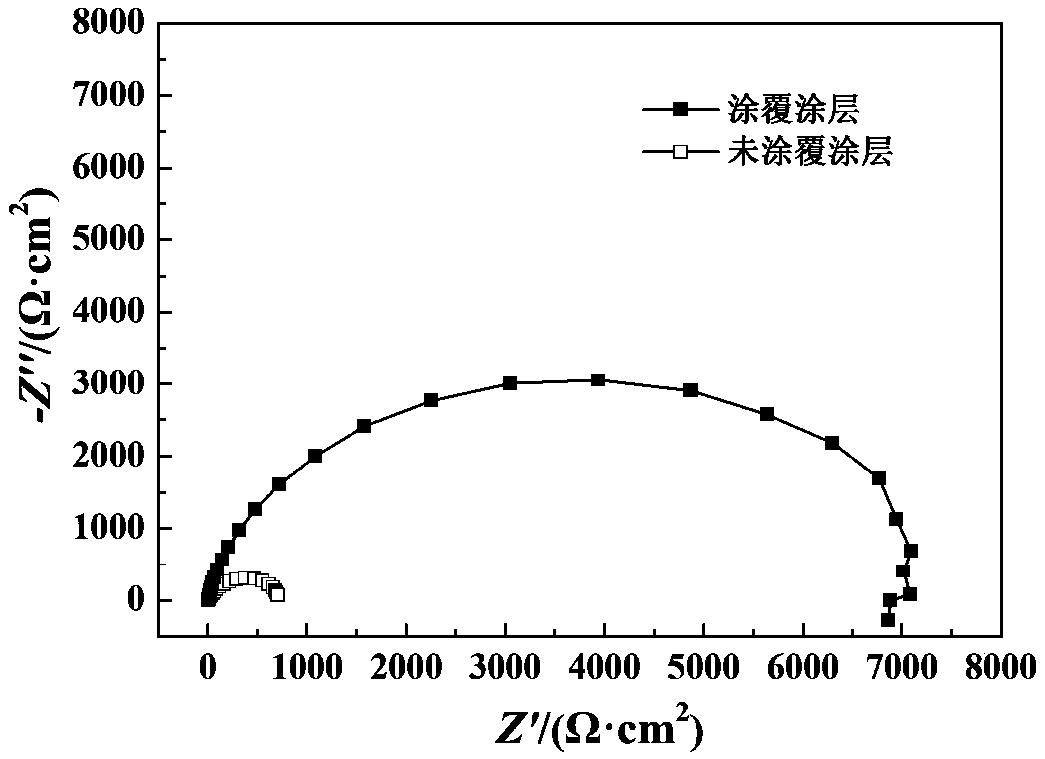

[0032] The above-mentioned hydrogel anticorrosion coating is coated on the surface of the Q235 steel electrode, then soaked in simulated seawater, and an e...

Embodiment 2

[0034] Self-healing chitosan hydrogel anti-corrosion coating, prepared from component A and component B;

[0035] Specific steps are as follows:

[0036] (1) Configure component A: mix 0.80g polyglutamic acid, 0.80g polyalkylcyanoacrylate, 1.20g alginic acid and 25g deionized water, and stir at room temperature for 45 minutes to make the solution evenly mixed;

[0037] (2) Configure component B: mix 2.00g chitosan, 0.150g 2-mercaptobenzothiazole and 15g deionized water, stir at room temperature for 30 minutes, and mix thoroughly to obtain component B;

[0038] (3) Mix components A and B according to a mass ratio of 1:1, and mechanically stir at room temperature to obtain a self-repairing chitosan hydrogel anticorrosion coating.

[0039] The above-mentioned environment-friendly self-healing hydrogel anti-corrosion coating is subjected to a performance test:

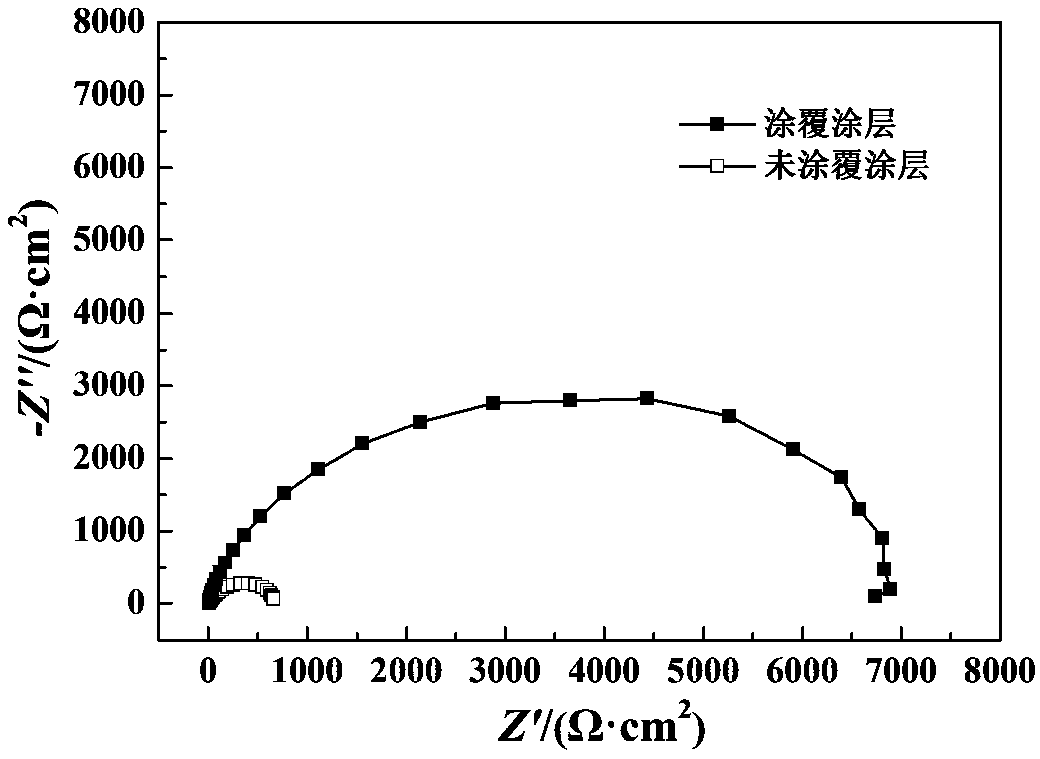

[0040] The above-mentioned hydrogel anticorrosion coating is coated on the surface of the Q235 steel electrode, then s...

Embodiment 3

[0043] Self-healing chitosan hydrogel anti-corrosion coating, prepared from component A and component B;

[0044] Specific steps are as follows:

[0045] (1) Configure component A: Mix 2.50g polylactic acid, 0.80g carboxymethyl cellulose, 0.80g polyvinyl alcohol and 30g deionized water, and stir at room temperature for 45 minutes to make the solution evenly mixed;

[0046] (2) Configure component B: mix 1.00g chitosan, 0.10g dibenzothiazole disulfide and 15g deionized water, stir at room temperature for 30 minutes, and mix thoroughly to obtain component B;

[0047] (3) Mix components A and B at a mass ratio of 1:1.5, and mechanically stir at room temperature to obtain self-repairing chitosan hydrogel anticorrosion coating.

[0048] The above-mentioned environment-friendly self-healing hydrogel anti-corrosion coating is subjected to a performance test:

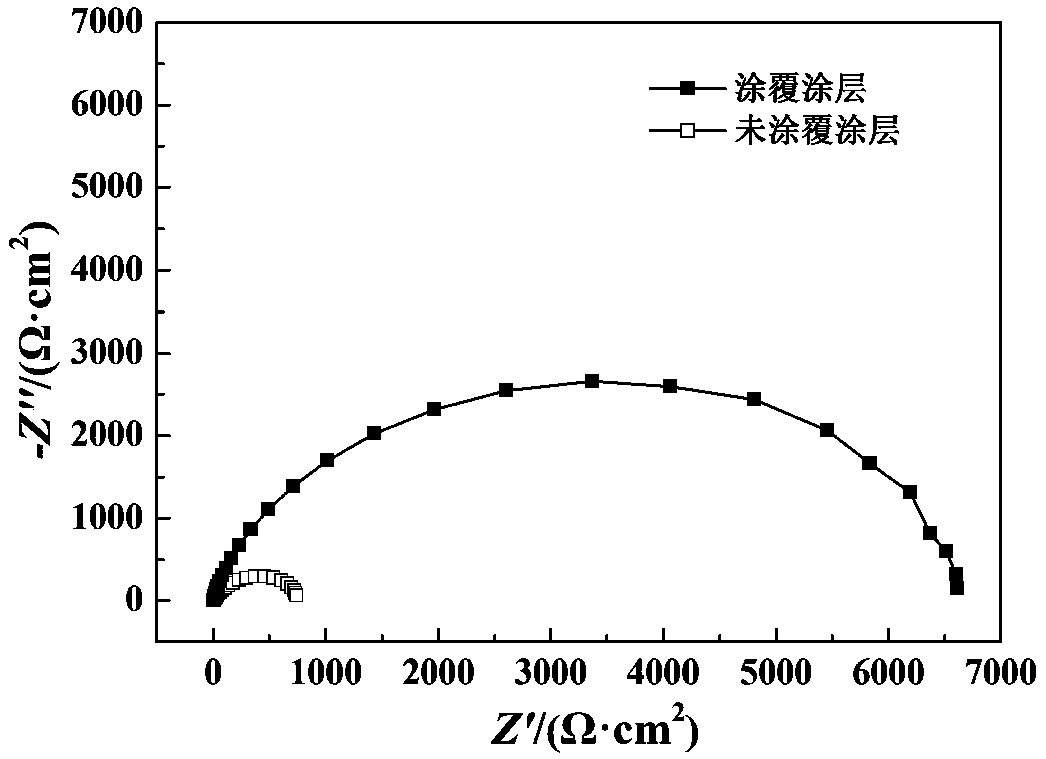

[0049] The above-mentioned hydrogel anticorrosion coating is coated on the surface of the Q235 steel electrode, then soaked...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com